John Deere and electrification

John Deere and electrification. Here we’re going to accomplish our mission: talking to you about what is happening in the electrification process. Philippe Contault, JDPS Marketing Communication Manager, explained to us what electrification does it mean to John Deere. The last part of our conversation. John Deere and electrification. EMD-200-3 Electric Motor Drive has three […]

John Deere and electrification. Here we’re going to accomplish our mission: talking to you about what is happening in the electrification process. Philippe Contault, JDPS Marketing Communication Manager, explained to us what electrification does it mean to John Deere. The last part of our conversation.

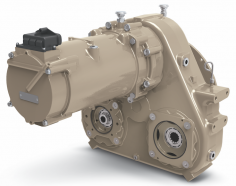

John Deere and electrification. EMD-200-3 Electric Motor Drive has three ratios. Is it possible to change the ratio even under load?

The EMD200-3 transmission is equipped with multiple wet disc clutches and offers a full powershift transition between gears.

With the EMD 200-3 the constant torque section is significantly reduced: what do you have in mind?

The EMD200-3 transmission delivers significant torque from a standstill to get the machine moving. The integration of John Deere power electronics controls allows a great deal of performance flexibility to match challenging operating conditions.

How does the EPD-200-2 Electric Pump Drive work and, in particular, how are the different pumps connected to it handled?

The Electric Pump Drive products offer the same performance, durability and flexibility of the Funk Pump Drive product line in an electrically-powered design. The Electric Pump Drive replaces the diesel engine with an electrically powered solution. When in operation, all pump pads operate at the same speed.

Describe us GPD-200-2 Generator Pump Drive

The GPD-200-2 offers a power generation rating up to 200 kW (268 hp) while simultaneously providing a max output speed of 3000 rpm and a max output torque of 881 Nm (650 lb-ft) for driving hydraulic pumps. It uses common mechanical system components. This generator pump drive can range from 100 to 400 kW in a single gearbox. In addition, it can achieve multiples of a single gearbox with parallel systems, meaning power management is no longer restricted to a single engine.

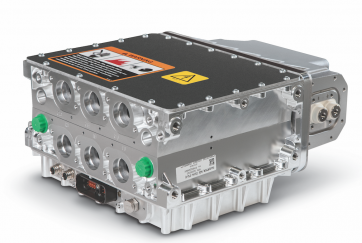

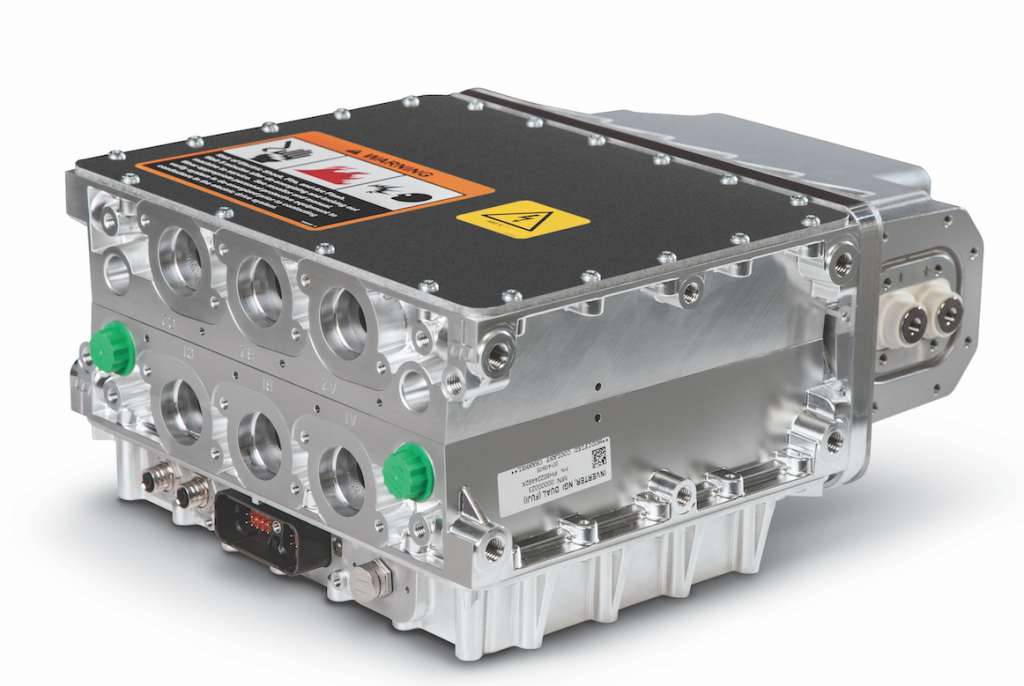

The Electronic Solutions PD series of Inverters is a family of inverters common to all your applications: what are the main features.

The PD series from John Deere Electronic Solutions (JDES) are high voltage, high power drivetrain inverters for 300 or 700V systems. They’re ideal for off-highway applications due to their rugged design and IP67 rating. JDES has taken a modular approach to the PD series inverters with factory mounted options, and they are compatible with a variety of motor manufacturers. The inverters utilize flexible software. JDES also provides training and technical support for its customers to ensure ease of integration. An advantage of pairing these JDES components with JDPS electric drive systems is that all of the motor integration work has already been completed and verified — saving that additional time for OEMs.

To conclude, let’s talk about the environment. In many sectors (e.g. the maritime one) the abandonment of hydraulics has allowed reducing the pollution due to oil leaks caused by pins. Have you thought of an environmental advantage in this sense also in the agricultural or construction sector?

Many off-highway markets are implementing electrification solutions. Exploring both completely electric and hybrid solutions as new technology becomes available could offer OEMs cost and efficiency benefits, as well as help meet environmental initiatives. There are specific market segments that drive off-highway electrification solutions because they are invested in using more efficient power generation methods and addressing emissions regulations, among other priorities. These segments include materials handling, rail transportation, and mining. In regard to agricultural and construction applications, there are multiple advantages to exploring electrification solutions. These include increased fuel efficiency, reduced noise and ease of operation. Certainly for inner-city construction sites, electric construction equipment helps customers meet carbon dioxide and noise pollution regulations, making electrification solutions a viable option. Regarding overall fuel efficiency, John Deere has experienced benefits to hybrid systems in its own applications. For example, the John Deere 644K hybrid wheel loader delivers up to 25% better average fuel efficiency than a conventional 644K wheel loader. In short, there are multiple factors that are currently driving the adoption of electrification solutions in other off-highway segments.