Blue World Technologies: PEM and green methanol

Blue World Technologies has successfully tested a 200kW high-temperature PEM fuel cell module. The first pilot system is a 1MW system for onboard power production for one of A.P. Moller - Maersk’s large dual fuel-enabled methanol vessels. The installation on board is expected during the first half of 2026. Read the full story in the September issue of Powertrain International.

Proton exchange membrane fuel cells. The complex management of the energy transition applied to hydrogen also goes this way. It is not just a matter of infrastructure and incentives: the keyword of any technology upgrade in the energy world dramatically involves the principle of efficiency. In Scandinavian countries, the adoption of BEV and hydrogen systems is strongly encouraged, both by policy makers and the public. This is also the case in Denmark, where Blue World Technologies is based.

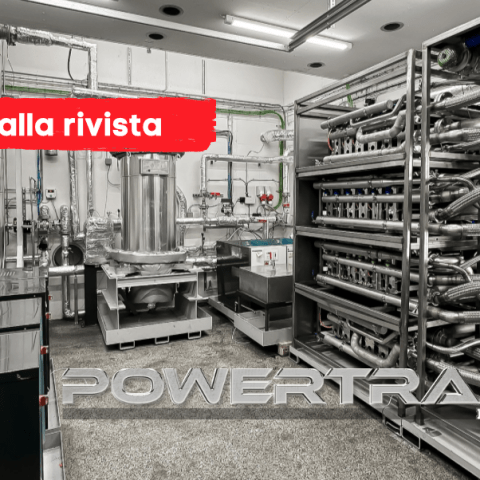

The announcement is official: testing of the world’s first 200kW high-temperature PEM fuel cell module was successful. The horizon is that of work boating, which, along with recreational boating above 80 feet, is wondering which way to go. That of ammonia, which would still only apply to Ro-Ro, LPG carriers, cargo boats, PSV, etc.? What is the best energy carrier: ethanol, methanol, bioLNG or what else? At Blue World Technologies, they are clear in their thinking, as shown by the statement of Dennis Naldal Jensen, Chief Technology Officer: “This is a major breakthrough within maritime decarbonisation and with the test of our 200kW system, we are proving that the HT PEM fuel cell technology has the potential of being one of the key technologies to decarbonise the hard-to-abate sectors. During the test period, we successfully validated our system set-up with the methanol fuel processor, the series connection of the fuel cell stacks, as well as the balance of plant components surrounding the fuel cells.”

The first pilot system is a 1MW system for onboard power production. The system will be installed on one of A.P. Moller – Maersk’s large dual fuel-enabled methanol vessels and the installation on board is expected during the first half of 2026. “Maersk is the global frontrunner when it comes to maritime decarbonisation, and we are very pleased with the collaboration on the first 1MW pilot and we are very much looking forward to getting the system out sailing,” says Anders Korsgaard, Co-founder and Chief Executive Officer at Blue World Technologies.

What are the main coordinates followed by the Danish Company in this project? The system is a scalable configuration, firstly aiming to replace conventional fossil-based gensets, but later also provided as large multi-megawatt fuel cell-based propulsion systems. Thoughts at the design stage were aimed at ease of installation on board. The approach was therefore modular, allowing for fuel cell power systems as containerised solutions on deck or integrated on the ship.

With an efficiency of up to 55% when reaching commercial stage, the system typically provides a fuel saving of 20-30%. The system, that is based on high-temperature PEM fuel cell technology (HT PEM), provide high-grade waste heat of 150°C. Finally, the fallout on environmental impact.

When powered by renewable methanol, the system has a net-zero operation. The fuel cell system is ready for carbon capture, allowing for CO2 to be recycled or storage. Blue World will initially supply systems for auxiliary power and expects that their maritime system will reach a commercial level in 2027. Eventually, the company will proceed to supply multi-megawatt propulsion systems for global shipping.

We turn it over to Alex Smout, Investment Director at Maersk Growth, for final thoughts, regarding the investment: “The maritime industry needs multiple new technologies and pathways to reach its net-zero targets, and high-temperature PEM fuel cell technology is very promising in finding a balance between the high electrical efficiency, size, and load adjustment. This is a great example of how we can support innovation through both investment and partnership.”

To read the full article, click here or download the pdf.