Hug Engineering tackles the issue of ATS: new catalyst with improved chemical performances

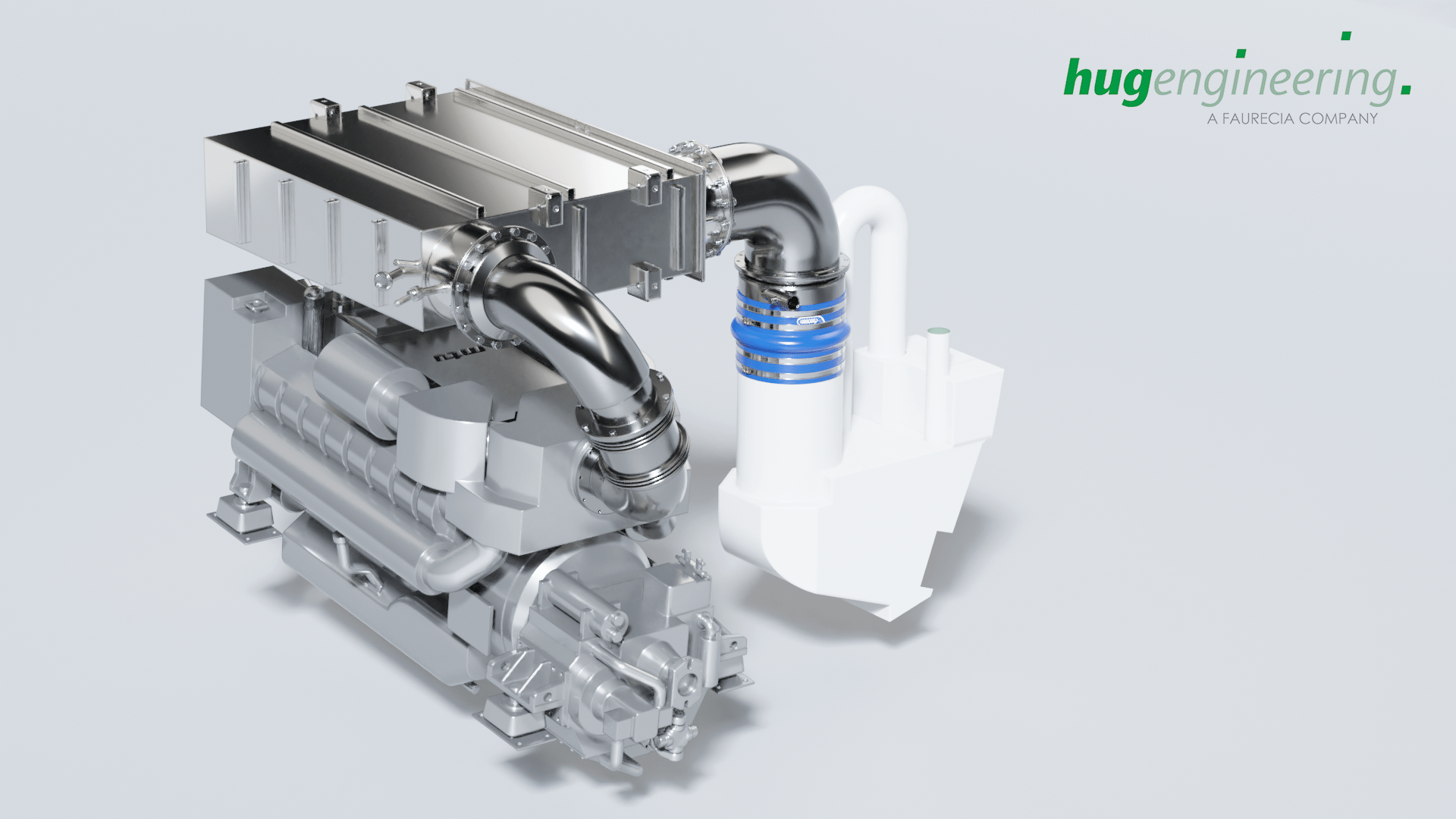

In 2020, Hug Engineeering developed a new catalyst which enables chemical performances that, given the same volume, are higher than 50 per cent. This is indeed a significant step forward towards a better ATS integration and switchability.

In 2020, Hug Engineering developed a new catalyst which enables chemical performances that, given the same volume, are higher than 50 per cent. This is indeed a significant step forward towards a better ATS integration and switchability. For the latest issue of Diesel International, we asked the Swiss company to start right from the premises.

