FPT Industrial, power generation and Endress

Endress relys on FPT engines. Fpt Industrial has already done a lot for the power generation sector, by also bringing some of its “children” to the last MEE of Dubai. In particular, we are talking about names such as the S8000, the F5, the N45 and the Cursor series. One particular member of this family […]

Endress relys on FPT engines. Fpt Industrial has already done a lot for the power generation sector, by also bringing some of its “children” to the last MEE of Dubai. In particular, we are talking about names such as the S8000, the F5, the N45 and the Cursor series. One particular member of this family is now at the service of FPT’s partner Endress.

Endress and FPT together for the next step of power generation

Endress has developed and produced power generators for international markets since 1914. It operates in the sectors of mobile and stationary power generators, energy storage units and lighting pole systems. Endress is also part of Prettl Produktions Holding, a German group of companies active in the automotive, energy, electronics, components and systems and strategic build-up industries.

Both FPT Industrial and Endress have the same aim of developing products in response to customer needs and tailor-made solutions for all missions. This is why Fpt works on finding an effective solution to meet the requirements of the new emission regulations without impacting the genset’s layout. This resulted in HI-eSCR2, the well-known after-treatment solution by Fpt, already used in other applications. A solution that is also available to bring its benefits to the power generation segment.

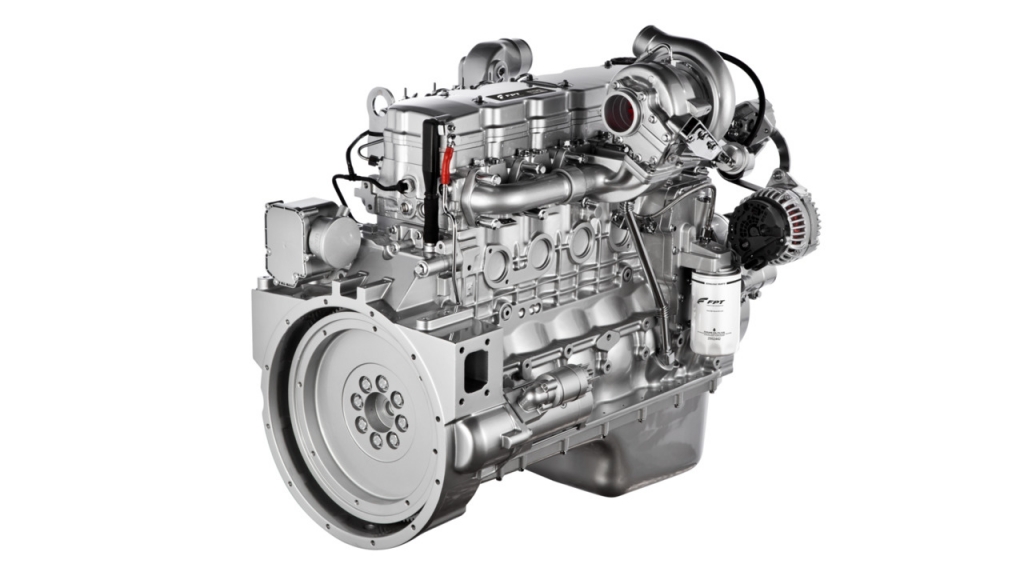

In particular, the HI-eSCR2 after-treatment system is part of the package that is at the base of the partnership between Endress and FPT. We are talking about the N67 200 kW Stage V engine installed on a genset frame, which has the same dimensions as an unregulated model. The N67 200 kW Stage V is able to provide high levels of power density, durability and reliability. It also offers easy maintenance and features long oil service intervals (up to 600 hours).

FPT INDUSTRIAL AND ART IN VENICE

A solution with different qualities

The N67 also requires very easy installation: the after-treatment pack is a preassembled solution which enables lean application. Moreover, being EGR-free it does not need additional cooling nor maintenance when compared to Stage IIIA products. Furthermore, it is extremely flexible since it can be installed both horizontally and vertically, front and top engine mounted.

The EGR-free system and the Waste Gate turbocharger combination also positively affect the total cost of ownership. With high fuel efficiency and low fuel consumption. The HI-eSCR2 also functions as a silencer that further reduces noise when compared to current Stage IIIA Fpt products.

As for emissions, the Stage V requires a NOx reduction of 90% and a PM decrease of 93%, enhanced by the introduction of a particulate number limit. This technology came exactly with this purpose based on Fpt experience with Scr solutions development. Furthermore, FPT’s Stage V solution is switchable. It can operate in compliance with both Tier 4 Final emission regulations and Stage V.

The collaboration with FPT provides Endress with the possibility to supply clients in all markets. Both regulated and unregulated, opening the doors for further growth also in Latin America.