John Deere at ConExpo

They are all there: starting with the JD4, the 3.9 which relaunches the quotations of the Deer among the contacts, and the 18-litre, Diesel of the Year 2021. We continue with the first fruits of the synergy with Kreisel: electric drives, inverters and a diverse portfolio of batteries.

The winds of renewal are also blowing in Saran and Waterloo. Which, in the case of John Deere Power Systems, bears the name of Kreisel. “We see a clear and growing need for batteries and charging solutions for the off-highway sector. For this reason, we are leveraging our engineering expertise to innovate on behalf of our customers and bring the strongest, most durable products to market,” said Jennifer Preston, global director, John Deere Electric Power. “Together with Kreisel, we are expanding our battery portfolio to include even more versatile and scalable power and meet a wider range of application needs as we continue to work towards a future with zero-emission propulsion and pursue our goal to demonstrate near-zero carbon energy solutions by 2026.” Another star that stands out brilliantly in the American firmament has the joint signature of Deutz and John Deere at its bottom.

The first cries (and roars…) of the 3.9-litre

It’s called JD4, in John Deere’s onomastics: 3.9 liter cylinders (BxS, 99 x 120 mm), with 2 valves per cylinder, from 63 to 120 kW, guaranteed maintenance intervals no earlier than 750 operating hours. We grabbed a comprehensive overview of the stand, drawing from the availability of the various product managers, and we started from here. “We have equipped ourselves with a specific injection system, we have customized the electronic control and the post-treatment. The philosophy behind this project lies in the compact engine, with a conventionally 800/900 cc barrel, the result of a significant update compared to the average (the JD4 barrel measures 975 cc, therefore very close to a return to the old, the “mythologized” thousand cane, ed.); power density has certainly raised the bar. It will replace some of the 4.5-litre calibrations also in function of this. We are really preparing for the next challenges with renewed hardware that allows us to do what we currently cannot do on the 4.5-litre. The main features concern the supercharging, with wastegate valve, the common rail, specific to our solution, as well as the approach in terms of electronic control. Among the customizations, I add the fuel system, the air system, the injection pressure.”

The JD4 will compete with its red painted counterpart, while satisfying the insatiable appetites of the large domestic patrol. Once again the post-treatment proves to be decisive in defining the dimensions. The John Deere family has basically stayed true to itself since phase 3 of the EU and EPA regulations. Crossing the significant and airy arena of Jdps, we intercept the JD14, the 13.6-litre, this too recovering from the slimming cure of engineering which has optimized the overall dimensions, compared to the previous 13.5-litre, and simplified integration on board the machine .

