Machine learning and AI are crucial in today’s design environment. The tools developed by Ricardo

Ricardo developed some valuable tools based on machine learning and artificial intelligence in order to assist designers in managing the complexity dictated by the evolution of powertrain, since traditional design techniques are no longer sufficient. We spoke with two of Ricardo’s specialists, Peter Fussey and Farraen Mohd Azmin, about the impact of machine learning and artificial intelligence techniques on powertrain systems.

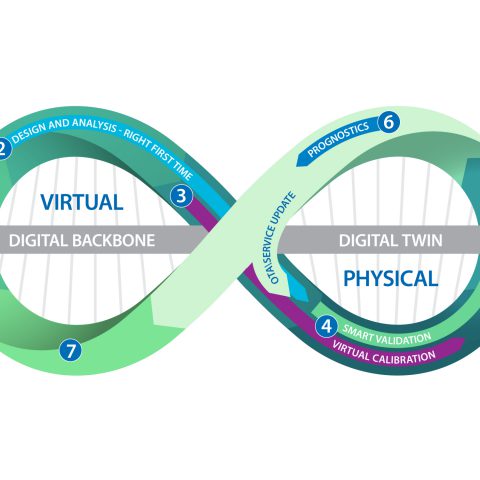

Ricardo developed some valuable tools based on machine learning and artificial intelligence in order to assist designers in managing the complexity dictated by the evolution of powertrain, since traditional design techniques are no longer sufficient. Indeed, the tools and techniques made possible by the advancement of digitalization can transform a product’s whole life cycle: from design to production, up to the testing and maintenance phases. This is true both for vehicles with traditional powertrain and for hybrid or electric vehicles; for on-road and off-highway.

We spoke with two of Ricardo’s specialists, Peter Fussey and Farraen Mohd Azmin, about the impact of machine learning and artificial intelligence techniques on powertrain systems. The full article is available on Powertrain July/August, page 40.

Ricardo: machine learning and AI predict the work an engineer might do

In today’s scenario, it is essential to find virtual alternatives to processes that have always taken place physically, while maximizing the efficiency of key steps such as calibration and validation. What is Ricardo’s goal, then? «To help companies improve not only their product development, but also their actual production», begins Peter Fussey. «The techniques and tools we have developed cut across the two areas. Automating processes bring tangible and measurable advantages in terms not only of time saving, but also of product quality and reliability. Not to mention the good impact that applying these concepts has on products’ life cycle».

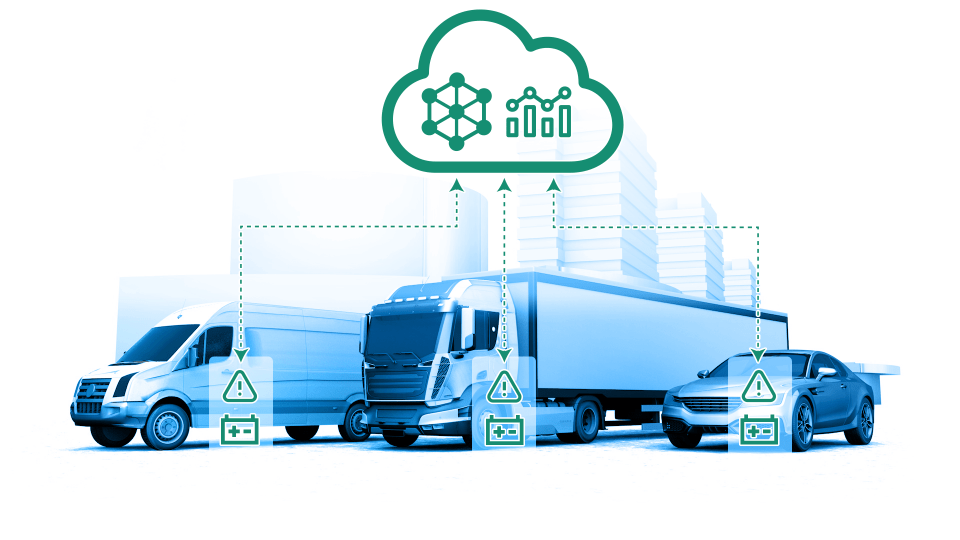

A promising scenario, also different when compared to traditional techniques. «Before, the development of a vehicle required a sequence of actions, tests and feedbacks and was highly dependent on the number of people working on the project. Now, by automating all this, algorithms as well as machine learning and artificial intelligence techniques are able to ‘read’ and predict the work an engineer might do, creating databases fed by real data and shared in the cloud», adds Farraen Mohd Azmin.

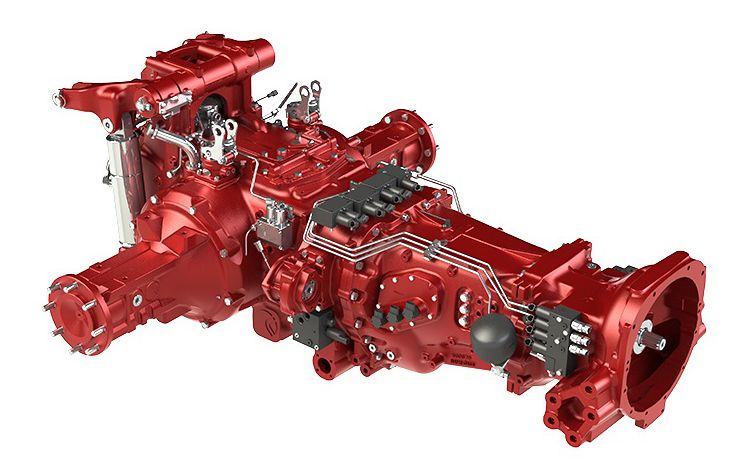

Managing complexity

One of the keywords is certainly ‘complexity’. «The hybridization of propulsion systems involves a previously unknown level of complexity. In fact, a hybrid system features an engine, automatic transmission, electric motor, batteries and battery management systems. Traditional tools are no longer effective given the increase in sophistication. In addition, unlike the physical environment, virtual models make it possible to simulate the most varied operating conditions of the vehicle, with important repercussions on the quality, reliability and robustness of the product. It’s a concept that comes from aerospace and can now be easily applied to automotive», explains Peter Fussey. «The application of machine learning and AI techniques could be even more decisive if we think about off-highway. In fact, these types of vehicles are not only required to transport people from one point to another, but they must also perform very specific tasks: not surprisingly, they are often interconnected machines, operating in fleets and familiar with data exchange and analysis. We see that even OEMs in off-highway are ready to embrace innovation and, especially after the pandemic outburst, are keener to consider electrification».

Potrebbe interessarti

Ricardo UK wins funding to improve efficiency of electric vehicles

The Efficient calibration toolset

«We have developed an actual toolset, so a set of tools that we call Efficient calibration toolset», explains Farraen Mohd Azmin, an expert in machine learning and directly involved in their development. «There is the Model Parameterization Tool (MPT) for defining maps, curves or parameter sets; the Ricardo Trace is a tool that allows users to automatically convert images extracted from a pdf into a Simulink model. Still, the Global optimization tool is designed for both diesel and gasoline or hybrid applications. We tried to develop these tools with user-friendly GUIs so that nearly any engineer can use them».