MAN B&W and the first mega-container vessel retrofit to LNG

MAN Energy Solutions has signed a contract for the conversion of a 15,000 TEU container vessel to dual-fuel operation The container vessel MV Sajir is owned by Hapag-Lloyd, one of the world’s leading liner shipping companies, and normally serves a route from Asia to northern Europe via the Suez canal. The pilot project will entail […]

MAN Energy Solutions has signed a contract for the conversion of a 15,000 TEU container vessel to dual-fuel operation

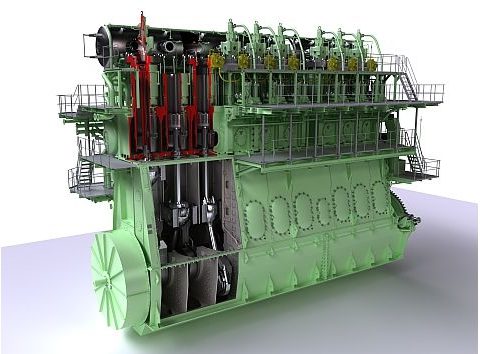

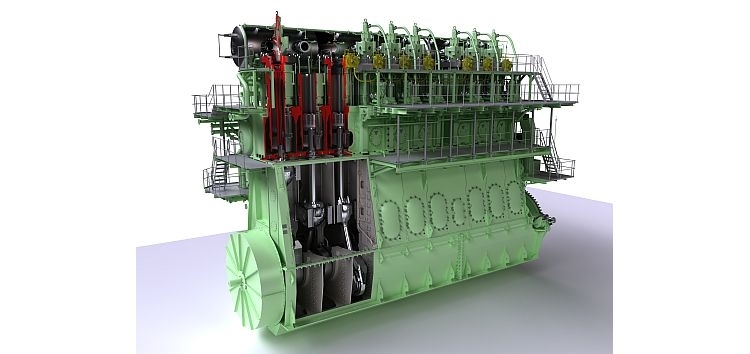

The container vessel MV Sajir is owned by Hapag-Lloyd, one of the world’s leading liner shipping companies, and normally serves a route from Asia to northern Europe via the Suez canal. The pilot project will entail the conversion of an existing, HFO-burning MAN B&W 9S90ME-C engine to a dual-fuel MAN B&W ME-GI (-Gas Injection) prime mover capable of running on HFO and LNG. The retrofit will be done at the Chinese Hudong/HRDD shipyard.

Wayne Jones, Chief Sales Officer and Member of the Executive Board at MAN Energy Solutions, said: «We are seeing great interest in this project from the industry as a whole. This is an excellent showcase for the conversion of a mega-container vessel to LNG and the potential benefits for the market is huge. With this announcement, MAN Energy Solutions is once again at the forefront of technology with our ability to execute LNG conversions for both four-stroke and two-stroke engines».

The emission savings for MAN B&W two-stroke engines are significant when converting an existing HFO engine to LNG. Using LNG in the shipping industry could reduce CO2 emissions by 15 to 20 percent and sulphur dioxide and particulate matter by more than 90 percent.

Richard von Berlepsch, Managing Director of Fleet Management at Hapag-Lloyd said: «By converting the ‘Sajir’, we will be the first shipping company to retrofit a container ship of this size to LNG propulsion. With this unprecedented pilot, we hope to learn for the future and to pave the way for large ships to be retrofitted to use this alternative fuel».

The Hapag-Lloyd pilot project is scheduled to take place in 2020 when the five-year old vessel will spend 90 days in dock.

MAN ENGINES AT BAUMA MUNICH 2019

MAN’s strategy seems clear

Wayne Jones added: «MAN Energy Solutions’ strategy is to provide complete, fully integrated solutions. Accordingly, MAN Cryo will install an entire gas system to supply gas to the main, as well as to the auxiliary engines, including a MAN Energy Solutions 300 bar high pressure Pump Vaporizer System (PVU)». MAN Energy Solutions took over fuel-gas dedicated company Cryo AB in 2015 and fully integrated it into its business. Under the brand MAN Cryo, the company offers systems for the storage, distribution and handling of liquefied gases.

In respect to four-stroke, Jones was referring to the 2017 conversion of Wessels Reederei’s ‘Wes Amelie’, a 1,036-teu container ship that was originally fitted with an MAN 8L48/60B diesel engine. Upon conversion to a dual-fuel MAN 51/60DF unit, the ‘Wes Amelie’ reported significantly changed emissions. The vessel now meets both the Tier II and Tier III emission requirements set by the International Maritime Organisation (IMO).

The maritime energy transition

The retrofitting of the MAN B&W 9S90ME-C engine to ME-GI dual-fuel running is part of the ‘Maritime Energy Transition’, an umbrella term that covers all MAN Energy Solutions activities in regard to supporting a climate-neutral shipping industry.

The term stems from the German expression ‘Energiewende’ and encapsulates MAN Energy Solutions’ call to action to reduce emissions and establish natural gases as the fuels of choice in global shipping. It promotes a global ‘turn to gas’, driven by the IMO, and a common approach by the shipping industry and politics to invest in infrastructure development and retrofits.