QS Seamaster premiere at Seawork

At the forthcoming Seawork exhibition, in Southampton, UK, QS Seamaster will be presenting its range of thrusters designed according to the technical specifications of SAIM Marine, the marine Division of the Italian Saim Group

QS Seamaster makes its debuts in UK at the upcoming Seawork show, the largest European commercial marine exhibition which will be held in Southampton’s Mayflower Park from June 21st to 23rd.

QS Seamaster presents its full range of thrusters at the exhibition area of Atlantis Marine Power, their distributor in the United Kingdom.

QS Seamaster combines SAIM technical specifications with advanced production technology. It takes advantage of SAIM’s 30-year experience in design, supply, distribution and after-sales service in the marine field and of Quick Spa technical knowledge and excellence, an international leader in the manufacturing of marine accessories and on-board technical systems.

The full range encompasses all technologies and whose unique features stand out from all other thrusters available on the market.

QS Seamaster: all the models on display

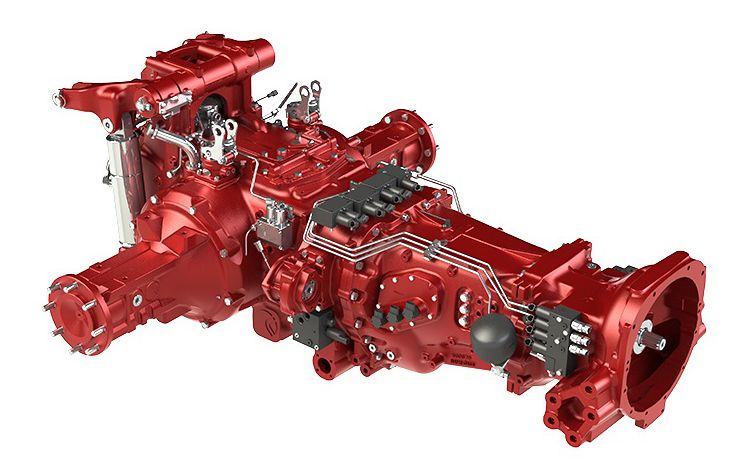

The range is 100% made in Italy and includes by now a comprehensive range of thrusters: DC electric thrusters, DC-AC brushless, AC 3PH, hydraulic, tunnel or retractable thrusters, ON/OFF and proportional (only proportional for the DC-AC brushless).

QSH 450-386 (hydraulic), QS 80-185 (DC), QSB 300-300 (DC-AC) and QSP 160-250 (DC Proportional) are the models on display at Atlantis Marine Power exhibition area.

All models are manufactured with high-resistant components which ensure the highest performance and efficiency from each motor. The hydrodynamic profile of the gear leg is designed to reduce turbulence, to enhance efficiency and reduce the noise level. The 4 or 5 blade propellers are built in composite material or in NiBrAl and designed to ensure the highest performance and efficiency from each motor.

Safe operation is guaranteed by virtue of a microprocessor-based control and management system preventing overheating or thruster interruption during normal operation. The aluminium anodic protection can be easily replaced while the unique-design flexible coupling protects the thruster structure from mechanical shocks.