Kubota at Agritechnica: the hybrid family is growing

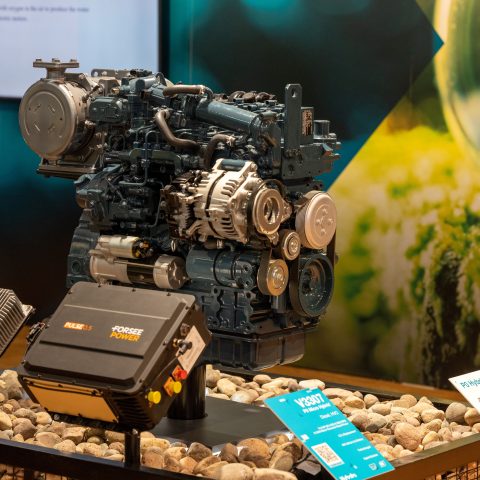

The enhancement of Kubota’s micro-hybrid offering is ongoing. At Agritechnica from Osaka they will bring the V3307-CR-T P0 Micro Hybrid and the D1803-CR-T P1 Hybrid. On display also the Kubota 3.8L Hydrogen Engine

Daniel Grant and Ko Shiozaki told us at Conexpo: “In our ICE strategy we are focusing on an increasing efficiency, adaptability of the fuel engines solutions, we also have a fuel solution, where we’re looking at promoting technology to reduce carbon footprint, like HVO, GTL or more synthetic fuels. Our hybrid strategy is complementing similar philosophy.”

A micro-hybrid solution had already made its first appearance at the Paris Intermat in 2018, and was better made explicit at Bauma Munich in 2019. A forklift truck flanked a lithium-ion battery and converter to the D1803CR-T, replacing the V2403CR-T. A downsizing operation and a significant reduction in CO2, as well as NOx and PM. Kubota is continuing its specialization in micro-hybrid at Agritechnica 2023: an approach that respects application footprints, promotes ICE reliability and installs an electric fraction capable of delivering torque, rise and application versatility (e.g. indoor).

Summarizing, Kubota’s Hybrid Technology is a system installed with a 48-volt motor generator using electric power only when intermittent overloads need to be handled. A motor-assist function is used to deliver an extra, instantaneous 10 kW of electrical boost power when needed for occasional sudden loads enabling operators to select an engine with output to match the load range, together with electric power to compensate for infrequent intermittent overloads.

In Hanover we will be able to touch one of the best-selling engines. The 3.3-litre displacement, 4-cylinder, Kubota V3307-CR-T P0 Micro Hybrid has a rated power of 55.4 kW at 2600 rpm. As the P0 is the same size as the comparable common rail engine it is easy to install. It will be also in display a compact D1803-CR-T P1 Hybrid, which has an output of 37 kW at 2700 rpm. The AC synchronous motor generator is encased in the flywheel housing keeping engine size to a minimum and all necessary components, such as motors and 48 V lithium-ion batteries, are supplied by Kubota. This means that customer development resources can be minimised. A belt drive mechanism is not required thus increasing robustness and ease of maintenance. The 1.8L displacement P1 has a maximum torque of 150.5 Nm at 1600 rpm. The P1 features a direct injection combustion system and a common rail fuel system. For the P0 the micro-hybrid system is controlled by the ECU and not by signals from the vehicle. This is made possible by rewriting the software in the existing Electronic Control Unit of Kubota engines. No additional ECU is required for hybrid control. On the Kubota stand there will also be room for the 3.8L Hydrogen Engine, based on the spark-ignited type WG3800 engine. It is configured for agricultural specification. About hydrogen, Kubota is cooperating with another Japanese company, Denyo, in the development of a hydrogen-powered generator set.

Again Daniel Grant, Manager Marketing Intelligence for Kubota BU Engine Europe, says: “Our new range of hybrid and hydrogen engines are a perfect example of achieving carbon neutrality whilst, at the same time, helping machine designers and operators to benefit from both reduced maintenance demands and fuel consumption and also enhanced installation ease and machine design flexibility.” Focusing on the specific application in the spotlight at Agritechnica, tractors and agricultural machinery, Grant points out that: “As a comprehensive solutions provider for agriculture, Kubota offers technical back up and support at every stage for the farming sector. This ranges from developing agricultural machinery and providing engine choices that match day-to-day requirement.”