Agco Power: Duray and Tuorila on alternatives, regeneration and more

We already had the occasion to read about the “secrets” behind Agco Power through the words of Alexander Duray, manager, global engine sales, and Jarmo Tuorila, Director, sales and marketing. Now we can proceed by going deeper on themes such as marine engines, the partnership with Proventia, the possibilities for alternative solutions, regeneration and more […]

We already had the occasion to read about the “secrets” behind Agco Power through the words of Alexander Duray, manager, global engine sales, and Jarmo Tuorila, Director, sales and marketing. Now we can proceed by going deeper on themes such as marine engines, the partnership with Proventia, the possibilities for alternative solutions, regeneration and more in this second part of the interview…

THE FIRST PART OF THE INTERVIEW

And what about marine engines?

The marine division is all active, is aimed at the marine commercial, in low volumes, in the order of 150 units per year. We are also preparing for the IMO Tier 3 legislation coming in 2021.

Your partnership with Proventia?

Proventia is supplying many of AGCO aftertreatment systems, our engineering departments have been working together for a long time. We see mutual benefits and we share a common mindset.

AGCO operates in a glocal dimensions. In one hand we have four plants in the world: in Finland, in Linnavuori, in the town of Nokia, in China, in Brazil and in Argentina. In the other hand we work closely with our local partners. Talking about Finland, 90% of components come from the European region and it’s the same in China, where the 75% of components come from China. The common denominator is the focus on quality: we are not aiming to save few euros and compromise the quality.

LNG, hybridization and electrification?