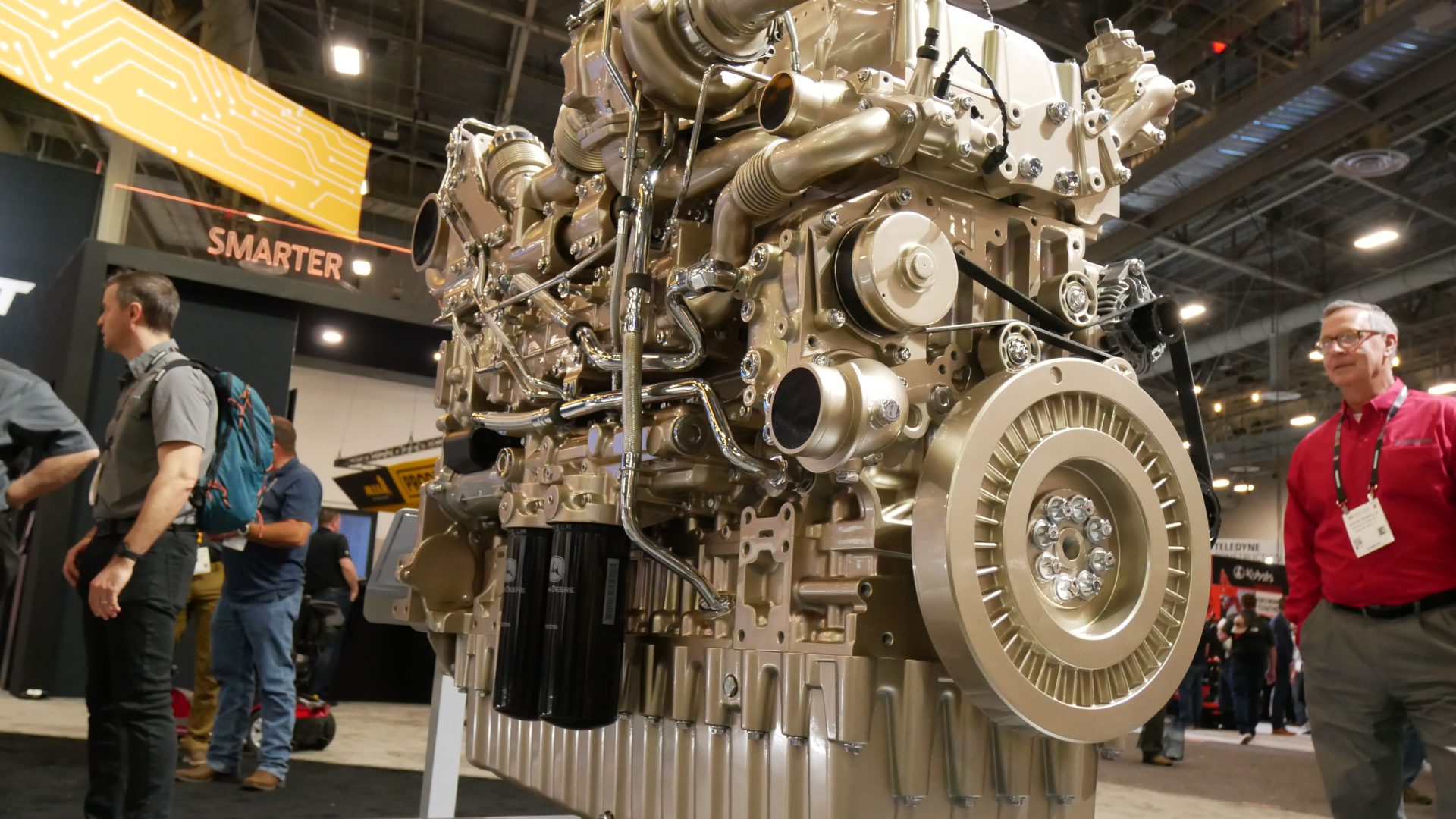

JD14 and JD18

Speaking of this engine, which anticipated the renewal of the family, we remind you of the words spent at Agritechnica 2019 by Patrick Thil, Manager, Oem Sales, Eame, Asia and Australia. “With the 13.6 liter we can reach up to 510 kilowatts, that is almost 700 horsepower. We modified the injection system to have higher fuel pressure and achieve the desired horsepower. Originally the injection unit was located inside the engine and we placed the common rail on the outside of the engine cover. We took the opportunity to change the engine head a bit, reducing its size and integrating some automatic valve adjustments. We have also improved the noise level and simplified maintenance.”

We integrate what is reported with the confirmation of the external EGR. The Deer remains faithful to the principle of modularity and sharing of components to facilitate assistance for machine builders and users, training for dealers and workshops. Another milestone of John Deere 2.0 is the rear gear train, which reduces noise and torsional and crankshaft stresses. Hydraulic adjusters reduce valve clearance. A “government program” that also involved the JD18, Diesel of the Year 2021, which has a range between 522 and 677 kilowatts.

