Battery research: ystral cooperates with Fraunhofer FFB

The machine and plant manufacturer ystral supports the project Battery Cell Research Manufacturing in Münster (Germany) with a mixing and dispersing system in the Fraunhofer “FFB PreFab”, which is intended for testing manufacturing processes as well as new recipes for battery cell production. The start of the test operation on the ystral system is scheduled for the end of next year.

The Fraunhofer FFB, which will be created within the scope of the project, is to enable industrial companies along the entire value-added chain of battery cell production to test selected process steps or entire manufacturing processes with regard to material, production technology, energy and resource efficiency, quality, throughput and costs, and optimise these for their purposes. The first building of Fraunhofer FFB, “FFB PreFab”, which is currently under construction, will receive a sample line for small-scale battery cell production. The insights gained from this are to be used for a test line for medium-scale production research, and a manufacturing line for large-scale battery cell production, which is to be ready for use in another building – the “FFB Fab” – from 2025.

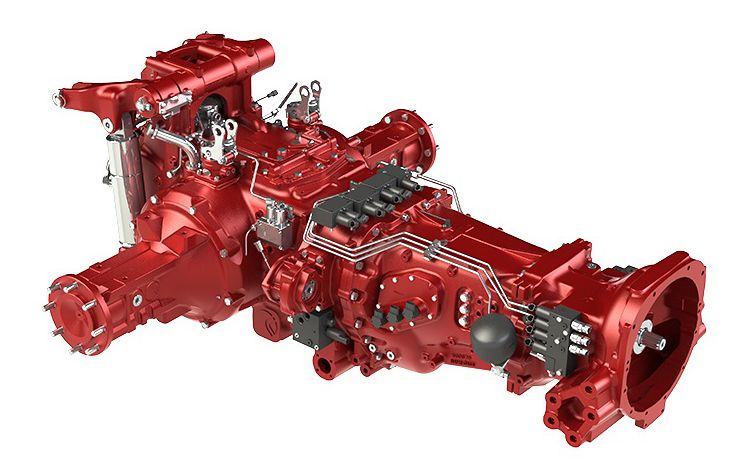

R&D system with dispersing system YSTRAL Batt-TDS

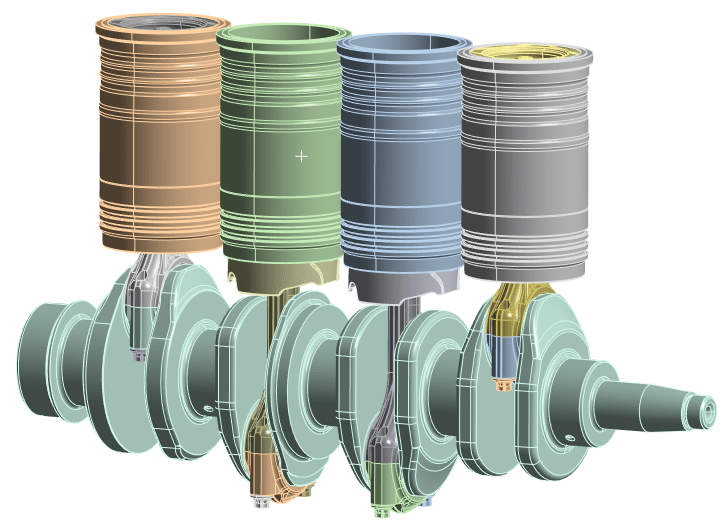

The core element of the ystral system installed in FFB PreFab will be the YSTRAL Batt-TDS Navi machine, a dispersing system for the production of lithium-ion-electrode slurries with scheduled quantities up to 12 l, which was developed specifically for R&D purposes, enabling realisation of the entire slurry mixing process within a few minutes.

“The YSTRAL Batt-TDS absorbs powder materials into a liquid flow dust-free under vacuum, thus enabling dispersion of the powder particles within milliseconds”, says ystral Managing Director David Manke, who has helped shape the development of the Batt-TDS from the start. “The dispersion of polymer binding agents, conductive carbons and abrasive active materials is adapted according to their specific physical properties and structures in the process.” In addition to the Batt-TDS Navi, the YSTRAL Batt-TDS is also available in three further sizes for medium- and large-scale manufacturing processes for cathode or anode slurries with a capacity of up to 5,000 l/h.

In addition to the YSTRAL Batt-TDS Navi, the ystral system in the FFB PreFab also includes handling equipment for the processing of raw materials in powder form. Sacks with hazardous substances such as NMC can be safely opened in an isolator, and the raw materials in powder form can be weighed. The powder materials are then fed to the Batt-TDS via a docked powder hopper without contact with the environment. In addition, part of the ystral system is a flexibly extendable control, which enables connection to primary control systems of the research institution. The R&D system is completed by several movable buffer vessels with installed mixer and a capacity of up to 50 l.

According to the current schedule, ystral will support the first tests of battery manufacturers in the research institution in Münster from the end of 2023, and be present on site with training and seminars.