Scania’s three electric machines

The legendary Scania V8, the Super engines and the urban workhorse: now these internal combustion engines have met their matches in the battery-electric world.

You may know one of them as King of the Road – Scania’s legendary V8 engine that for more than 50 years has dominated the heavy truck segment. Another one you’ll know as Scania Super – the powertrain that has pushed the boundaries for fuel efficiency to the point that it has already earned two Green Truck Awards. And the third is called the “urban workhorse” – the flexible engine that is ideal for operations in urban environments. But now these internal combustion engines have met their matches in the battery-electric world.

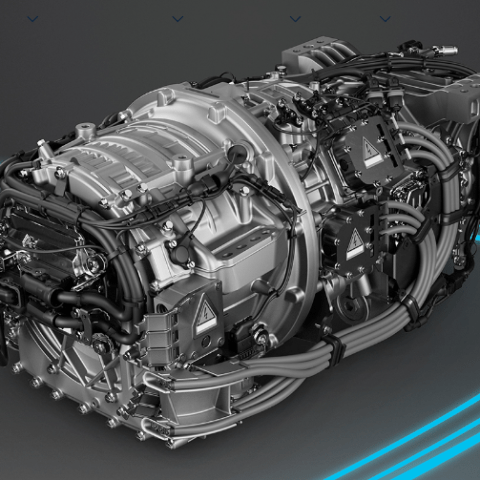

Scania EM C3-6, “the electric V8”

Scania’s C3-6 e-machine is the electric equivalent of the company’s legendary V8 engine. It is a powertrain for maximum performance, for a broad width of specifications and for high train weights. It comes in two different power ratings: 400 and 450 kW.

“It’s the first choice when you need that little bit extra,” says Fredrik Sundén, an e-mobility developer at Scania Research & Development. “The C3-6 stands out from the competition through its power, uninterrupted torque during gearshifts and acceleration performance. The combined driving sensation of these characteristics is unique and makes Scania stand out from the crowd,” he adds.

The design features three electric machines and a six-speed gearbox with double input shafts.

“This means we can continue to propel the vehicle forward while shifting gears; two of the electric machines propel the vehicle, while the third synchronises the next gear,” says Sundén. “The dual input shafts also allow us to offer a versatile Power Take Off programme (PTO). One input shaft can drive the PTO while the other drives the vehicle, making PTO possible both at standstill and when driving.”

