John Deere 13.6 liters approaching serial production

Three years have passed from the official presentation and John Deere 13.6 liters is approaching serial production. We saw it in the Deere’s natural habitat at Agritechnica, where we talked with Patrick Thil, Manager, OEM Sales, EAME, Asia & Australia. The key words? Power density, serviceability and a genuine industrial vocation. John Deere 13.6 liters. […]

Three years have passed from the official presentation and John Deere 13.6 liters is approaching serial production. We saw it in the Deere’s natural habitat at Agritechnica, where we talked with Patrick Thil, Manager, OEM Sales, EAME, Asia & Australia. The key words? Power density, serviceability and a genuine industrial vocation.

John Deere 13.6 liters. Let’s start from the draft

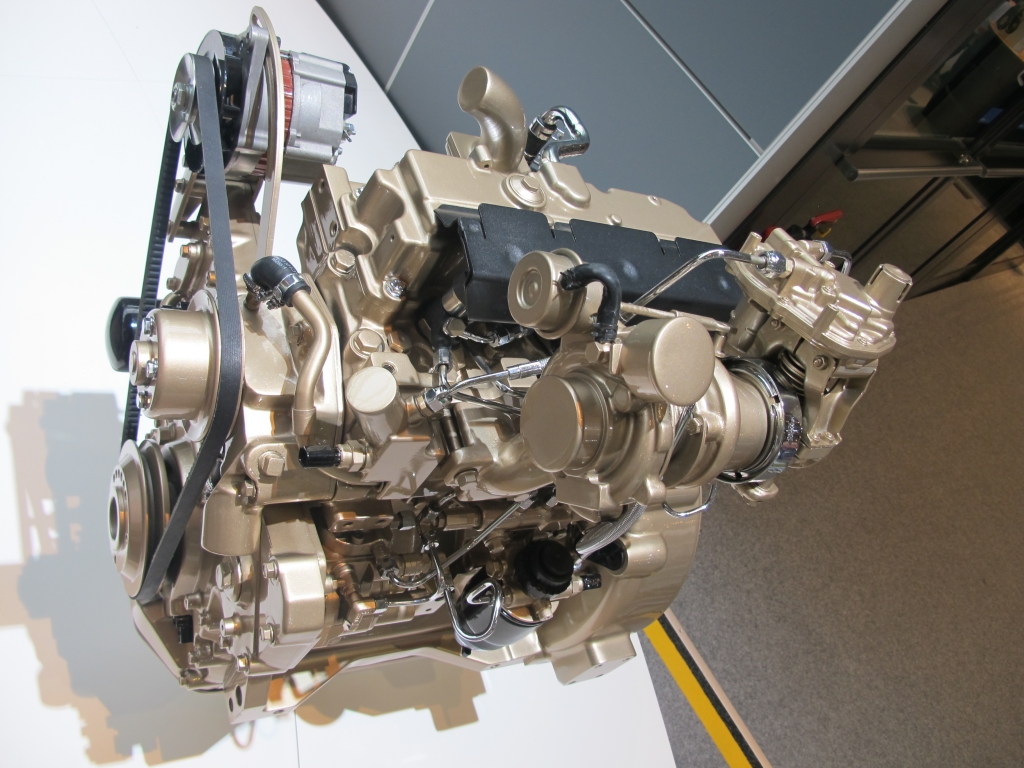

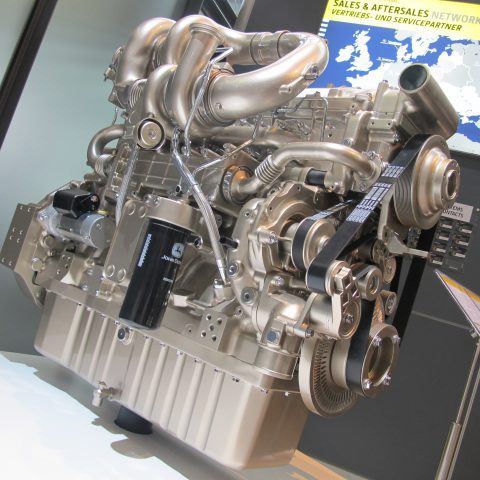

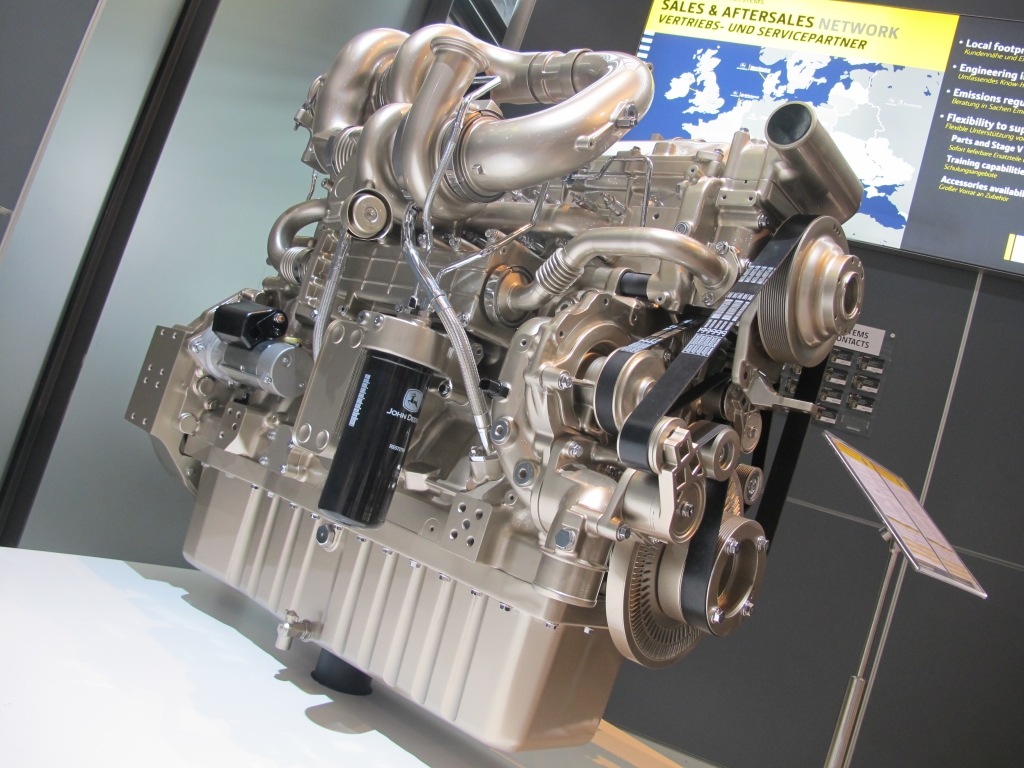

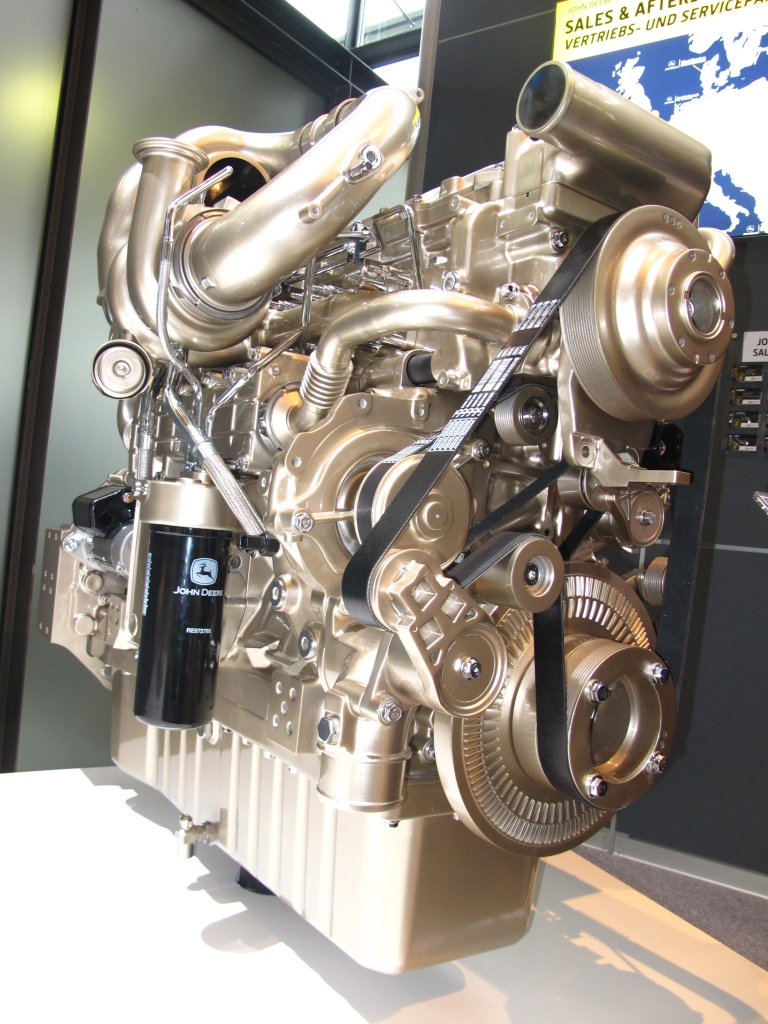

We increased the engine power, with the new 13.6 liters engine we can reach up to 510 kW, almost 700 hp. The engine block of the 13.6 liters has not dramatically changed, we modified the injection system to have higher fuel pressure and to achieve the right rating. Originally the unit injector was inside the engine and we put the common rail outside the engine cover. And we took the benefits of that to change a bit the head of the engine, reducing its size and integrating some automatic valve lash adjustments. We improved the noise level and serviceability as well. These are absolutely essential features for any OEM.

Has the turbocharger changed?

