Comparisons: 5 to 5.2 liters

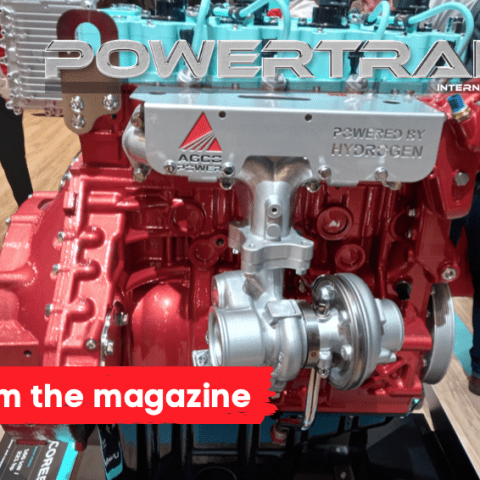

AGCO Power’s Core family expands. The 1.25-liter cylinder displacement also applies to 4-cylinder Diesel engine and throws down the gauntlet in this micro-segment. Veterans mtu and Volvo Penta are joined by the Finns, Deutz, Kubota and Isuzu. Read the full article in the March issue of Powertrain International.

It was 2019, at Bauma Munich. Kubota was crowned Diesel of the Year with its V5009; a 5 litre that gained a following. Indeed, there are six 4 cylinders all lined up for a comparison on these pages. So, let’s start with the newest entry, the Core50 by AGCO Power. It completes the bottom section of the newly introduced Core range that’s recoded the language of AGCO Power Group’s engine department. A network that got a fresh boost from TAFE (Tractors and Farm Equipment limited) becoming a significant shareholder in the Corporation. The Indian group is the third largest agricultural OEM in the world.

There is no shortage of synergies, then, as confirmed to us by Massimo Ribaldone, TAFE’s CTO and Business Development President. “Today, India’s industrial base provides for manufacturing at a reasonable cost with proven technologies; yet, quality comes at a price and costs also stem from the need to provide a centralized European sales and marketing structure to support importers across different countries. Ours is, therefore, a global range with a shared platform for all markets and scalable upgrades based on the relevant region. 75hp Stage V engines are manufactured in India based on the Tier 4 Final units equipping the Massey Fergusons”.

