Volvo Penta D8 and D13 Stage V engines. Our interview with Kristian Vekas

An insight on Volvo Penta D8 and D13. We had been talking with Kristian Vekas, Product manager for genset engines at Volvo Penta, last March at MEE in Dubai, for the launch of the D16, the very first Stage V engine for gensets. And if that was – to quote the PM himself – the […]

An insight on Volvo Penta D8 and D13. We had been talking with Kristian Vekas, Product manager for genset engines at Volvo Penta, last March at MEE in Dubai, for the launch of the D16, the very first Stage V engine for gensets. And if that was – to quote the PM himself – the ‘tip of the iceberg’, now the tide has turned and we can see what was hiding under the surface of the water. Guiding us, once again, is Kristian Vekas, whom we met at the DPE in Rimini.

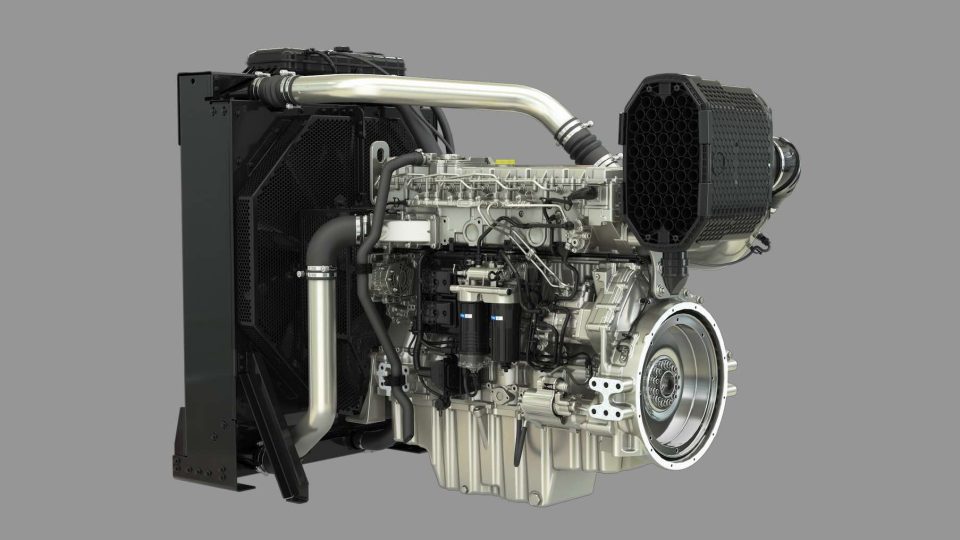

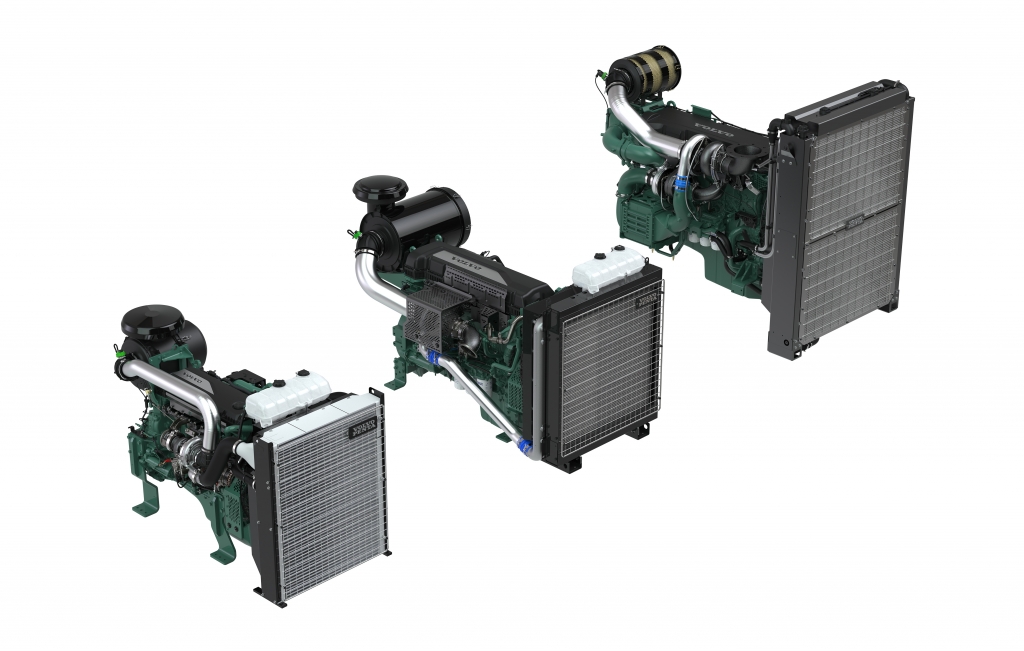

What are the main features of the new Volvo Penta D8 and D13 Stage V engines?

The Stage V range is developed with ease of installation, operation and maintenance in mind. Both are dual speed engines. The D13, switchable between 1,500 and 1,800 rpm, delivers up to 345 kWm. The D8, also switchable between 1,500 and 1,800 rpm, delivers up to 218 kWm. In both cases, simplified maintenance and lower fuel consumption are ensured to deliver an improved total cost of ownership compared to what we had before the Stage V, which implied a major challenge in aftertreatment. Not surprisingly, the SCR or DPF had never before been used in gensets. Instead, the current one is a complete system where the engine and after-treatment system fit together to work in full harmony.

D8. What’s new?

With the Stage V and more stringent emissions there’s a big challenge in after treatment. Things like SCR of DPF had never been used in genset applications.

To maximize robustness and reliability, we have selected a low complexity engine design. This has been possible thanks to high efficiency of the exhaust aftertreatment system, where the engine and aftertreatment system fit together to work as one complete system.

It means the engine doesn’t work without the after treatment and vice versa.

VOLVO PENTA AND THE STAGE V ENGINES IN HANNOVER

Talking about installation, is it available in different layouts?

For the D8 we offer a two-box solution: one part is the SCR and the other is the DPF. The reason why we have it is to be more flexible as for installation requirements. Since we have this, maintenance on the DPF is a lot easier: the filters, which have to be cleaned every now and then, can be changed more quickly. It is important to consider this when designing a genset. That’s something we have been talking about with our customers.

On the D13 we have a single box solution. The replacement of the DPF is very simple. It is enough to remove two clamps to extract and then replace the filter. The one-box solution for the D13 is due to the engine size.

What changes in terms of injection system?

We have introduced a fixed geometry turbo, for simplicity. The EGR was already on the Stage III, now we have uncooled EGR, that’s better from a cooling perspective. The heat management is on the engine, there’s no injector for fuel for the after treatment. It is a passive regeneration system. The fuel we burn is actually converted to energy, not wasted. Operational costs are more and more important for everyone and fuel is the biggest operational cost we have. We need more efficient systems.

We are using common rail both on the D8 and D13, this is also helping us to improve the fuel consumption compared to Stage IIIA.