SaMoTer Day, the picture of a changing sector

SaMoTer Day 2019, held on 29 October, did not just anticipate the format and novelties of the next edition of SaMoTer, the international construction equipment trade fair scheduled from 21 to 25 March 2020 in Verona. It was also, and above all, an opportunity to actually take a picture of the sector, thanks to a […]

SaMoTer Day 2019, held on 29 October, did not just anticipate the format and novelties of the next edition of SaMoTer, the international construction equipment trade fair scheduled from 21 to 25 March 2020 in Verona. It was also, and above all, an opportunity to actually take a picture of the sector, thanks to a research conducted by Prometeia and carried out with the support of Ance Verona, Anepla, Assodimi – Assonolo, Nad and Unacea, which reported data and trends from both a quantitative and qualitative point of view.

Let’s start with the wait for SaMoTer which, starting from next year, will be held in March and no longer in February. Not an easy choice, indeed, as stated during the event by the General Manager of Veronafiere, Giovanni Mantovani. Such a decision was taken «so that the event has the most correct location. So far, we are very satisfied with the exhibitors’ participation». It’s quite hard not to be, given that, as stated by the organizers at the beginning of October, registrations are +39 percent compared to 2017 and exhibition space +66 percent.

180,000 construction machines are working in Italy

A plus, it seems, also for the sales of construction equipment, as anticipated by the Secretary General of Unacea, Luca Nutarelli, who moderated the two scheduled round tables. In the first nine months of the year, according to the latest data, there was a satisfactory +13 percent, in contrast to the trend of the European market.

But let’s come to the survey, presented by Cristina Rossi and Giuseppe Schirone from Prometeia. The main target was to evaluate the fleet of machines in use in Italy, both owned and rented. The benchmark was a similar, though less refined, survey carried out in 2008, at a time when the market was at its zenith. The first important difference concerns the number of construction machines in operation, currently estimated at just under 180,000 vehicles, 52 percent less than 11 years ago. This is undoubtedly an impressive figure, but it is substantially in line with the market trend in the sector in recent years.

Of the 180,000 vehicles currently in use, the share of rental vehicles is close to 30 percent, a significant increase since the last survey. Just as the share of used machines in the total is increasing.

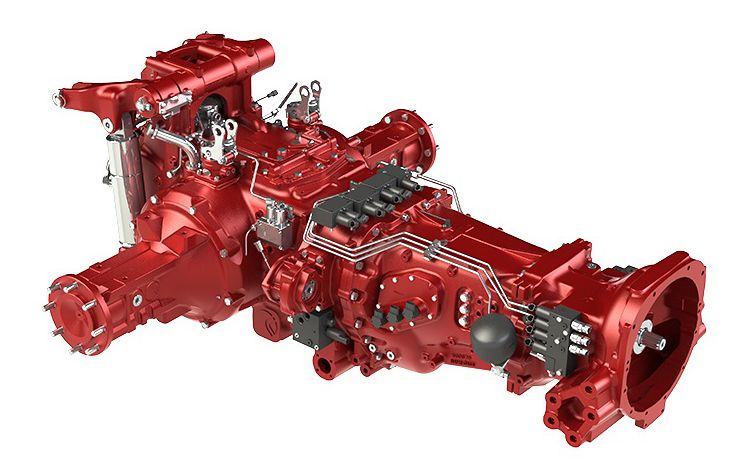

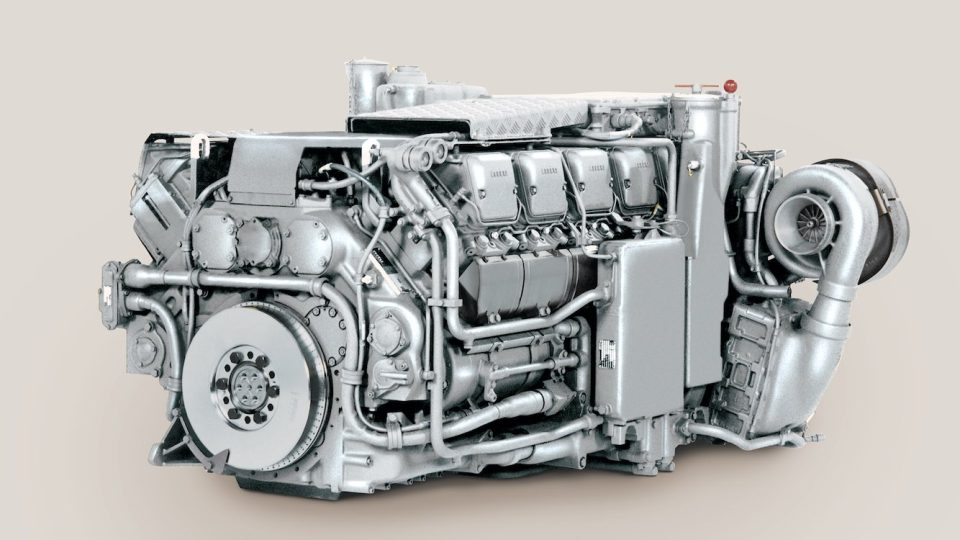

SaMoTer Day also dealt with engines

The survey presented at SaMoTer Day also highlighted an aspect particularly dear to our readers, namely the engines. Respondents were asked to indicate the stages of the engines mounted on their machines, from 1 to 5, with an increasing level of efficiency. The picture that emerged was that the overall fleet of hirers was more advanced and that, as we moved to the various types of machines, more attention was paid to controlling emissions in the earthmoving and road machinery sectors. Farms and, in general, small construction companies pay less attention to the environmental issues. The category that has most renewed the fleet in recent years seems to be the one engaged in the waste collection and disposal.

CONSTRUCTION EQUIPMENT IN ITALY IN 2018

Do we need ‘smart’ machines?

Reasons for buying and attention to ‘smart’ machines are the other macro areas that the research introduced at SaMoTer Day wanted to investigate. Why, in short, do people decide to change a construction machine? The search for greater innovation, the fleet expansion, tax incentives (which seem to work indeed in this sector…) even more than bank financing, automation and ancillary services. Other drivers are sustainability and lower noise levels.

In terms of smart machines, the users seem to be rather aware of the scope of innovations, although there are still many barriers that hinder investment. What construction equipment users are looking for is, in order, geolocation, operation monitoring, predictive maintenance, intelligent on-board systems, to name the most popular answers. The list does not lack the electric motorization.

An interesting fact, which can be seen, according to the authors of the study that drew the attention of the participants at SaMoTer Day, as a starting point for a more widespread spread of ‘4.0’ technologies, is that almost 4 percent of the companies interviewed stated that they had changed machines still working with smarter models. The intelligent driver, in short, has in some cases favored the decision to change the machine itself.