FPT Industrial: interview with Alice Orsi, the ePowertrain lady

At ACT Expo, FPT Industrial will be able to show off its e-driveline milestones. A portfolio that includes electric axle, central drive and electric drive unit. XC13 will also be there. We interviewed Alice Orsi, Head of ePowertrain marketing & product portfolio. Read the full article in the May issue of POWERTRAIN International.

The e-plant in Turin is in full swing. FPT Industrial presides over US trade fairs where innovation is the driver. After CES, it will land again in Vegas, at the ACT Expo. Read the words of Alice Orsi, Head of ePowertrain marketing & product portfolio.

What prospects do you see for onroad globally?

“In order to develop a global argument, we must first take a step back into the history of FPT Industrial’s ePowertrain. For the past five years or so, we have taken up the challenge of electric technology, with some milestones in our journey, including the partnership with Microvast on batteries and the acquisition of Potenza Technologies in the UK. This laid the foundations for the establishment of a research centre that is linked to the design and development of the battery management system, the brain of the battery pack. In a very short time, we have positioned ourselves as the full liner of electrification, so much so that at the IAA – two years ago – we presented a first generation of axles, a complete line. In the partnerships with Maserati and Iveco, we have shown our expertise. The road map is clear. On the one hand, we continue to invest in thermal and traditional engines, in their various forms, biofuel and hydrogen. On the other, there is electrification, on which we are positioning ourselves as a supplier of zero-emission solutions, and this concerns the global market. In Europe, through Iveco, but also in China and North America, which are important markets and play a key role in electric propulsion. As ePowertrain, and not only that, we look at hydrogen, including fuel cells, not just H2 ICEs. In our R&D centre in Arbon, we have test benches and a team of engineers dedicated to fuel cells. A solution that will become established later in the timeline. As far as segments are concerned, looking at the European market, electrification in the light vehicle industry follows what is happening in the automotive industry. It also increasingly concerns medium and heavy-duty vehicles, which from 2035 will see other technologies take over, typically hydrogen, in both declinations, endothermic and fuel cell. With light vehicles, the thrust comes from both legislation and TCO, for medium and heavy vehicles the thrust is mainly legislative, and in any case, it also concerns other world markets. We follow a project to develop electrified solutions across the board, applicable to all segments (light, medium, heavy vehicles and buses).”

In the US, are heavy vehicles aiming at electrification, hydrogen or is there room for LNG? What similarities are there between what you are exhibiting in Vegas and Hanover?

“Alternatives were also seen at last year’s ACT Expo. However, the US has quite an infrastructure challenge ahead; especially for electric mobility, which is imminent. Regarding the common thread with the European ecosystem, the première of the second generation of electric axles will be on display at ACT. We do believe in this technology for reasons of compactness and efficiency, two of the three elements of the “fil rouge” that connects the European and American worlds. The third point, and one of the pillars of FPT, is sustainability, which is intrinsic to the concept of electrification. We have other innovations in store. Some are oriented towards the American medium and heavy-duty market, including 6x4s with two trailing axles. Axles are related to propulsion flexibility, so there is no reason to think that a product cannot fit both a BEV and a fuel cell vehicle. Hydrogen designed for thermal engines lends itself to applications tuned to certain emission profiles, such as those of heavy-duty vehicles.”

