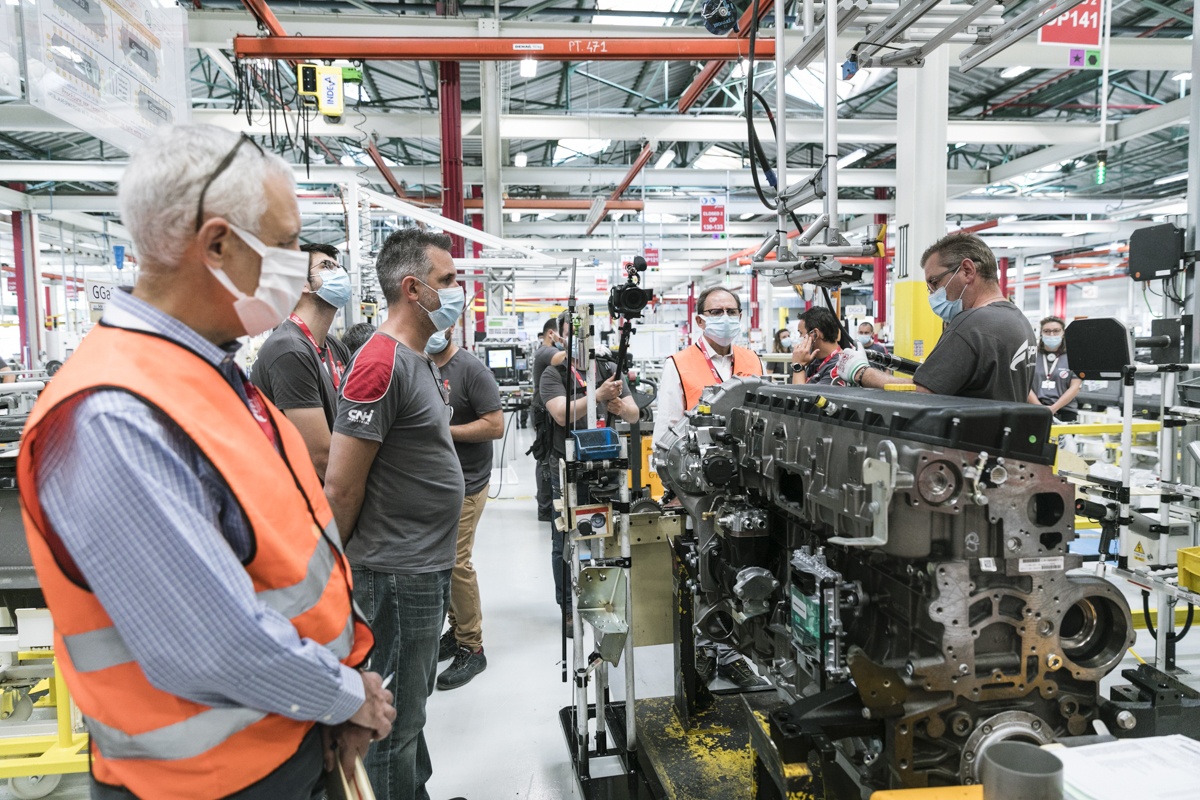

Bourbon-Lancy is the first FPT Industrial World Class Manufacturing plant

The WCM audit in Bourbon-Lancy noted progress and consistency across a variety of both manufacturing and managerial areas including cost deployment and autonomous maintenance workplace organization leading to the Gold Level designation.

FPT Industrial engine manufacturing facility in Bourbon-Lancy, France, has been awarded World Class Manufacturing Gold Medal. Such an important acknowledgement is the first one for an FPT plant, while it is the third time for a CNH Industrial site, after the IVECO Spanish plants in Valladolid and Madrid.

World Class Manufacturing (WCM) is one of the global manufacturing industry’s highest standards for the integrated management of manufacturing plants and processes. It is a pillar-structured system based on continuous improvement, designed to eliminate waste and loss from the production process by identifying objectives such as zero injuries, zero defects, zero breakdowns and zero waste. To certify improvements, a system of periodic third-party audits evaluates all of the WCM pillars, forming an overall score for each plant that is the basis for three achievement levels: Bronze, Silver and Gold.

FPT Industrial is World Class Manufacturing

The WCM audit in Bourbon-Lancy noted progress and consistency across a variety of both manufacturing and managerial areas including cost deployment and autonomous maintenance workplace organization leading to the Gold Level designation.

The Bourbon-Lancy plant is a proof of FPT’s commitment to sustainability. In addition to being the home of the most successful natural gas-powered engines on the market, the plant has also implemented a number of projects that focus on minimizing the impact of industrial activities and protecting the biodiversity of its surrounding environment.

On- and off-highway, marine and PG

The factory specializes in the manufacture of the Cursor engine series (here we talk about FPT Cursor 13 in its natural gas version) which offers 77 technical variations and over 5,700 different options. The production capacity achieves some 80,000 engines a year, with a workforce of close to 1,200 people. The engines manufactured in the French site, not that far from Lyon, meet the specific requirements of a range of applications, from on- and off-highway vehicles to marine and power generation.