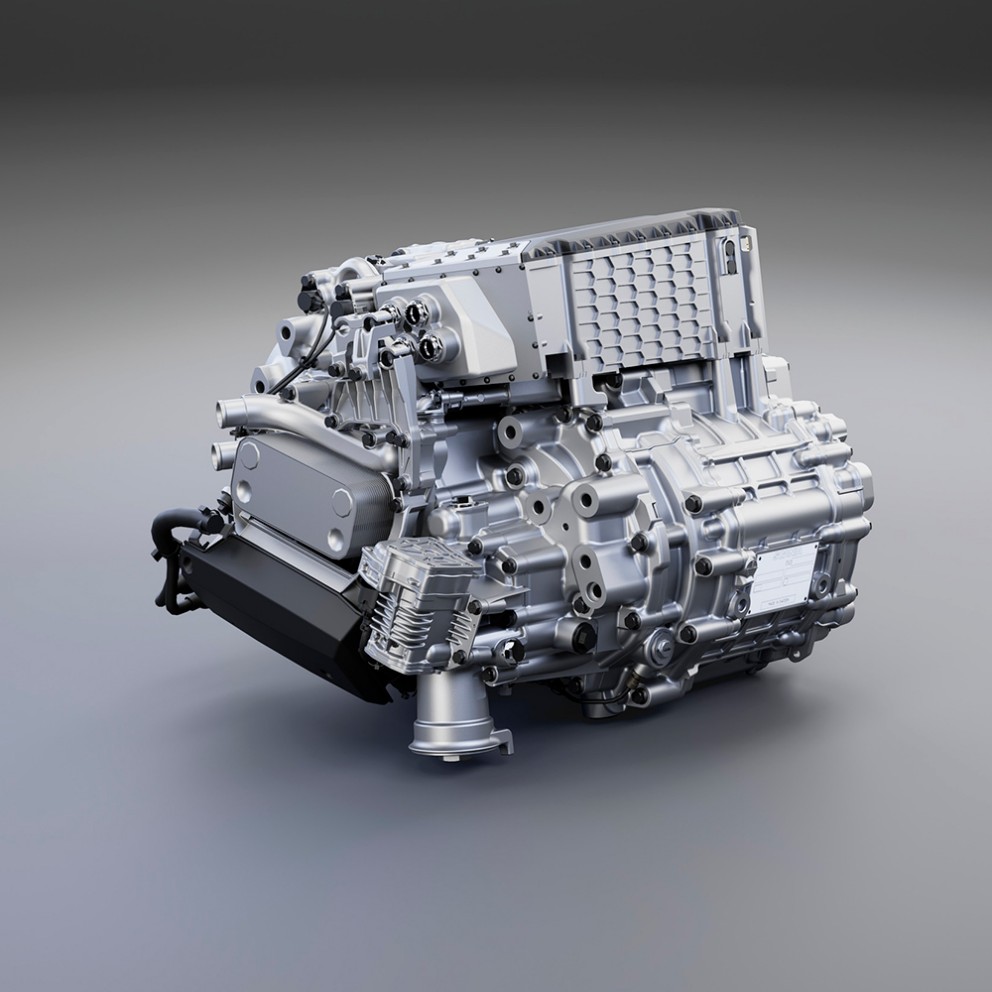

EM C1-4, the “electric Scania Super”

The versatile C1-4 e-machine corresponds to a six-cylinder Scania Super with its state-of-the-art fuel consumption. It’s the go-to choice for a 40-tonne tractor-trailer combination on the autobahn. But with power ratings from 270 to 400 kW and a four-speed gearbox, it also has unmatched performance for a vast number of medium weight transport tasks.

This e-machine also feature new updated technology, an inverter for increased efficiency and a mechanical PTO which enables power take off when the vehicle is stationary.“The C1-4 is a drive unit which we have tailored for future requirements for weight, efficiency and installation. The powertrain is well-balanced and offered in several performance stages to suit any application,” says Sundén.

Scania EM C1-2, the “electric urban workhorse”

The EM C1-2 is physically shorter than its more powerful e-siblings. With two versions available – 210 kW and 240 kW – it is the perfect all-rounder for lighter operations, combining low weight with high power output, lots of torque and smooth power delivery with two gears. It is ideal for distribution operations in urban environments, but equally suited for many other applications such as the diverse kinds of vehicles that municipalities use.

“If we were to do a diesel comparison, it would be the equivalent of a 9-litre engine,” says Sundén. “Compared with a conventional ICE powertrain, the controllability of the new two-speed electric machine provides a major advantage. In operational conditions, the driver will experience a more nuanced and direct driving experience, a faster response, faster acceleration and a smoother feel from the powertrain.”

Why Scania has chosen a centrally placed e-machine

Common to all three present Scania e-machines is that they are centrally placed in the vehicle construction. The power from the electric machine is sent to the wheels via the propeller shaft through a differential and a set of axles. An alternative technical solution would be an e-axle that integrates an electric motor, power electronics and gearbox into one unit, directly powering the wheels.

“Ultimately, it depends on the application as to which solution suits best. At Scania we believe that a centrally placed e-machine is the most flexible and efficient solution at the moment,” says Hans Petersson, Senior Product Manager within Scania e-Trucks. An e-axle solution has its potential pros in terms of weight and freeing up space in the frame, but it also has its cons, according to Petersson.

“Having more unsuspended weight and lower ground clearance means that an e-axle could work well on flat highways but not on uneven or rough roads. The e-axle solution could also mean less loading capacity, and the PTO possibilities are limited.”