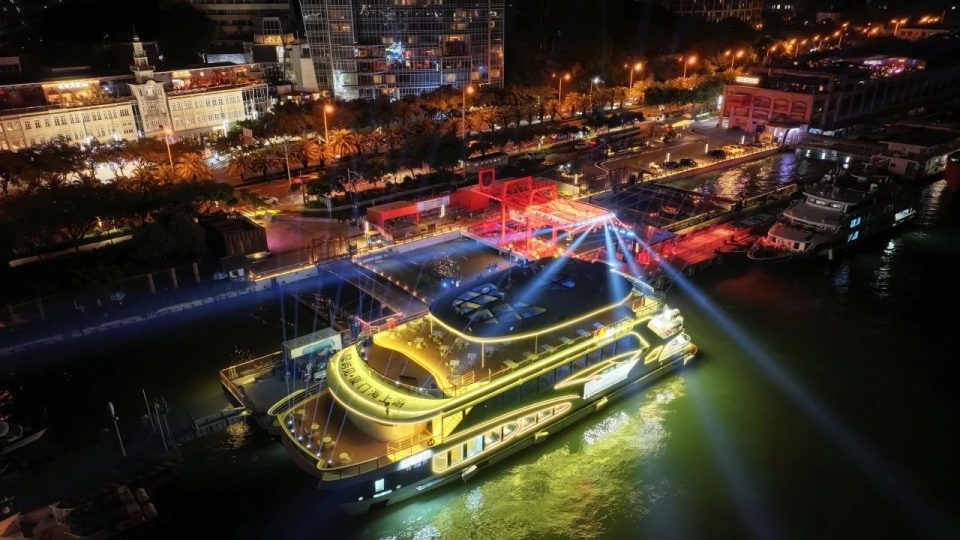

«Since 2014, we have worked to diversify our client base: in the Italian shipyard industry alone, at Fincantieri Yachts and Azimut Benetti, we have established a partnership with, among others, Tecnomar, NCA and San Lorenzo. At the moment, the SCR is sufficient, but the demand trend goes towards an ATS integrating SCR and DPF. The IMO Tier III has been mandatory for vessels over 500 gt in the US since 2016, with a waiver below this tonnage. Its suspension has been applied until January 2021. Now, there are no more excuses or loopholes».

Hug Engineeering and the catalyst: the difference compared to automotive

Let’s clarify the differences between an automotive and an industrial SCR. «An industrial SCR has a number of prerogatives: it is not made of a metallic material but of a ceramic extruded material; back pressures are very low; there is a ‘transparency’ requirement with respect to the original Tier II engine emission limits, its mixing and uniformity of dosages; and the urea injection must be assisted by compressed air. The opposite is true for the automotive industry: it must be integrated into the engine; it is subject to high back pressures; it is made of metallic materials to endure the cycle of use. The mechanical resistance is key, since it is a device which is subject to moving parts stresses, such as with cars, especially when driving on highly challenging road surfaces. Automotive follows standardisation criteria, whereas project adaptability is fundamental in the industrial sector, where all products are customised».

The shipowners’ sensitivity

In the absence of draconian constraints, the leverage comes from the shipowners’ sensitivity. «In the last two years, in particular, we have seen a strong interest in an aftertreatment solution that is sustainable in terms of weight, size, performance and reliability, and also takes care of all those aspects which are neglected by the current regulations, such as ammonia slip. We also consider the request for ‘comfort’ coming from yacht users: the ammonia odour threshold must not be exceeded, and shipowners wish to sail all over the world without leaving a trail of soot, neither in the air nor in the water, as happens today».

The NOx are eliminated by ammonia

At this point, we’d better explain the innovation rate of the ATS for yachting, recently realized by Hug. «We have decided to raise the catalyst bar from a chemical-catalytic point of view. In 2020, we developed a new catalyst which enables chemical performances that, at the same volume, are higher than 50 percent. Therefore, we have increased the degree of conversion. In few words, the NOx are eliminated by ammonia, which cannot be stored on board. The solution is to produce ammonia from technical urea. Urea goes from a liquid state to a gaseous state, then converts to ammonia, triggering the reaction in the catalyst. Ammonia and NOx residues must be eliminated. Depending on the efficiency, these residues are between 1 and 5 per cent. What is the competitive advantage of our system over the typical formulas adopted by the other engineers? Generally, the latter provide finer meshes and create back pressures that require a constant use of the SCR, regardless of the conditions of use and latitude. In case of an ocean crossing, considerable urea storage is required. We are also talking about three to four thousand litres of additional urea on board».

This is where the famous ‘switchability’ comes into play, allowing the system to be switched off and on as required. This means having as much urea on board as is needed to cross American territorial waters and drop anchor in Fort Lauderdale, Tampa or Miami. Otherwise, the engine runs peacefully without downstream aids, including technical urea.