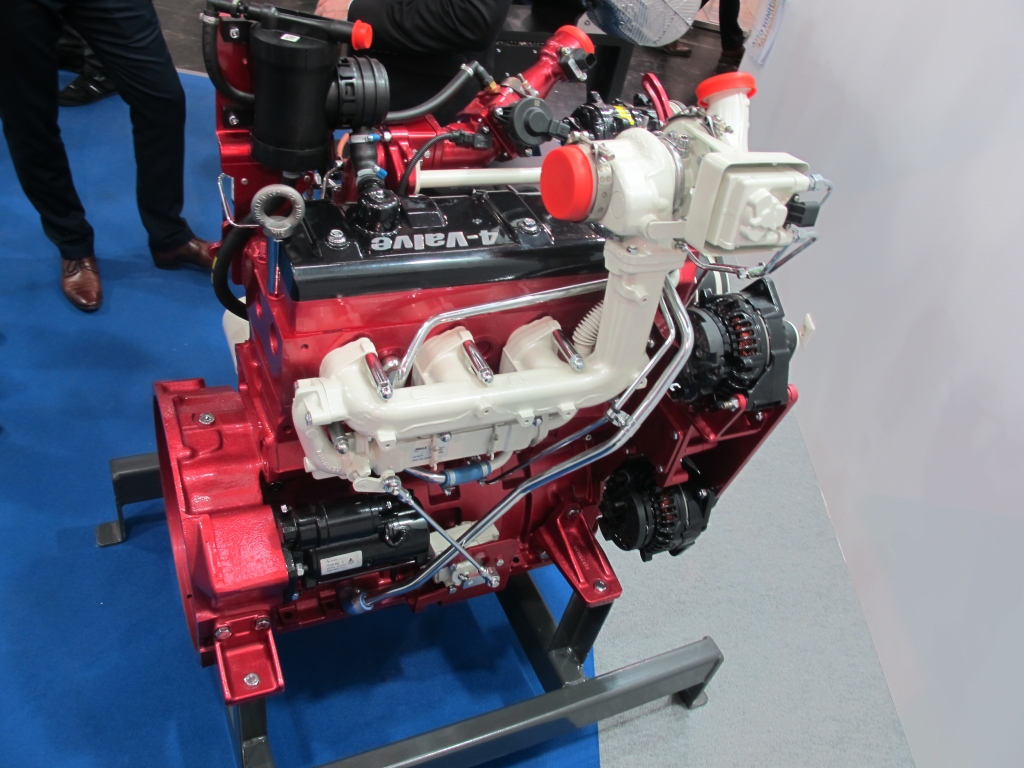

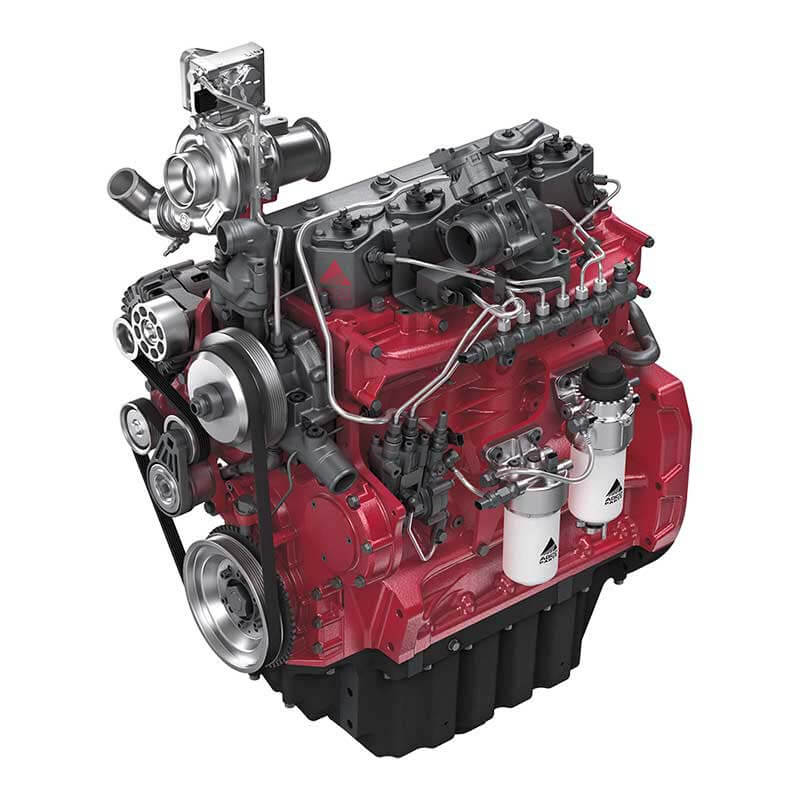

AGCO Power believes it’s very important listening the voice of governments and OEMs as well. We are monitoring the trends, however what we are pointing out is that diesel engine is remaining as primary source in the industrial sector. We’re investing more than 100 millions euros for engine development and refurbishing our Linnavuori plant. We’re renovating the operations, for a vertical integration and for updating the production facility.

Biofuels are getting interesting from waste, diesel is still on the way, OEMs can’t use a 10 ton battery for the electrification of the big machines. If anything, we believe in hybridization for the electric drive of some electronic accessories. Last year we setup a new organization for R&D and we start working even more closely with University of Tampere.

We don’t see electrification replace diesel in off-highway vehicles. It could be a good option for the light-duty vehicles: if you work for a short period, if you can recharge and recover energy. Obviously a vehicle like an open field tractor can’t work with the cables.

What about your remanufacturing business?

Last year we remanufactured 1,500 engines. For OEMs it is the opportunity to give new life to their vehicles. It is AGCO Power’s contribution to the TCO of companies. Depending on the conditions on the engine we sell to the customers completely remade engines with similar specifications, with warranty and reimburse for the old engine.

Regeneration?

We use DPFs with platinum coating and also a very advanced thermal management system. Our target is no active regeneration during the cycle work of the machine but only during service intervals. Otherwise we manage just with passive regeneration. The customers can’t and should not need to stop in the middle of the working day.

Powerpack and customization?

We start with different engine layouts, we’re also open to design new components for customers. If the engine length isn’t fitted for the application AGCO Power is able to arrange new pipes and redesign the EAT location. We can also supply the urea tank, we’re flexible and open to accomplish the customers’ needs. In the future we are including powerpacks to our offering as well. With us the customer has possibility to talk directly with us, not only through the local dealers. That is true customer service.