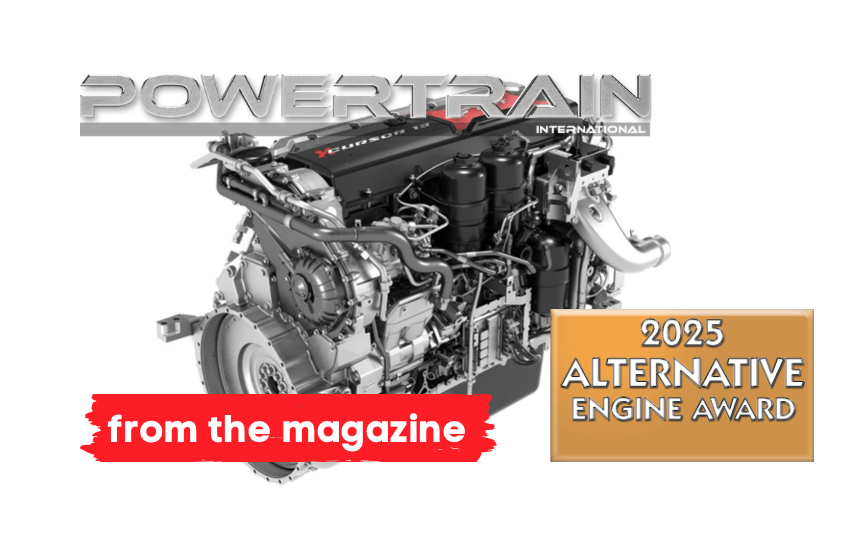

Spearheading the Finnish renewal is Core75. Announced in a low-speed mode embodiment, it was followed by a medium speed one shortly after. We can’t, then, rule out that the 5 litre will be available in a wider range of cylinder number options depending on captive needs and its impact on the free market. Cylinder displacement is modular and the engine block was designed with the same engineering features; we will, therefore, repeat what we already said in May’s comparison, with all due exceptions. Under the lens, the 1.25L cylinder displacement in the 6-cylinder configuration; an engine block – as we said back then – that does not make it to the podium based on the comparison’s indices, and yet stands out for torque, reaching second place behind mtu and climbing the ranking thanks to torque at max power. Compared to the three top positions, it pays a toll in power curve comparison – 20% less, precisely, compared to Friedrichshafen’s fastest horse, the 6R1000. A conservative choice embodied in piston speed, stuck at only 7.5 metres per second. After all, the first application of this 1.25 dm3 single cylinder was Fendt 728 Vario, winner of Tractor of the Year 2023. But there’s more to this engine’s architecture than just thermodynamic performance. Quoting AGCO Power Marketing Manager Tommi Puomisto we approached at Bauma Munich: “It’s a fact that the technology on the market is not 100% ready for carbon neutrality, but we need to take all steps to get it closer to it. Specific consumption is 188 g/kwh – we’ll be happy to compare it to that of any other competitor with publicly accessible technical datasheets. Specific consumption values are often higher than 200 g/kwh”.

Are these similarities also found in performance? Specific power moves from 29.6 kW per litre to 32.8. Specific torque is slightly lower and yet it becomes best in class when compared to the five equally sized competitors. Head-to-head with its big brother, the Core50 dashes forward tanks to torque reserve and it knocks out the contenders in the max power curves comparison. Out of 950 Nm recorded at peak power – an asset that allows AGCO to flank Deutz at the top – no less than 921 are still available as power reaches the peak value, right when one would expect the curve to start declining; instead, it stays basically stable from 1200 to 1900 rpm.

AGCO Power too has chosen to remove the recirculation valve so as to minimize heat, make the radiator more compact and avoid a negative impact on specific fuel consumption.

The Diesel Index is instead rewarding for Deutz’s 5.2L, the most muscular of the group. Size-wise the AGCO gets close to the approach of the 5.2; since the Cologne engine gained a millimetre in bore – from 109 to 110 – and two in stroke (from 134 to 136), the 5.2 litre was among the first to give up on the EGR, one of the German mechanical engineering dogmas. That’s an engine that has a lot to say to the market of mobile working machinery, including when considering mean effective pressure, leaving room for action on the piston to achieve overall efficiency.

We were speaking about Kubota, that went past the 110kW pillars of Hercules right with its 5 litre. Looking at the Japanese 4 cylinder one gets impressed with its extremely compact size. The Osaka-based engine maker pushed hard on MEP – contrary to what’s customary for Kubota, for which the monobloc’s robustness comes prior to any excess within the combustion chamber. With 17.4 bar, the 1.250 litre cylinder displacement can support performance and boost specific curves without “pressuring” the piston too much. As mentioned, rpms are in line with those of its talented contenders and piston linear speed well set below the fatidic value of 10 metres per second.

As pointed out during the V5009 awarding ceremony at Bauma Munich, “since the middle of the last decade, and increasingly more often as of III B, the true driving force of internal combustion engines have been emissions standards. No manufacturer was able to find an alternative to the DPF – SCR combo. EGR was the only distinctive element. Kubota’s strategy – improving on the after-treatment system and combustion parameters – was a winning one”. Isuzu now moved this unit into the Tier 4 Final/Stage V territory, but without altering its mood. Low stress, no gambling with performance characterizes this engine that’s basically designed to work at construction sites.

Rolls-Royce Power Systems and Volvo Penta are placing their bets on two thoroughbreds, widely tested and reliable. The mtu 1000 Series confirms its sophisticated architecture that shows painstaking care for boosting as well as fuel supply. The 4R becomes a party of four: 115, 129, 150 and 170 kW at 2200 rpm. This series, up to series 1500, will be marketed by Deutz, while waiting for 2028 when the agreement with Daimler Truck is set to enter into force. The heavy-duty engines will keep being built by Daimler Truck at the Mercedes-Benz plant in Mannheim and sent to Deutz for the final assembly, while the medium speed range will be manufactured entirely in Cologne.

The Swedes, too, are taking sophisticated solutions pretty seriously. The variable geometry turbo is a legacy of research into the on road heavy duty domain; the EMS – Engine Management System – control unit governs the system and can be controlled remotely.

Fine particles are taken care of through the high temperature within the chamber. The unavoidable nitrous oxides trade-off is handled by the EGR-SCR duo, upstream and downstream of the combustion stage, respectively. The aftertreatment system then gets shorter and freed from the burden of regeneration.

To read the full article click here or download the pdf