Cummins: hydrogen ICE ignites customer interest at China Tech Day

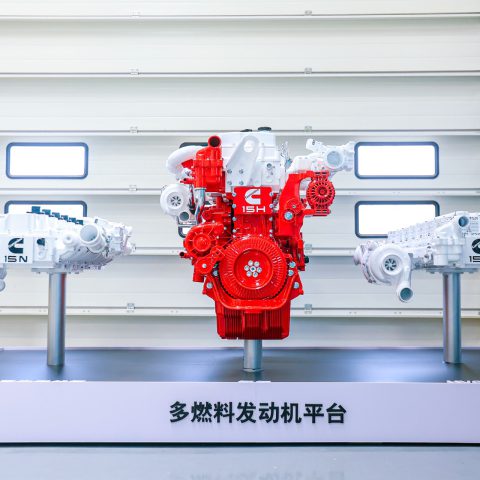

The event at Cummins’ East Asia Research & Development Centre showcased the company’s latest product strategy for China-based customers, focusing on the China debut of its 15-litre hydrogen internal combustion engine. Meritor axles, Eaton Cummins Endurant transmissions and Cummins aftertreatment systems were also on display.

Cummins has demonstrated its commitment to low- and zero-carbon technologies at a Technology Day in Wuhan, China. The event at Cummins’ East Asia Research & Development Centre showcased the company’s latest product strategy for China-based customers, focusing on the China debut of its 15-litre hydrogen internal combustion engine. Meritor axles, Eaton Cummins Endurant transmissions and Cummins aftertreatment systems were also on display, highlighting the company’s commitment to provide a broader range of products, as well as full powertrain integration capabilities.

The event signalled the introduction of Cummins’ X15H hydrogen internal combustion engine and attendees witnessed its first start-up in China. Part of the company’s industry-first fuel agnostic engine platform, Cummins’ 15-litre hydrogen engine features direct-injection, lean-burn combustion, with ratings up to 542 hp and peak torque of 2600Nm. The zero-carbon fuel hydrogen engine can achieve brake thermal efficiency (BTE) up to 44% with brake mean effective pressure (BMEP) of 22Bar, supporting diesel-like power and torque capability.

Jason Wang, Cummins VP & General Manager of EBU China, said, “Achieving zero-carbon requires collaboration and joint innovation. Cummins has long-term partnerships with its Chinese customers which allows us to fully understand their business requirements and sustainability goals. The combination of in-depth market insights and a culture of innovation well-positions Cummins to develop the right solutions that support our customers’ businesses while reducing environmental impact.”

Cummins X15H hydrogen engine is based on familiar internal combustion engine technology and can be integrated into a vehicle chassis without the need for a major product redesign. Its diesel-like performance means it’s a viable zero-carbon fuel option for many applications, including heavy-duty haulage and vocational trucks. Commonality between the X15H and its diesel counterparts also supports existing parts supply and maintenance practices.

Cummins is investing a total of $150m in its East Asia Research & Development Centre to enable further development of internal combustion engine technology as well as zero-emissions products. The new facility covers an area of 78,000 square metres with 28 test cells and a building dedicated to zero-emissions power. The Centre has contributed to more than 50 new product introduction programs so far.