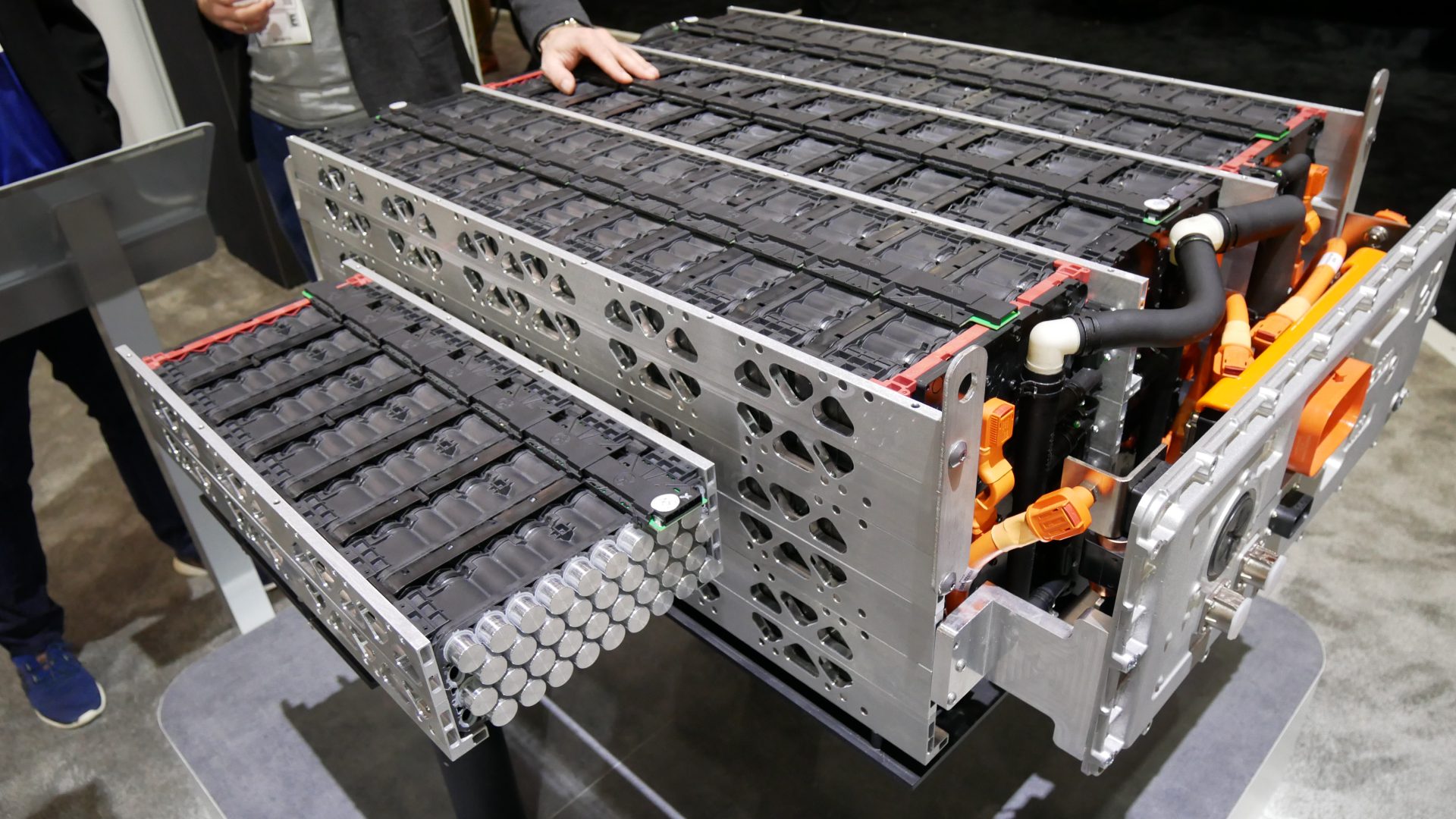

Let’s review the concrete manifestations of the entry with a majority stake in the Austrian Kreisel, dating back to the end of 2021. Let’s start with KVP63. The battery nomenclature identifies the power, expressed in kWh; in production, therefore orderable, puts the trump card of morphology on the table, meaning therefore the shape of the battery pack, to facilitate housing and integration in certain types of applications, both hybrid and electric. The electric offer does not end here, which continues with a triptych of batteries capable of satisfying the needs of applications such as light towers in the power range from 20 to 40 kilowatts. We also saw the EMD-200-D electric motors, up to 200 kW and 1,275 Newton meters, the EPD-200 electric drive, 200 kW and 881 Nm, the EMD-100-1, single speed electric motor, with inverter PD400, from 326 kVA (the Pd280 reaches 228 kVA).

Like Lego bricks

The idea gathered during the “promenade” between the traction and power devices is interesting, which compares the modularity of the batteries to the logic of Lego bricks. “Technology moves forward” is a popular adage that fits John Deere’s tactic as never before. The thermal management of the batteries is one of the parameters for evaluating the synergy with Kreisel, with a view to providing performance in line with the consequent increase in power and duration. The catchphrase of power density, “mutatis mutandis”, also reverberates in the new world of electrification. “You can do a slow top-up» they tell us, “but you can opt for a fast top-up, for example during a lunch break, using the network.” Therefore, no substations, high voltage current, permits are required.

What is written supports the statement of Jennifer Preston, global director of John Deere Electric Power, who anticipated the opening of the ConExpo: “We see a clear and growing need for batteries and recharging solutions for the off-highway sector. Together with Kreisel, we are expanding our battery portfolio to include even more versatile and scalable power to meet a wider range of application needs.”