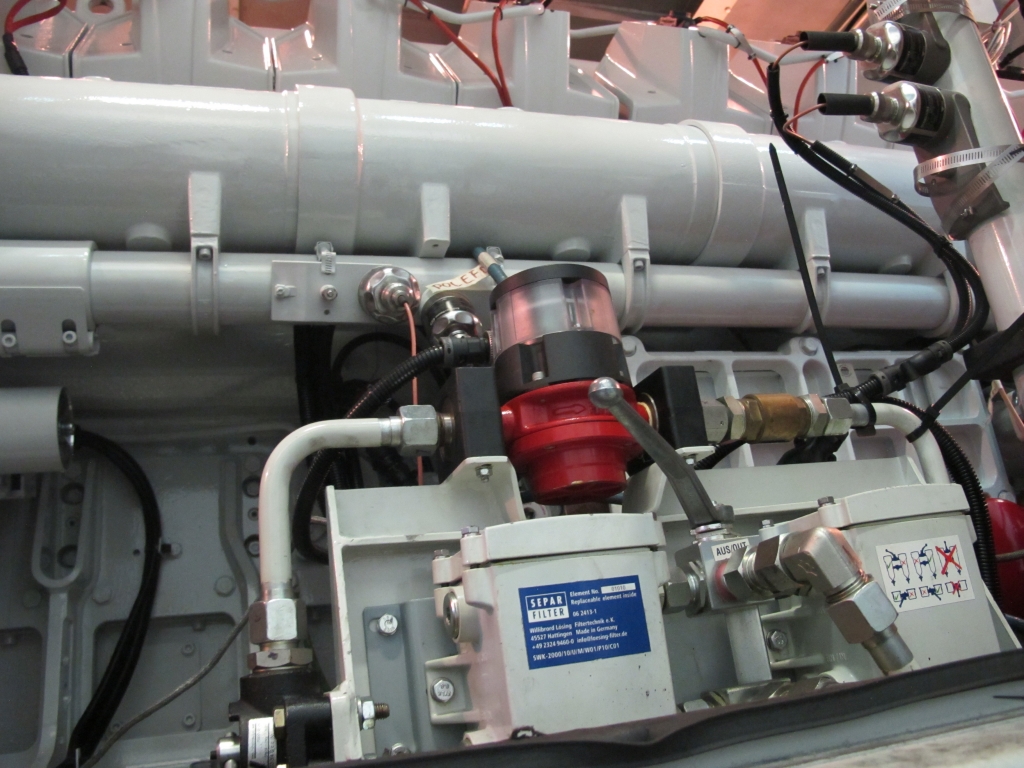

Diesel-generator 16V170C2Me by Isotta Fraschini

Gianluca Piscopo is the development manager of Isotta Fraschini. We met him in Bari (Italy), at the headquarters, on the occasion of the presentation of the 16V170C2Me diesel-generator for the Italian Navy PPAs (Pattugliatori Polivalenti di Altura), in the presence of Admiral Bisceglia, the President of Isotta Fraschini, Sergio Razeto, and Alberto Maestrini, General Director […]

Gianluca Piscopo is the development manager of Isotta Fraschini. We met him in Bari (Italy), at the headquarters, on the occasion of the presentation of the 16V170C2Me diesel-generator for the Italian Navy PPAs (Pattugliatori Polivalenti di Altura), in the presence of Admiral Bisceglia, the President of Isotta Fraschini, Sergio Razeto, and Alberto Maestrini, General Director of Fincantieri. Here is what he told us about Isotta Fraschini’s involvement in this project.

Where does the collaboration between Isotta Fraschini and this Fincantieri application come from?

Between Fincantieri and the Navy the exchange of ideas began well before the specific writing. This discussion also involved diesel generators. For the PPAs we came forward with our 1700 series engine, the 16-cylinder one with 170 mm bore, which the Navy knows well because it is used on other applications, the Fremm and the Orizzonte.

For the PPA project, we wanted to guarantee the absolute reliability of the product. A joint working group was created between IF, Fincantieri, Italian Navy, Navarm and Occam, which followed the development of the diesel-generator and compliance with the requirements. Since the initial phase all the actors, who are in effect also stakeholders have defined the validation processes.

Why this engine?

In our family the 16V170C2 is the one that reaches the power and Mtbo targets, therefore the maintenance interval. We underlined both the hours of annual use and the type of load. On the PPA the demand for electricity is considerable (due to the presence, among other things, of four radar systems). On applications like Fremm and PPA the diesel-generators are used for propulsion.

The main power is not given only by the auxiliaries, but also by the propulsive engines (Fremm) or by the shunting motors (PPA), which supply the major transients, because in normal use the ship stabilizes at a certain power load. The most severe condition is reached by maneuver. Despite the nominal power required by PPA and Orizzonte (even if the latter has a mechanical injection) it is the same, 1,600 kWe, the PPA duty cycle is much more difficult, because on Orizzonte the diesel engines average 50% of the load and undergo very few transients.

This led us to deeply revise the engine. The base is different and the pistons are still made of steel but designed to work with a coating equipped with anti-polishing ring, a device that prevents carbon deposits on the piston from corroding the coating.

GRIMALDI RELIES ON MAN ENGINES

Other engine features?

It does not have the EGR, since the Imo Tier 2 does not require it, and has a Bosch common rail of 1,600 bar. In the future we expect the transition to 2,200 bar. To reach Imo Tier 3 you can choose between Egr and Scr. We have chosen this last solution, making use of the collaboration with Ifog Engineering, because it supports the reliability of the engine and has a level of efficiency that makes recirculation unnecessary. It is a solution of industrial derivation, with a 40% urea solution. On the PPA it is not required that the SCR is always active. Neither the DOC nor the DPF are present.

How do you comment on a hypothetical variable speed?

The diesel-generator is at 60 Hz, at 1,200 rpm, while the Fremm runs at 1,800. In the past, Fincantieri did simulations to see if it was convenient to switch to a variable-speed generator, and considered this route potentially feasible. The problem concerns the electric machine, more complex and less durable, therefore less reliable, at least at the moment.