Bonfiglioli’s strategy from Bauma Munich 2019. The words of Marco Cesari

The last Bauma Munich 2019 was the presentation event of Bonfiglioli ECGenius, the mechanical transmission with continuous variation, of the 709CE translational reducers and of the gearmotors for rotation and translation 701TE and 701CE for mini electric excavators. Even the Internet of things has become a significant part of Bonfiglioli’s business. At Bonfiglioli, they usually […]

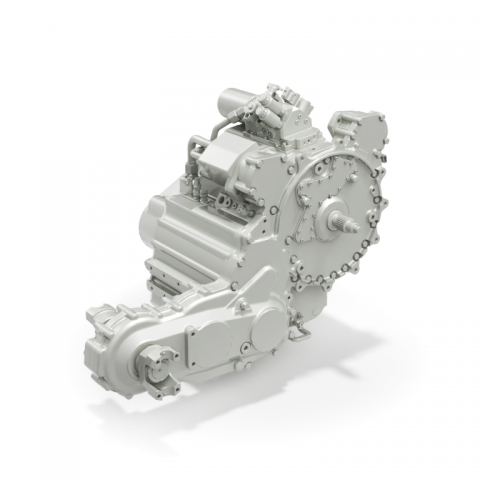

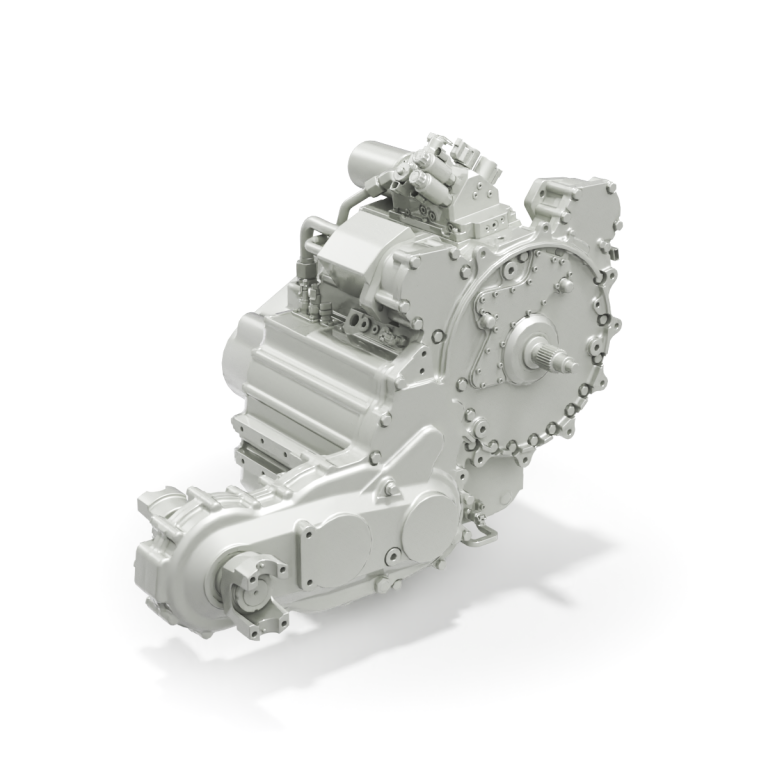

The last Bauma Munich 2019 was the presentation event of Bonfiglioli ECGenius, the mechanical transmission with continuous variation, of the 709CE translational reducers and of the gearmotors for rotation and translation 701TE and 701CE for mini electric excavators. Even the Internet of things has become a significant part of Bonfiglioli’s business. At Bonfiglioli, they usually say: «Thanks to the combination of inverters, sensors and algorithms based on Bonfiglioli’s know-how, it is possible to measure in real time a series of variables coming from the mechatronic chain, such as the flow, the torque, the speed, vibrations and temperature. These data are then transformed into information concerning processes and faults». With Marco Cesari, General Manager of the Mobile and Wind Solutions Business Unit, we have expanded the analysis of the strategic side.

The implementation of sensors brings a wide range of opportunities: from the survey of the temperature and the state of wear and residual life of the oil, up to the patterns of vibrations. Together with a bearing manufacturer we are developing a torque sensor. We have an eye on the environmental impact and the other on the end customer, who must maximize profit, efficiency and machine downtime. This means collecting all the data and decrypting it, individually and as a set of data, to manage information related to predictive maintenance. We are testing the application of sensors on gearboxes without thread and housing, adapting them for the purpose.

The application could therefore be retrofit?

We imagine a generation of “native” reducers, with cables and positions to accommodate these sensors. But retrofit is also a possibility that can be considered.

Let’s talk about electrification.

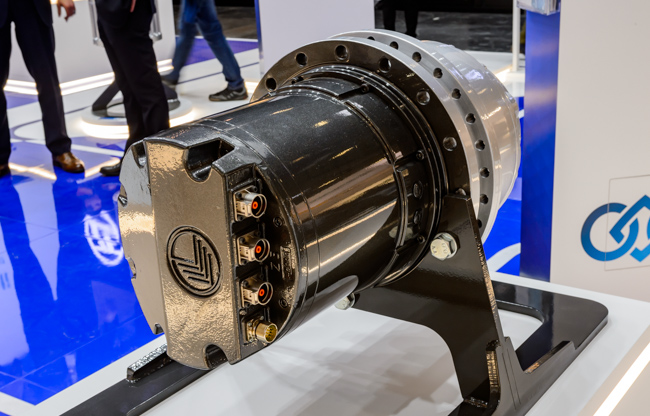

We have developed two prototypes of mini-excavators, in the context of the total electrification of both the translation and rotation parts, including a gear motor with an electric motor, which we develop. We want to be ready to meet any market need and play ahead of our customers’ requests. We will complete the work with the control part, concerning the inverter. We want to experiment as much as possible with electric mini-excavators, because you can only experience certain things on the field.

BONFIGLIOLI AND ELECTROMOBILITY

What signals do you receive from the market on conventional gearboxes and on the integration with O&K?

The German side of the brand is appreciated by the market. As for O&K we have created a logo with a stylized K and the &, which was not there before. The integration mark also goes through the color. From red we moved towards the gray representing Bonfiglioli.

In March, the German market recorded a slight decline in demand, but over the year the market in general is stable, and it will remain so until the end of the year. The United States are recovering, China is resisting and growing. We noticed a shift in volumes towards the top sizes of excavators, compared to the previous dominant size, the 20-ton one. Sany, for example, has expressed the need for heavy duty gearboxes, addressing O&K products.

Electric. How do you see it here in Munich?

There is a big difference compared to Bauma Shanghai, especially for basic machines, the core business of China’s off-highway. In Munich the new is emphasized, therefore the electric, despite the production remains mainly linked to hydraulics. What the market asks for are traditional machines, integrated with electronics and electrical components. The objective is the virtuous management of uptime, efficiency, and operating effectiveness.