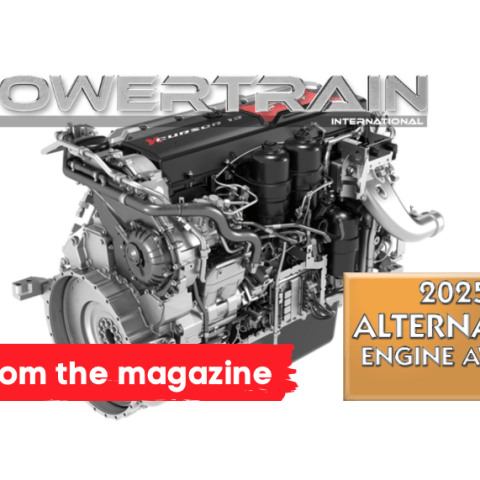

Alternative Engine Award: FPT under the sign of multi-fuel

An award that seems tailor-made for the XC13 by FPT Industrial. It is the Alternative Engine Award. The 13-litre has always been the star of the Cursor family and in the new X version it has been applied since its birth to IVECO trucks and, in the hydrogen version, has been on the ski slopes for three years with a snow groomer by Prinoth. Read the full story in the November issue of Powertrain International.

FPT Industrial’s XC13 won the first edition of the Alternative Engine Award. This matter-of-fact, powerful opening needs a bit of context. So let’s leap back to a few issues ago – and please forgive us for self-citation.

“POWERTRAIN has embraced the battery electric vehicle approach wholeheartedly, but with a strongly non-devotional attitude. The road that leads to liberation from car exhaust pollutants is paved with pitfalls and external variables. Why then stubbornly insist on ignoring the most efficient, well-proven technology ever used? We’re talking, obviously, about the internal combustion engine, which now proposes itself as its own alter ego.”

Electric vehicles sales declined sharply in Germany once government incentives dried up, and the supply chain has taken a worrying step backward (almost 15,000 Daimler workers risk being laid off, while Volkswagen’s need to save 10 billion Euros sparked shock announcements that the shutdown of domestic operations is being considered). This could speed up a rethinking of the very meaning of transition. Are these circumstances marking the redemption of ICEs?

The reappraisal of the hybrid solution may point to that. After becoming marginal following the Dieselgate, it is now offered in a combo with Otto cycle units; a recipe that’s probably scarcely suitable for long haulage on the road and totally unviable for industrial, stationary and marine applications. The combination of diesel, battery packs and electrical motors, freed from the lurking prejudice against the ICE, now testifies to the fact the so-called conventional approach to powertrains was redeemed and cleared of charges, making its comeback into engine compartments, under the bonnets and behind front grilles, encapsulated in gen-sets – places that, by the way, it had never left. Here the question arises. Why aim to something different than the Diesel of the Year? The award is nearing its first twentieth anniversary, is timelier than ever, and needs no beauty booster.

Well, the Alternative Engine Award is rooted in its being, indeed, an alternative.

Again, we’ll quote ourselves and repeat what we said a few months ago. “The engine block versatility certainly pays off well, being suited to a variety of fuels, starting with diesel. The design of an engine of this kind sure requires a common crankcase and almost all of its components. Major changes are found in its vital organs, such as injection and turbocharger. Sure, it needs to adapt to the Otto cycle – hence controlled ignition – for gaseous fuels. Plus, it must be compatible with burning hydrogen in its combustion chamber. Ideally, it should fit in with all of the following: diesel, HVO and biodiesel, CNG/LNG, H2 ICE and, possibly, include a battery pack as a back-up (PHEV/MHEV).

A set of features that could further be enriched with a multitasking personality: as in the case of conventional Diesel cycle engines, the possibility of fitting multiple applications would indeed be a “nice-to-have” skill to include in its resume.”

So the focus will inevitably be on all those engine platforms that were designed specifically to digest non-fossil fuels and eventually switch to hydrogen, but also prove to be nimble and flexible in terms of application range.

