Cannes Yachting Festival. 42nd edition

Cannes 2019: MTU, MAN, Nanni Cannes 2019, for MTU the patht to take is towards hybrid solutions. The trajectory designed by Friedrichshafen is the one of the solution provider, and the diesel-electric architecture allows to follow the regulations while also answering the needs of the marine sector: besides the reduction of pollutants from the propeller, […]

Cannes 2019: MTU, MAN, Nanni

Cannes 2019, for MTU the patht to take is towards hybrid solutions. The trajectory designed by Friedrichshafen is the one of the solution provider, and the diesel-electric architecture allows to follow the regulations while also answering the needs of the marine sector: besides the reduction of pollutants from the propeller, the objective is to improve the efficiency of the system and reduce noise on board. Sunseeker has been the first shipyard to choose the Rolls-Royce Power Systems serialized hybrid (the official announcement at the last Boot Show in Düsseldorf).

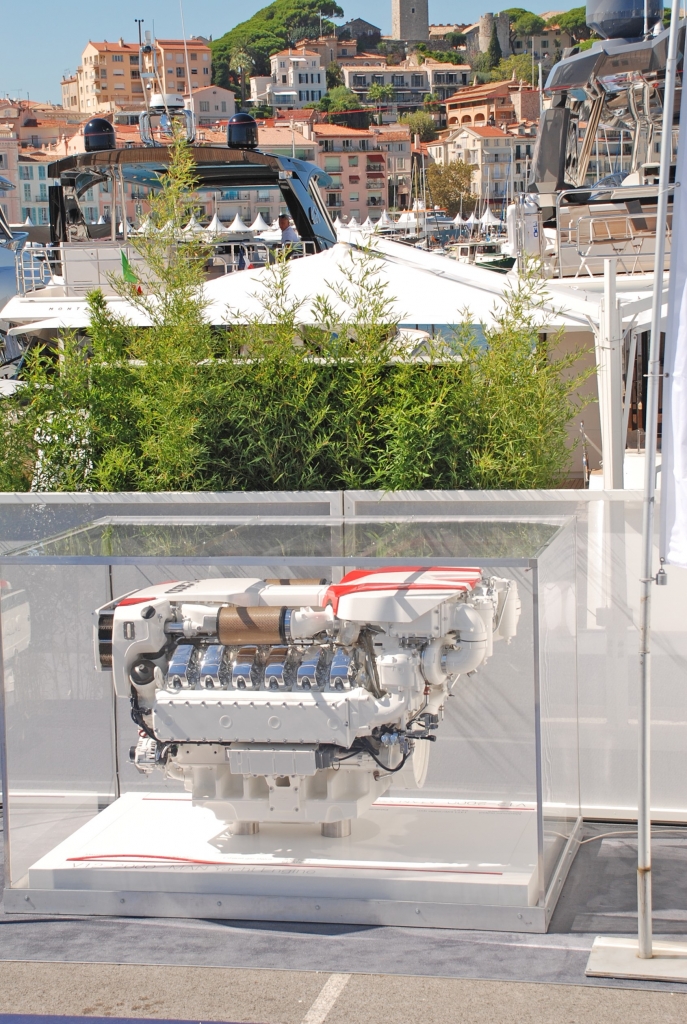

MAN brought the V12 2000 at the Monte Carlo Yachts booth. The best in class also found its place at the Monfalcone shipyard, after the AB 100. The younger brother made its regular appereance at the lion’s booth: a V engine with 8 cylinders, the famous two-liter cylinder displacement (BxS 128 x 157 mm), with an output of 956 kilowatts.

Nanni Diesel was also present with last year’s format, with the complete Scania Platinum series: in addition to the 6-cylinder there was also the 16-liter N16.10100CR3, with its 662 kilowatt output at 2,300 rpm.

