Perkins announces its complete range of 5000 Series electronic engines

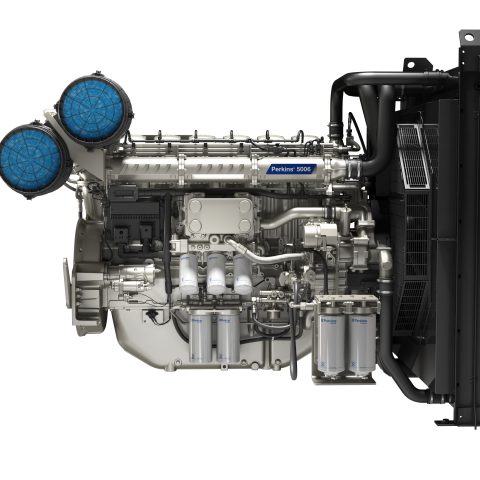

The all-new Perkins 5000 Series is a full authority electronic range of inline six and eight cylinder and V12 and V16 cylinder engines, engineered specifically for the power generation market to supply critical applications such as data centres and hospitals

The all-new Perkins 5000 Series is a full authority electronic range of inline six and eight cylinder and V12 and V16 cylinder engines, engineered specifically for the power generation market to supply critical applications such as data centres and hospitals with dependable prime or standby power, where downtime isn’t an option.

The most powerful and largest fully electronic, electric power range from Perkins, the 5000 Series has been designed to optimise customers’ needs for quick, reliable and cost-effective power, while delivering reliability, high performance and peace of mind.

Providing reliable power when needed, the 5000 Series delivers: outstanding load acceptance, response and performance, high power density in a smaller footprint for ease of installation, and a low cost of ownership with optimised fuel and oil consumption.

Perkins 5000: redefining performance in power generation

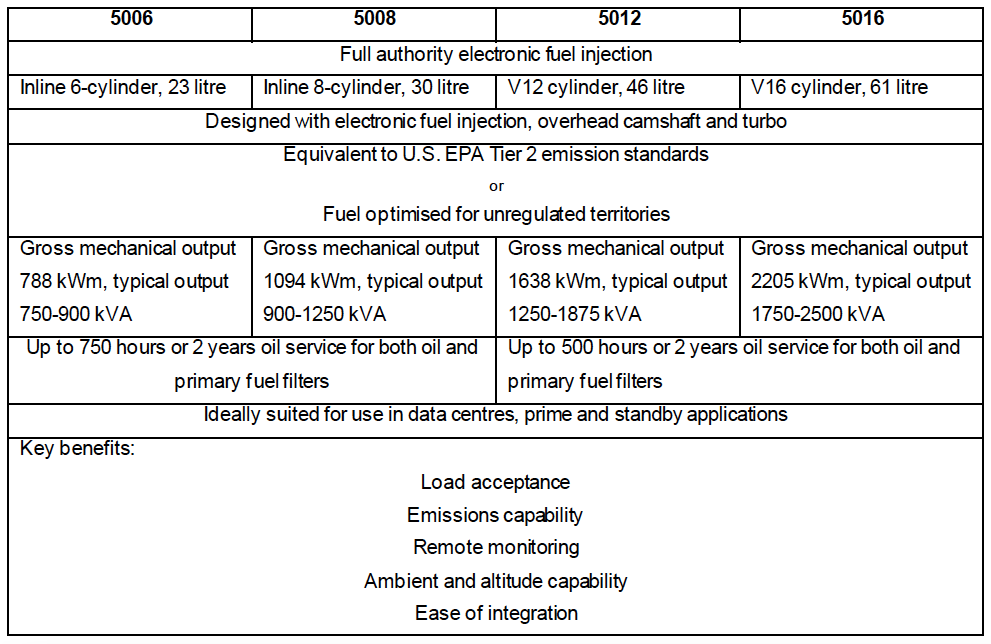

Ranging from 750 to 2500 kVA of power potential, the full authority electronic fuel injection 5000 Series engines are built to world-class standards for high efficiency, low fuel consumption and global emission standards.

Packed with features and the performance to provide dependable power output up to 2500 kVA for standby and 2250 kVA for prime applications, the 5000 Series is designed to supply electrical power when and where needed. Whether for critical power applications, or prime or standby power, the engine range has been optimised and tested to deliver cost-effective, reliable performance.

The next generation of electric power

“With multiple engine models offering a substantial power output of up to 2500 kVA, every aspect of the new 5000 Series engine range, from its outstanding load acceptance capabilities to custom-created components and innovative engineering techniques, has been designed to optimise our customers’ needs for quick, reliable and cost-effective power,” says EAME sales director Richard Hemmings. “In February 2021 we launched the first model in the series – the 5008C-E30TAG – into North America. I’m really excited that we’re now unveiling the complete range of six, eight, 12 and 16 cylinder variants which will be offered to our customers in Europe, Africa and the Middle East.”

Designed, engineered and built to provide dependable power for prime and standby installations including data centres and hospitals, the 5000 Series has been rigorously tested for performance and durability with more than 10,000 running hours already under its belt. With critical infrastructure at stake, the engine has been tested and proven in harsh environments.

Richard continues: “The 5000 Series is proven to be ready to deliver reliable power when it’s required, even in the most demanding working environments. And for applications where real estate is at a premium, such as in a hospital, the high-power density of the 5000 Series provides a compact design that packs power into a small, compact footprint.”

Optimised for load acceptance

Optimised turbochargers enable the 5000 Series engines to deliver outstanding load acceptance – meeting ISO 8528-5 G2 and G3 standards – and the ability to accept NFPA 100 percent block load. All of this means that the 5000 Series achieves full recovery after first load step within 13 seconds.

“The engine’s ability to very quickly deliver stable backup power is a vital requirement for critical applications like data centres and hospitals,” said 5000 Series product manager, Steve Chesworth. “Drawn on nine decades of engine-design and manufacturing expertise, the 5000 Series has been designed from the ground up and is the culmination of many years of research, development and rigorous testing. We’re confident this engine range will exceed our customers’ expectations.”

Designed with sustainability in mind

Engineered to be capable to Epa Tier 2 emission standards, the 5000 Series engines ensure your generator set is futureproofed with sustainability in mind. The core engine design features newly designed electronic fuel injectors to reduce exhaust emissions.

For generator manufacturers and end users looking to reduce their carbon emissions, the 5000 Series can run with biodiesel up to B20, based on a 20 percent dilution of biodiesel with standard diesel or on 100 percent hydrotreated vegetable oil (HVO) to EN15940 as detailed in the Perkins 5000 Series Operation and Maintenance Manual.

End users can lower their owning and operating costs by taking advantage of the telematics capabilities on the 5000 Series. Engineered with an integrated engine control module (ECM) and sensor pack, the compact package easily integrates with existing telematic ecosystems to enable remote monitoring through a third-party solution, allowing operators to easily track both the generator and engine.

The 5000 Series engines decrease fluid consumption and extend service intervals with redesigned parts including new piston rings and liner assembly, electronic fuel system and fuel filters to deliver a long-life span and improved efficiency to minimise the total cost of operation.