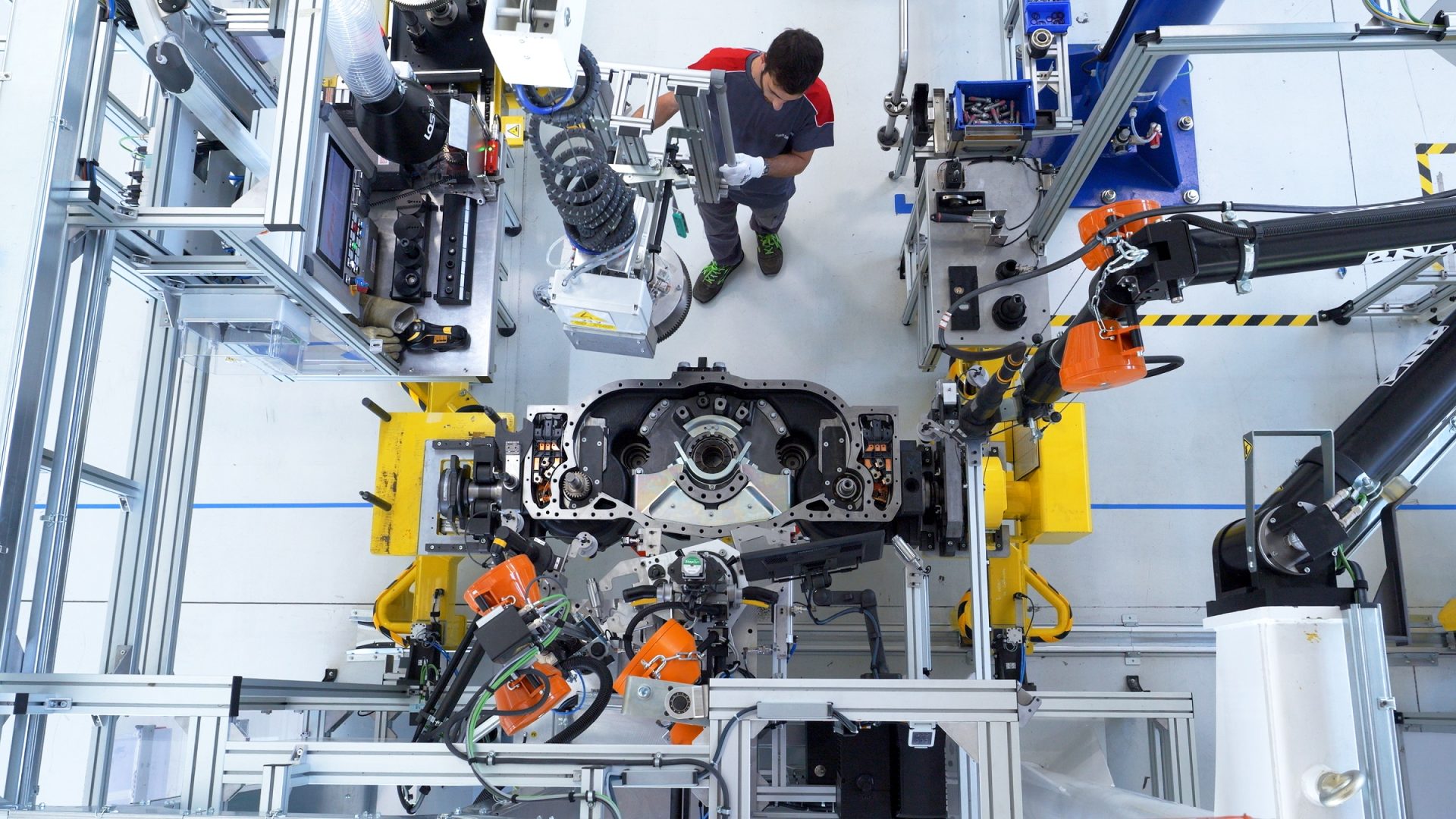

How strategic is the electrified axle asset for FPT Industrial?

“The first generation of ePowertrain was created to meet the needs of Iveco, our internal customer. We focused on propulsion, hence on eDriveline. We are able to develop all three types of drivelinesalso with on the market: the electric axle, the central drive, for example the Daily’s, which allows us to electrify even non-native vehicles, and the electric drive unit, like the one in Maserati. So, we are talking about suspended “objects”. In today’s electrification scenario, FPT has the expertise to develop the three types of drivelines. We are continuing with the development of electric axles. These are our main focus, for the aforementioned reasons of compactness and efficiency. Also, with regard to energy storage, FPT has products developed with Iveco Truck and Iveco Bus, for the two battery packs on the Daily. Two products that – as first generation – we can consider state of the art.”

What about the second life project with Reefilla?

“I know it well, having been part of the project’s team of initiators and implementers. One of the first challenges we faced was to find a solution to the sustainability of battery packs. When we talked about the projects of this Turin-based start-up, we were in agreement. The objects made by Reefilla are in the embryonic stage, made from FPT Industrial second life batteries, which have been identified as no longer suitable for vehicular traction. With the Reefilla team, a product was designed that had the capacity to accommodate almost all the modules of the battery pack, and more than 50 percent of the lose parts. We are all well aware of the sustainability criteria of the module containing the chemistry. However, some forget those components that it would be optimal to reuse, without adding processes. The Fillee is a portable storage system created with a shape factor. It is narrow enough to be placed between vehicles in the typical city car park. It is a portable module that allows it to be used in an urban context for recharging cars. A van arrives at the destination, unloads the Fillee, enables charging and switches to recharging when the charge is complete.”

What about loose parts?

“Well, chemistry is the module, the loose parts are the non-chemical elements that make up the battery pack. These are the components that contribute to the current flow, enable the reading of signals, sensoristics and manage the optimisation of chemistry use. We could say that they are the real brains of the battery pack.”

To read the full story, click here or download the pdf