Comer Industries: electrifying agriculture

At Agritechnica 2023 Comer Industries presented a selection of its latest solutions for tractors, implements and harvesting machines developed to provide answers to its customers in the agricultural sector. We asked some questions to Paolo Negri, General Manager e-comer, and Jacopo Spaggiari, Business Development Manager, Sales & Marketing. Read the full story in the March issue of Powertrain International.

At Agritechnica 2023 Comer Industries presented a selection of its latest solutions for tractors, implements and harvesting machines developed to provide answers to its customers in the agricultural sector. We asked some questions to Paolo Negri, General Manager e-comer, and Jacopo Spaggiari, Business Development Manager, Sales & Marketing.

How is the integration with Walterscheid proceeding, starting from the PWE480 cardan shaft?

Negri: “The integration is progressing well, it hasn’t been easy, but now we have reached a good level of clarity on all points, also with regard to the cardan shaft that we present here, which is the first product created, and represents a mix of the best of the two brands.” The PWE480 shaft features an improved hexalobate profile of the tube, which guarantees perfect operation and higher performance for high-speed applications, satisfying the demanding market requirements typical of round balers. The new shaft also incorporates a new overrunning device embedded directly in the cut-out clutch: this innovation guarantees a more compact design.

An overview of the updates relating to the cardan shafts that you are presenting at this fair.

Spaggiari: “We decided to give some space to the world of tractors by presenting two innovations regarding the cardan shafts with the two different brands, Walterscheid and Mechanics Driveshafts. The first novelty is represented by the new size of the 7C family under the Mechanics Driveshafts brand, dedicated to high-power tractors (above 250 hp). It is a cardan shaft (the 7C) which has some characteristics that make it particularly interesting because we have equipped it with a service-free cross kit.” The new 7C-FS is a longitudinal shaft that transfers propulsive power from the main central transmission to the front axle, suitable for the most demanding applications for heavy tractors: this high-performance cardan shaft is capable of transmitting up to 10,500 Nm, is suitable for the size of category 4 machines, it can accommodate a maximum intermittent articulation angle of 25° and is equipped with the “Next Generation” cross kit.

Spaggiari: “The second product that we are introducing is the new longitudinal cardan shafts series for the smaller tractor categories, below 100-150 horsepower. The 687.18 Cardan Shaft is on exhibit, transmitting up to 3,500 Nm, and representing most of the key features of this new range, like flanged version, service free length compensation, modular and flexible design.”

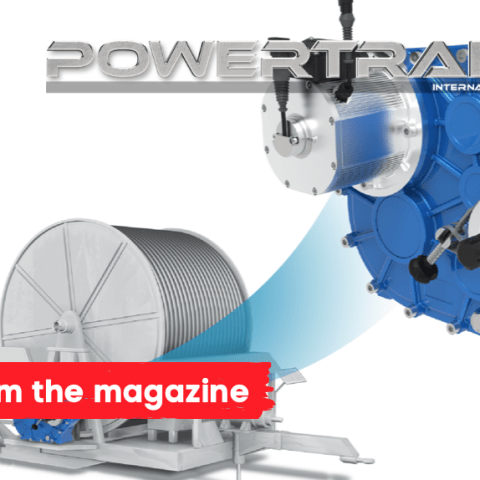

The latest electric innovation from e-comer exhibited at Agritechnica, the new WD220 Series, is an “all-in-one” integrated electric transmission: ideal for the constantly growing sector of self-driving agricultural machines (also called AgBot) or for harvesting and multipurpose machines. This new product combines a two-stage planetary gearbox with an internal permanent magnet motor from the e-comer SMAC series, capable of delivering high torque and meeting the long-life performance expectations of the machine, as tested on some machines already operating in the field; it is the perfect electric, waterproof and interchangeable alternative to hydraulically operated gearboxes.

Regarding this new series, Negri comments: “Obviously integrating the electric motor inside the mechanical part is not always easy but it’s beneficial for reducing overall dimensions and increasing the efficiency. The impact of this technology is naturally very high.” The spotlight in this edition was focused above all on the synergy and co-design between Comer Industries and the e-comer R&D department with the preview of the e-742 transmission dedicated to hose reel irrigators with motor pump or hydraulic turbine.

Which types of pumps is the e-742 transmission associated with exactly? You are talking about a 10% reduction in consumption due to greater efficiency. Technically, how did you achieve this result?

Spaggiari: “The e-742 transmission is designed to equip hose reel irrigators with integrated motor pump or water turbine and it is engineered to optimize all irrigation phases, from hose-rewinding to remote speed management, as well as automatic decoupling of the power transmission, therefore it aims to combine the operator’s safety with a reduction in the operator’s engagement times because with the use of the electric motor we have eliminated the need of gear shifting, thus significantly reducing the direct intervention of the operator, in other words we have been working on the overall improvement of the transmission efficiency and consequently on the efficiency of all field operations.”

To read the full story click here or download the pdf.