We have two versions, depending on the power level. The first one is equipped with the wastegate turbocharger; the second one fits the series turbochargers for the highest power. On the 13.5 engine we have a front gear system and we decided to move the gear at the rear of the new 13.6, just between the block and the flywheel housing, to reduce the size and the noise as well.

What about after-treatment? Starting from Stage IIB (or Interim Tier 4) John Deere diversified the technology for every displacement to join the specific needs of every application.

We have followed the same approach, developing a more compact system, to accomplish the goal of power density. We achieve some significant improvements: the 13.6 liters engine gained better performances, for instance 11 percent in torque, and 7 percent in fluid efficiency. To reduce the overall size of the engine, instead of two cannings we have designed an ‘all in one’ system. The production is going to start later on, this year.

JOHN DEERE AND LIEBHERR. THINKING BIG

And now, please persuade me to purchase this engine!

I need to know what kind of machine you have. Did you say… an open field tractor?

In any case, John Deere engines’ DNA doesn’t change, as they are engineered for heavy duty applications. The second point is to have performance without compromise. Fluid consumption is very, very important for us, even in Tier 4: when we adopted SCR and DPF, fluid consumption was from 2 to 4 percent compared to 7 or 8 percent of some competitors.

We’ve been using the DPF for many years and we manage perfectly the DPF’s regeneration. We collected more than one billion hours of working on the fields with particulate filter. So, the Stage V is really a ‘not event’ for us.