We liked how the engineering dept at JCB worked on the Ecomax – Diesel of the Year 2011 winner. The 4.8-litre was set up to run on hydrogen. Put to the test at quarry sites in UK, it handled it pretty well. Deutz, too, recently saw 100 gensets fitted with their TCG 7.8 H2 being commissioned at the Chinese State Innovation Zone ZGC, Beijing. Speaking of industrial applications, Bergen Engines, Caterpillar, Kohler (recently renamed Rehlko), Kubota, Liebherr Components, Perkins, Rolls-Royce Power Systems, Volvo Penta, Yanmar, VM Motori, Weichai are also venturing into this same territory, not to mention AVL and Dumarey among others. It’s Cummins that made the biggest step forwards, deploying all its resources, from road units (showcased at ACT Expo in Las Vegas as well as at the IAA), the specialist brand Accelera, down to Hydrogenics, whose expertise it incorporated back in 2019.

So why did the award go to FPT Industrial?

Down in the belly of XC13 you can feel an echo of the Cursor X. During FPT Tech Day at the Village in Turin, back in 2018, the Cursor X was presented to the press in what looked like a dark room. Resembling some kind of capsule with a futuristic, Star Trek-like look, its design is meant to summarize FPT Industrial’s vision: the module allows for the three different, independent engine units to be removable and interchangeable – for the sake of clarity, the engine can be extracted and replaced more or less in the same manner as a cell phone battery pack.

There are three interchangeable fuelling modes provided for by FPT’s far-sighted engineering creed. The Cursor X is made to work with the internal combustion of natural gas, hydrogen fuel cells or energy stored in a battery. No application is left out: commercial vehicles and trucks, city as well as mid- to long-haul buses, building site and earth moving machinery, tractors.

What FPT’s former CEO said back then sounds like a prophecy: “There can be no dominant energy form in the future. We advocate for the freedom to choose. FPT will maintain a pragmatic, multilevel approach.” And that’s again our starting point, because the XCursor 13 picked up the torch, achieving a goal that’s less distant in the future and more tangible. The engine block can adapt to diesel – including synthetic and biodiesel – and to methane, including in a bio version, and to hydrogen. We’ve dug up our recent interview with Andrea Abbà, Product Marketing Manager at FPT, which offers some background on the XC13 presented in Barcelona for IVECO’s Model Year 2024.

“Reducing fuel consumption was our North Star. To stick to this input, we revolutionized the engine starting from the very monobloc, whose material changed from cast iron to compacted graphite iron. Displacement per cylinder was our cornerstone, given that bore and stroke had remained unchanged, compared to the Cursor 13 (B&S 135×150 mm, editor’s note). We also implemented a new valve actuation system to maximize braking power, which allows vehicle engineers to avoid fitting a retarder on many applications. That’s an expedient that enables end customers to get a pretty considerable saving. This project enabled us to shed over 100 kg. I know we’re talking about a 44-ton truck, but this means the carrier will have 100 kg of extra payload.

We resized the crankshaft and used connecting rod journals and crankpin journals of a smaller diameter; plus, we added an electronically controlled dual flow ball bearing turbo, which optimizes air flow and thus also fuel consumption. We modified the common rail: pressure gets from 2,200 to 2,500 bar. We also made variations to the peak cylinder pressure, raising it to 250 bar. The engine consumes 7% less diesel compared to Model Year 2022 and as much as 9% less compared to the MY 2019, which is the baseline against which the impact set for 2025 is measured. The natural gas/biomethane version uses 8% less fuel compared to MY 2022 and 10% less compared to MY 2019.”

And that’s how IVECO’s S-Way truck showed up for the IAA Transportation in Hanover sporting the hydrogen-fuelled 13-litre engine. As for industrial units, we have to move to ski slopes to find it on the Leitwolf h2Motion by Prinoth (image above); it has been working nose to the grindstone in the snow groomer’s powertrain for a couple of years now. Hydrogen is stored in five tanks mounted on the back of the machine, allowing for indicatively over three hours of operation. We’ll have the time and opportunity to further explore the potential of XC13 engine platform.

To read the full article, click here or download the pdf.