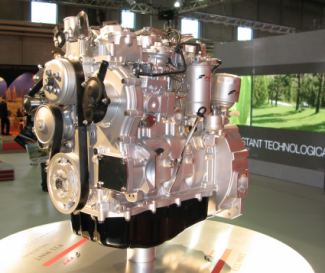

F28 likes compact off-road machinery

F28 and F32, two acronyms that describe the trajectory of FPT Industrial among OEM industrial applications. With one difference: this trajectory has evolved from downsizing to rightsizing. We publish the second part of the interview with Marco Bellomia, Platform Manager F28, F5 & S8000 engines. Also for F28 waste gate and blow-by are still the […]

F28 and F32, two acronyms that describe the trajectory of FPT Industrial among OEM industrial applications. With one difference: this trajectory has evolved from downsizing to rightsizing. We publish the second part of the interview with Marco Bellomia, Platform Manager F28, F5 & S8000 engines.

Also for F28 waste gate and blow-by are still the best choice in terms of quality – price ratio?

The waste gate is the entry-level entry for such an engine, which could also be equipped with a turbine with a more sophisticated control valve (like the VGT), but the cost-benefit ratio still favours the waste gate turbocharger. The treatment of blow-by gases remains a fundamental requirement for Stage V and Tier4F regulations.

Compared to F32, the blow-by filter is positioned on the engine head, in a sheltered position with respect to the fan. In this way, we have a solution that reconciles a long life cycle and adapts to high degrees of inclination, congenial to the needs of off-road applications.

How has the perception of OEMs evolved? After 12 years, competition from the electrical sector on small construction machinery has become stronger. Are the NG and hybrid versions of the F28 the answer?

The specialized tractors market moves according to the demands of farmers, reduction in height from the ground and maximum compactness to favour manoeuvrability: these are demands that will never have an insurmountable limit, due to the needs of end users. All specialist ranges are moving in this direction, including those of the CNH Industrial Group. Like FPT Industrial we have ‘market ready’ gas solutions on the on-road side and also gas-powered tractors, compatible with sustainable agriculture through biogas. On mini-excavators we are moving towards 100 percent electric. How do we understand electrification? Surely it is linked to improving transient responses, essentially an incentive to performance and reduced consumption.

The 2.8 litre cubic capacity occupies a power range that could threaten that of 3.4 – 3.6 litres. Could the 2.8 could make the competition checkmate with a more performing battery pack, thus approaching 80-90 kilowatts?

The basic idea is that, probably not up to 90 kilowatts, but with 75-80 kilowatts you would have performance in line with what you say and with a significant reduction in consumption. In a second phase, we are considering the possibility, for certain applications, of working at zero emissions in indoor environments.

Going back to the starting point and looking at the issue through the eyes of an OEM, how has the demand for engines from manufacturers of off-road machines in the range covered by the F28 changed?

While previously there was a big push to increase performance, now everyone is looking for a compromise between compactness and cost, without penalising performance.

In addition, the integration and compactness of exhaust gas treatment systems are a fundamental driver and FPT supplies three different solutions for housing the ATS with the F28: on the flywheel cover (which does not come out of the flywheel cover template), mounted longitudinally at the head or a more flexible remote version for constructing equipment installations.