MAN SCR? It’s a pleasure… (application)

MAN SCR. On the water too… MAN SCR. In Nuremberg they are very familiar with after-treatment, having started with trucks to apply this expertise to off-road and recently marine applications. Here is a summary of the technical characteristics of the SCR of the Lion for boating (here you can find the interpretation of the MAN […]

MAN SCR. On the water too…

MAN SCR. In Nuremberg they are very familiar with after-treatment, having started with trucks to apply this expertise to off-road and recently marine applications. Here is a summary of the technical characteristics of the SCR of the Lion for boating (here you can find the interpretation of the MAN cousins – MAN Energy Solutions – for commercial boats).

Your solution provides a single module for SCR, DOC and DPF (the so-called ‘all-in-one’), two separate modules or do you have a flexible application? How does the electronic control unit work? Could you describe the sensors system in brief?

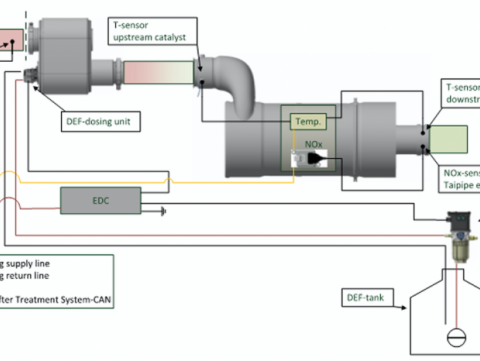

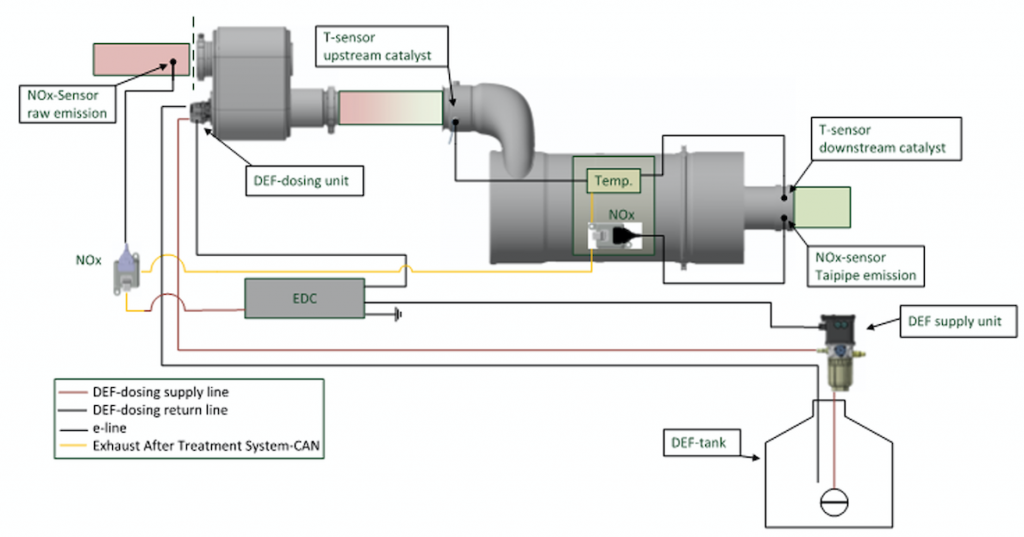

At the moment (March 2020), MAN Engines offers for Marine applications in IMO Tier III engines > 300 kW. These MAN engines are equipped with the modular exhaust after treatment system (EAT) of MAN Engines, which allows a great variety of different installation options due to its modularity and flexibility. The main parts of this EAT for engines >300 kW is the selective catalytic reduction (SCR) after-treatment system and a urea solution (AdBlue©) injection system for NOxemissions control. A DOC or DPF is not needed. The SCR system contains a mixing unit, where the urea solution is added to the exhaust gas. After that the exhaust gas with the vaporized urea flows through the SCR catalyst where the NOxemissions are reduced. The SCR process uses ammonia (NH3), which is built of the urea solution, to reduce nitrogen oxides (NOx) to nitrogen (N2), water vapor (H2O), and carbon dioxide (CO2).The substrate of the catalyst is coated with a vanadium-based material, which triggers these chemical reactions.The control logic with NOx-sensors upstream and downstream of the aftertreatment system adopts an SCR efficiency monitor for diagnostics and tampering. SCR health is determined through a functional monitor that checks the NOxconversion efficiency. Additionally the temperatures of the exhaust gas before and after the SCR catalyst are monitored to prevent overheating of the catalyst.

All in one

In the case of ‘all-in-one’, how is the module structured? Which rare earths make it up, how does the catalyzation process take place, what kind of regeneration takes place in the DPF?

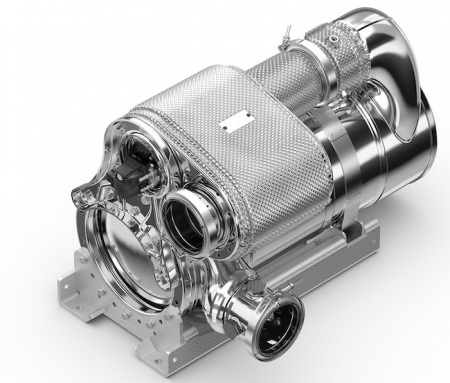

The modular exhaust gas aftertreatment (EAT) from MAN Engines excels due to its compact design and high flexibility in restricted installation spaces. It allows for a wide range of installation possibilities and system integration tailored to specific customer needs, as the individual components can be positioned differently.

Ammonia slip: how do you deal with the problem?

To prevent ammonia slip in the SCR catalyst a layer with platinum is integrated at the end of the catalyst, where the NH3isconverted to NO. Additionally, the NOx sensors and a control logic are able to detect NH3 and hence adapt the amount of injected urea solution.