Himoinsa and extreme climates. Let’s see what happens in Norway

Himoinsa provides us with a vademecum on the adaptation of gensets to the extreme climates. The incipit contains the reference to Darwinism. «It is not the strongest of the species that survives, nor the most intelligent that survives. It is the one that is most adaptable to change», stated the British naturalist Charles Darwin. We told you […]

Himoinsa provides us with a vademecum on the adaptation of gensets to the extreme climates. The incipit contains the reference to Darwinism. «It is not the strongest of the species that survives, nor the most intelligent that survives. It is the one that is most adaptable to change», stated the British naturalist Charles Darwin. We told you about it in this post.

If you want to go into details, we could deliver you an interesting case study. Where? In Norway. Before starting we’re pleased to mention another ‘iper-cold’ application, in Antarctica.

Himoinsa and extreme climates: 13MW of power in the Arctic

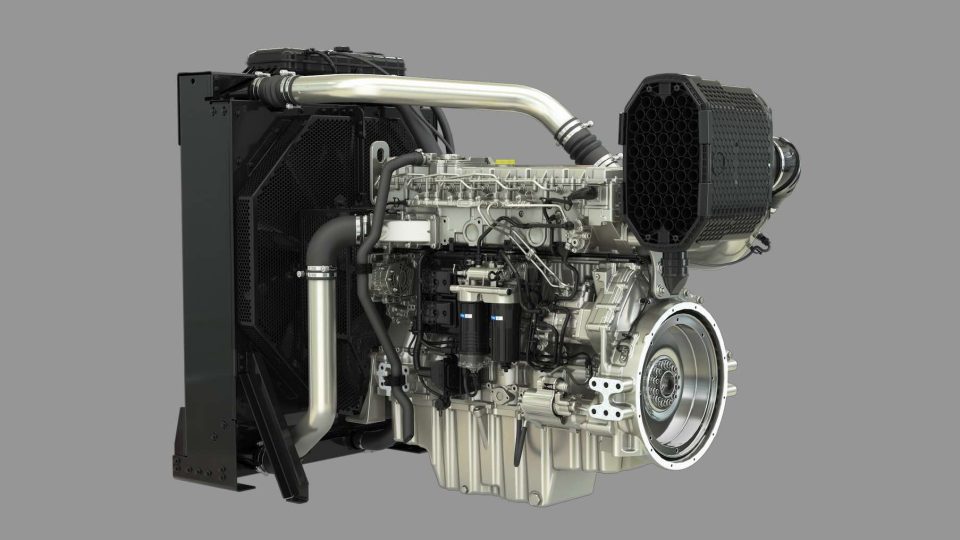

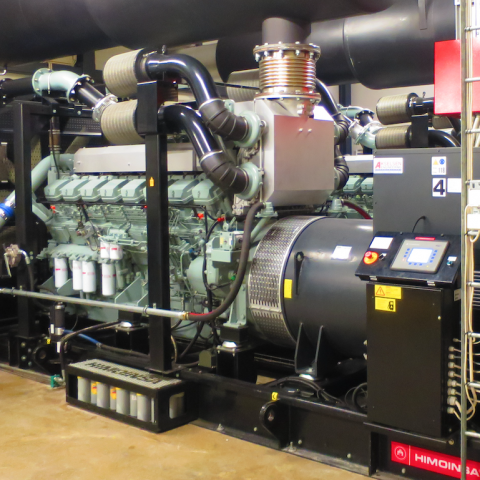

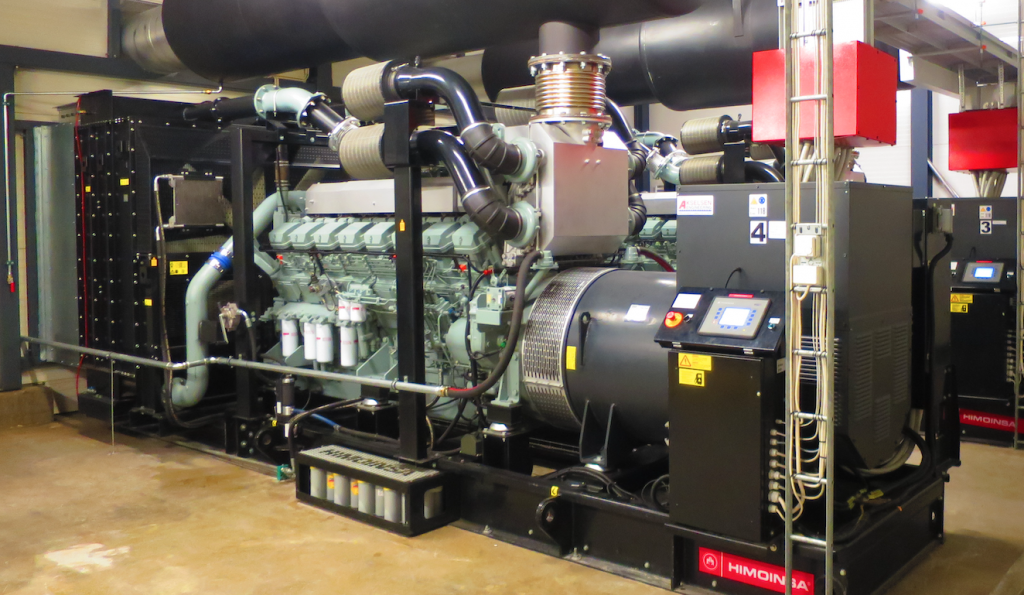

Himoinsa has supplied several HTW-1530 T5, HPW-800 T5, HTW-920 T5, and HTW-2295 T5 generator sets to one of the leading salmon farms in Laksefjord bay, northeast of Kunes (Norway) in the Arctic Circle. In total, nine generator sets have been installed in two different sites to supply standby and prime power to drive the oxygen and circulation tanks of the salmon fattening platforms. The generator sets supply 920-2295 kVA prime power but being able to provide up to 13 MW of standby power. They have an engine pre-heating system (temperature controlled for extended life of gaskets and hoses) and an anti-condensation system to combat the extremely cold temperatures of the Arctic, and have been placed in special rooms, insulated from the bad weather to protect all the electrical and mechanical parts of the generators. The system recirculates hot air from the radiator in to the room during operation to maintain 20°C in the room, even during winter time. This also reduces the amount of humid air being pulled in through the inlet vents.

Some details more

Installation A: 2x2xHTW-1530 with Woodward Easygen controllers. And also one HPW-800 with an old control system in the power station. The controllers are network connected, and the whole emergency power system is now remotely monitored and tested by Akselsen Engineering every month via network gateways.

Intallation B: 3xHTW-2295, and one HTW-920. This setup is a bit more complex, with woodward easygen controllers on the gensets, and woodward LS-5 tie breaker controllers on multiple places in the system. The system design was a compromise to be able to integrate the new emergency power system to the old buildings.

The land-based fattening platforms to which power is supplied are used to fatten up salmon to about 500g. These platforms are located in a remote region where a constant supply of oxygen and water circulation in the fattening cubes is required, to ensure the salmon survive this phase of the breeding process. Thanks to the RAS water recycling system, the breeding system requires less water and has become a more sustainable process.