MAN Stage V. The lion roars into the sea

MAN is Stage V compliant off-road and into the sea as well (EU STAGE V). As you know MAN knows no limits of application. When you say the word work associated with the word machine, you feel you have to be there. After onroad Euro6 came Stage V for NRMM. Now, at last, also for […]

MAN is Stage V compliant off-road and into the sea as well (EU STAGE V). As you know MAN knows no limits of application. When you say the word work associated with the word machine, you feel you have to be there. After onroad Euro6 came Stage V for NRMM. Now, at last, also for marine applications. Let’s read the official from the Bavarian company.

MAN Stage V for inland waterway transport

“MAN Engines expands its portfolio to EU stage V engines for inland waterway transport. In addition to the existing six-cylinder in-line engines there are four further power ratings which extend the power range from the current 290 kW to 882 kW (394 HP to 1200 HP). Thus the additions to the portfolio are two V12 engines, D2862 with 24.2 litres displacement and a power of 882 kW or 735 kW (1200 HP or 1000 HP). In addition there are two six-cylinder in-line engines with 12.4 litres swept volume and rated power of 412 kW or 368 kW (560 HP or 500 HP). The availability of these four additional power ratings is scheduled for the fourth quarter of 2021. «Additional power ratings and types of engine for EU stage V are a further building block in the continual expansion of our portfolio of marine engines.», says Claus Benzler, Head of Marine MAN Engines. Currently the engine manufacturer offers the MAN D2676 six-cylinder in-line engine as the LE487 marine propulsion unit at a power of 290 kW (394 HP) and as the LE328 as a marine auxiliary unit running at 1800 rpm and 1500 rpm.

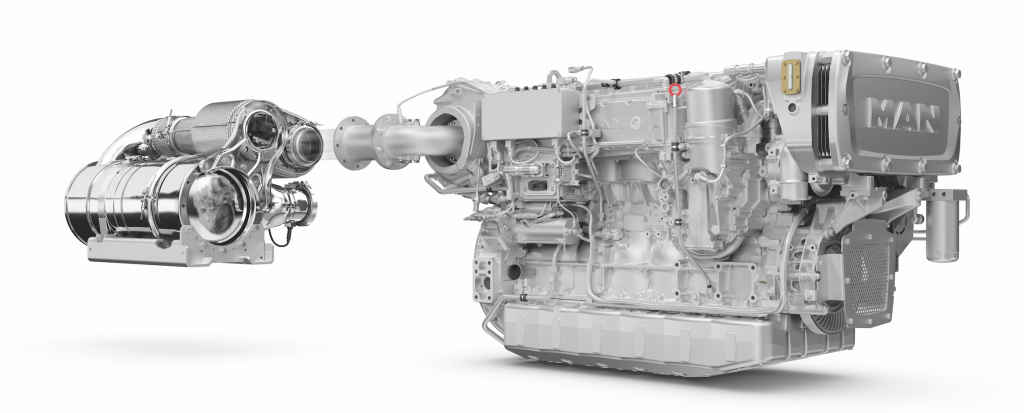

And now let’s talk about ATS

The solution ensuring compliance with the strict emission standards is the MAN Engines’ modular exhaust gas aftertreatment system. The modular EGA allows for a wide range of installation possibilities, since the individual components can be positioned differently, enabling flexible system integration tailored to specific customer needs. This offers advantages not only in confined spaces or situations where access is difficult, but also in meeting the different requirements of the emission limit values: For engines of power ratings > 300 kW used on inland waterway transport, the legislators have set higher emission limits per engine for nitrogen oxides (NOx = 1.8 g/kWh) and particulate mass (PM = 0.015 g/kWh). In addition the number of particulates is limited (PN = 1.0*1012 n/kWh). For this reason MAN Engines relies on an exhaust gas aftertreatment system with SCR and DPF for engines rated > 300 kW. At power ratings < 300 kW the statutory specifications for nitrogen oxides (NOx = 2.1 g/kWh) and particulate mass (PM = 0.1 g/kWh) are satisfied using an SCR system on its own without employing a DPF.

MAN Engines’ modular exhaust gas aftertreatment system for working boats was showcased at the International Workboat Show in New Orleans, La., back in late 2017. The system employed by the Man Engines business unit is all based on the expertise of MAN Truck & Bus SE. As one of the leading European commercial vehicle manufacturers, the Group has been successfully using SCR systems in its own trucks in high-volume production since 2006. As well as this, MAN Engines also benefits from the experience in fitting and installation gained from the agricultural and industrial sectors, where the technology has been in serial production since 2015 for in-line and V-engines. The EGA is also showing how practical it can be in field trials for working boats, which are currently running on Lake Constance and also in the Netherlands.”