A closer look to Baudouin new gas engines (Part I)

Baudouin new gas engines. The French company approaching the gas engine market is quite a big news. We couldn’t talk to them at MEE, due to the coronavirus outbreak that did not allow the company to take part in the exhibition (here’s a previous post about the engines). However, we had the opportunity to go […]

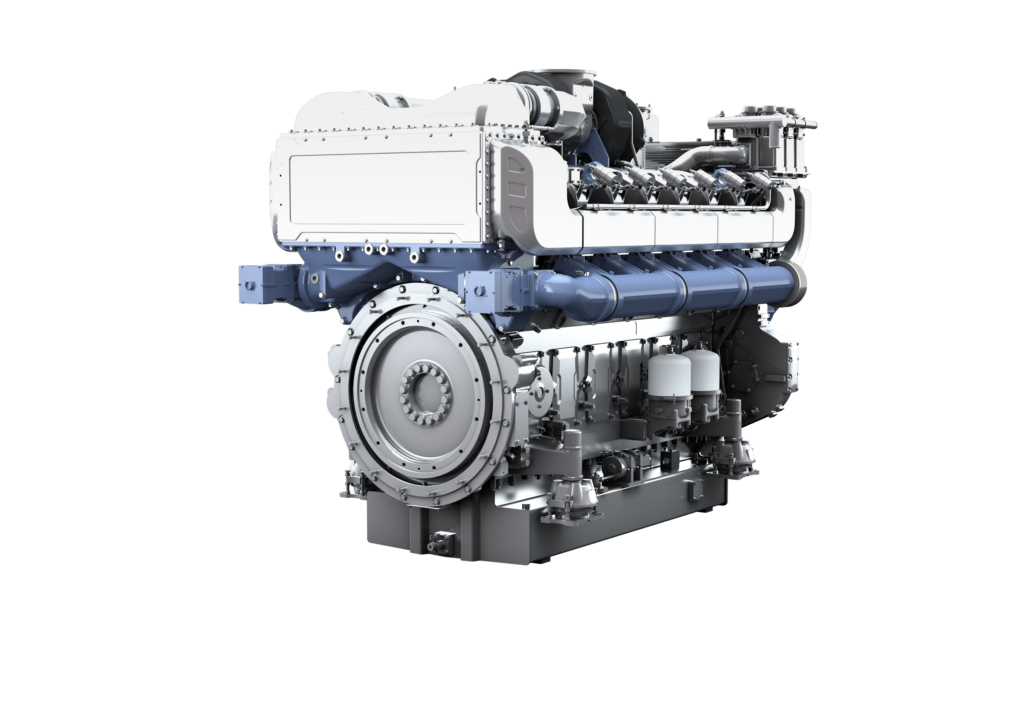

Baudouin new gas engines. The French company approaching the gas engine market is quite a big news. We couldn’t talk to them at MEE, due to the coronavirus outbreak that did not allow the company to take part in the exhibition (here’s a previous post about the engines). However, we had the opportunity to go into details with Richard Flynn, Product Planning & Development Director at Baudouin. This is the first part of the interview. We’ll publish the second part next week.

Let’s talk about Baudouin new gas engines. Did you choose lean burn or stoichiometric injection? Why? What kind of coils did you choose?

Lean burn engines fit the expected profile of our initial gas customers who are looking for products offering extended running hours, competitive TCO, high efficiency, and low exhaust emissions, all with the potential to incorporate co- and tri-generation technologies.

By burning a lean mixture of fuel and air, our gas engines can significantly reduce the combustion temperature and emit up to four times less NOx than a comparable diesel engine. As a result, we achieve a high-power output and a reduced carbon footprint which will help meet local emissions standards while delivering constant and reliable power.

Are gas engines available also for biogas and alternative gases?

Our PowerKit Gas engines are developed to accept biogas and alternative gases, as we know this is going to be one of the major developments over the next decade. Operators are using more diversified sources of gaseous fuels and embracing cogeneration systems (also known as Combined Heat and Power, CHP) in their quest for more sustainable, efficient energy solutions. CHP not only drives higher efficiency and reduces operating costs, but also helps customers in agriculture, hospitals or wastewater treatment comply with emissions standards.

In some countries, using CHP systems even allows the user to earn carbon credits, which can be utilized to offset other emission sources.

How did you choose the engine ratings? What are the most popular power levels for stationary gas engines?

The ratings were defined to solve most of our customers’ needs, from low kVA requirements to several megawatts of continuous power with a high efficiency output. The range spans from 50 kWm to 1.5 MWm, which covers a wide range of applications such as industrial plants, supermarkets, hospitals, agriculture, and more. In the same way that we are continuously improving our Diesel PowerKit range, we will continue listening to our customers to deliver additional ratings or adapted models if we see that there is a high demand for other products.

Are the gas ones the same engine blocks of the diesel versions?

The new gas engines share the same engine block design as our diesel engines that have proven their reliability, durability and high-power density in both the harsh marine and powergen environments. This makes our gas-fueled engines a competitive choice for OEMs in the prime, standby, peaking and cogeneration power market, scalable to the customers’ needs and locations. For OEMs using both diesel and gas engines, utilizing a single engine block design makes it possible to rationalize common spare parts and provides economies of scale for their parts inventory.

(To be continued…)