Cummins unveils integrated drivetrain concept at IAA 2024

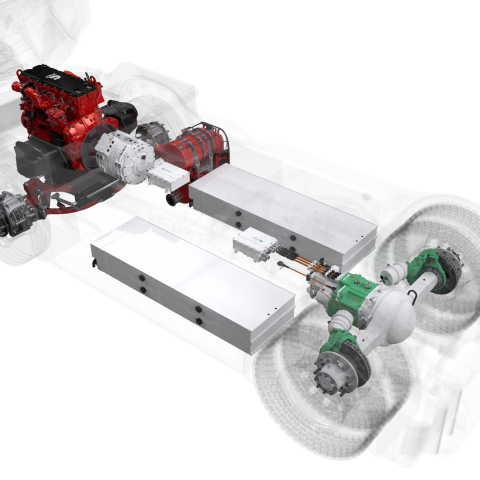

The drivetrain features advanced diesel and hydrogen internal combustion engines from its Cummins HELM platforms, as well as front and rear axles, brakes, aftertreatment systems and technologies from Accelera by Cummins.

Cummins presented its latest innovations at IAA Transportation 2024, with an integrated drivetrain concept designed to highlight the company’s broader product portfolio and continued commitment to providing flexible, sustainable power solutions.

Read also: Cummins CEO underscores energy transition opportunities at IAA Transportation 2024

The integrated drivetrain utilises Cummins’ extensive product capability to highlight three powertrain options – advanced diesel, diesel-hybrid and zero-carbon hydrogen – demonstrating the company’s multi-solution approach to supporting vehicle manufacturers with upcoming European emissions standards.

The drivetrain features advanced diesel and hydrogen internal combustion engines from its Cummins HELM platforms, as well as front and rear axles, brakes, aftertreatment systems and technologies from Accelera by Cummins, the zero-emissions brand of Cummins. The company’s acquisition of Meritor, Siemens Commercial Vehicles and Jacobs Vehicle Systems in recent years, means Cummins can now offer full powertrain capability.

Introducing Cummins HELM

Representing the company’s forward-thinking approach to power, Cummins HELM brings together advanced internal combustion engine technology and fuel flexibility in a way that is designed to meet the industry’s operational requirements while reducing tailpipe emissions.

Cummins HELM fuel agnostic platforms feature a series of engine versions that are derived from a common base. Below the head gasket of each engine are largely similar components and above the head gasket will have different components for different fuel types – either advanced diesel, natural gas or zero-carbon hydrogen. Each engine version will operate using a different, single fuel.

The X10 engine, with ratings from 240-335 kW (320 – 450 hp), extends Cummins’ heavy-duty performance down to a 10-litre displacement, whilst meeting Euro 7’s stringent ultra-low emissions standards. With peak torque of 2300 Nm, the X10 delivers exceptional engine response and vehicle drivability, setting a new benchmark for heavy-duty performance in 26-44 tonne truck applications.

Cummins’ driveline also features hydrogen internal combustion engine technology from its X15H – part of the company’s 15-litre platform. With power ratings from 298-395 kW (400-530 hp) and peak torque of 2600 Nm, the X15H offers an operating range comparable to current diesel engines, ideal for heavier-duty or longer-range applications. Slated for production toward the end of this decade, the X15H is displayed alongside Cummins’ production-ready 700-bar hydrogen fuel delivery system, with Type IV on-vehicle storage vessels from its NPROXX joint venture.

Hybrid powertrains

Featuring a diesel-hybrid concept, Cummins and Accelera have all the key technologies, individually or with integrated drivetrain options, for hybrid vehicles. Hybrid solutions can play a role in achieving carbon reduction goals in line with upcoming regulation, while infrastructure for zero-emissions technologies gain scale.

Jane Beaman, Vice President – Global On-Highway and Pick-Up Business at Cummins, said: “As the commercial vehicle industry in Europe approaches Euro 7 and CO2 HDV regulations, the need for diverse power solutions is more critical than ever. As we look toward the next decade, when carbon reduction targets intensify and infrastructure remains challenging, hybrid powertrains could help to eliminate range anxiety, enhance operational flexibility and contribute significantly to vehicle manufacturers’ CO2 reduction targets.”