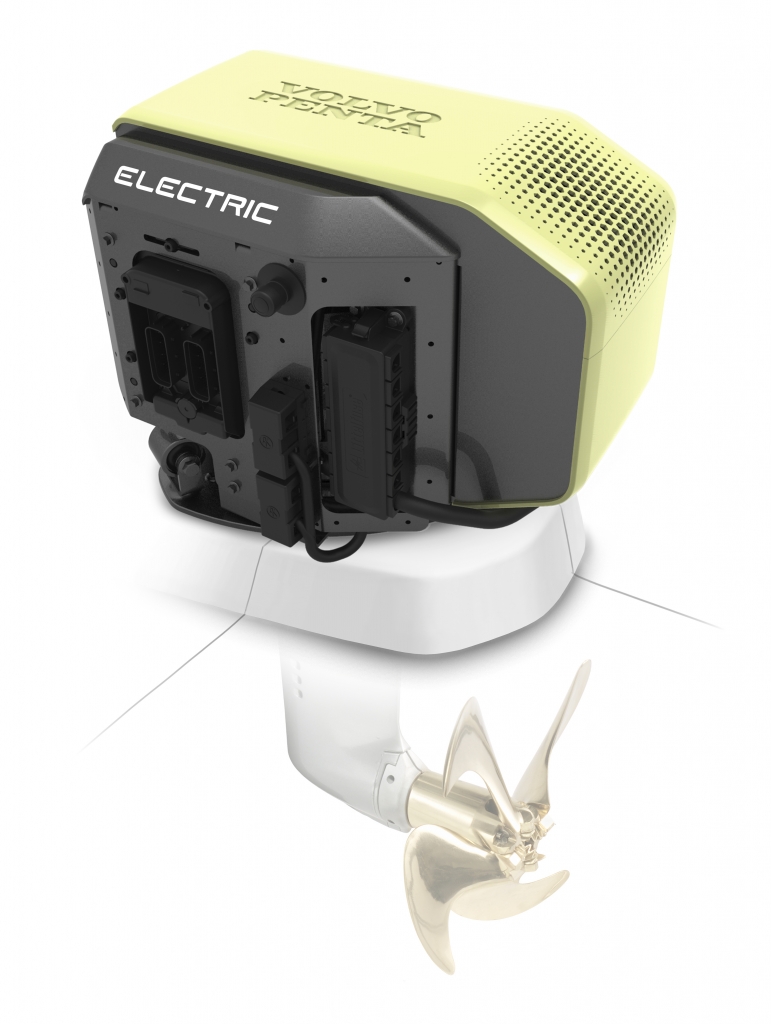

Volvo Penta brings electrification to the water

At Port Canto in Cannes we boarded one of the previews of the Volvo Penta electrification program: after the excavator at Bauma 2019, it is the turn of the Lucia 40 catamaran, coming from the Fountaine Pajot shipyard. In the engine compartment we find the D1-20. The transplant was carried out with no “rejection”: the 40 kilowatts of total output, coming from the contribution of 20 kW of each engine, make it possible to replicate the performance of the endothermic engine.

Anna Lindgren, Director of Marine Leisure Product Management, points out that the impact of this change goes far beyond the simple ecological impact: maneuverability is the key, also due to the immediate availability of electrical torque. Another plus is the silence: no mechanical echo during navigation and the possibility of muzzling peripherals during docking.

The data coming from the electric group speak of a torque of 27 Nm at 5 knots and 17 Nm at 6 knots, for a maximum speed of 8 knots, with an hour of autonomy, which rises to three hours at a speed of 6 knots. The supervision is in the hands of the electronic control EVC 2. Combined with a single interface for electric propulsion, a system adapted to the needs of power supply and hull (which with the endothermic engine does not usually have such control). The groups on board deliver 7.2 kilowatts each and during navigation they are able to recharge the two 20 kW batteries, which supply energy for the fridge, air conditioning and other peripherals up to 12 hours.

Peter Granqvist, Chief Technology Officer, also clarified the synergy with the construction site: «Having identified user profiles, we can more accurately predict aspects of the system, like the battery lifetime, which in turn provides increased peace-of-mind to a user or captain».