Cummins microgrid and Australia. QS family

Cummins microgrid and Australia. When it comes to hybrid systems and cogeneration, storage systems and endothermic systems, Cummins has the expertise to organize an efficient proposal. We report what we received from Cummins regarding an application in Australia involving QSV91G and QSK60. Cummins microgrid and Australia. With the QSV91G Cummins Inc. installed Cummins QSV91G lean-burn […]

Cummins microgrid and Australia. When it comes to hybrid systems and cogeneration, storage systems and endothermic systems, Cummins has the expertise to organize an efficient proposal. We report what we received from Cummins regarding an application in Australia involving QSV91G and QSK60.

Cummins microgrid and Australia. With the QSV91G

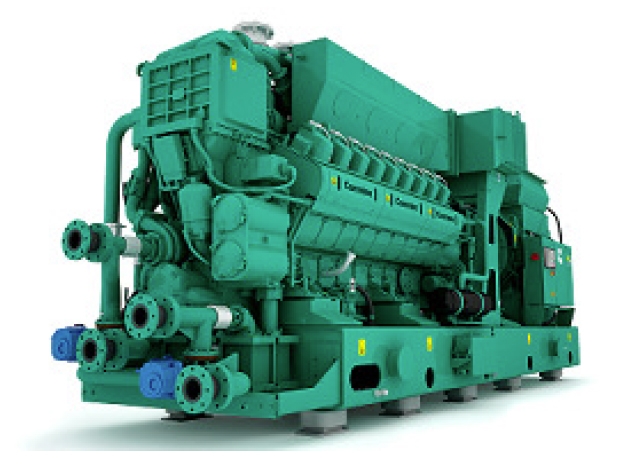

Cummins Inc. installed Cummins QSV91G lean-burn gas generators to provide continuous, reliable power at temperatures of up to 45°C to EDL’s hybrid renewable energy microgrid at Gold Fields’ Agnew Gold Mine in the northern goldfields of Western Australia. The Agnew hybrid renewable microgrid system – Australia’s largest – consists of a new off-grid 23MW power station incorporating gas, photovoltaic solar and diesel power generation, and 18MW wind generation, a 13MW battery and an advanced microgrid control system. During 12 months of operation, the 56MW installed capacity at Agnew is equivalent to powering 11,500 homes and will abate 46,400 tonnes of carbon dioxide – equivalent to taking 12,700 cars off the road. All the energy produced at the site is used by the power station. To meet the crucial requirement of continuous and reliable power at temperatures up to 45°C, Gold Fields utilized nine Cummins QSV91G gas generators. The QSV91G generators can operate in high ambient conditions and provide high impact step loads and fast ramp rates while maintaining power quality. In addition, Cummins also installed two QSK60 diesel generator sets to provide additional power during peak periods of demand, in addition to providing the ability to black start the power station in the event of a power outage. A Cummins digital master control (DMC8000) was also installed to communicate with EDL’s microgrid controller to balance the power demand from the mine.

David Eccleston said

David Eccleston, Technical Sales Support Lead, Cummins Power Generation, said, «the QSV91G lean-burn gas generator at the power station is designed to provide Gold Fields with a solution that will provide continuous and reliable power in high ambient conditions to ensure the project can be a success». «We’re pleased to be working with EDL to deliver this landmark project, which will provide the Agnew Gold Mine with more than 50% renewable energy over the long term, without compromising power quality or reliability», said Eccleston.

Gold Fields is one of the largest global gold mining companies in the world, with nine operating mines and one project, including the Agnew Gold Mine. Gold Fields wanted to create an innovative hybrid renewable energy solution at the site, which has operated for over 30 years, with an annual gold production of approximately 220,000 oz per annum. To ensure this project was a success, Cummins collaborated with global distributed energy producer EDL, which was selected due to its track record in providing sustainable, reliable energy solutions for remote operations and communities.