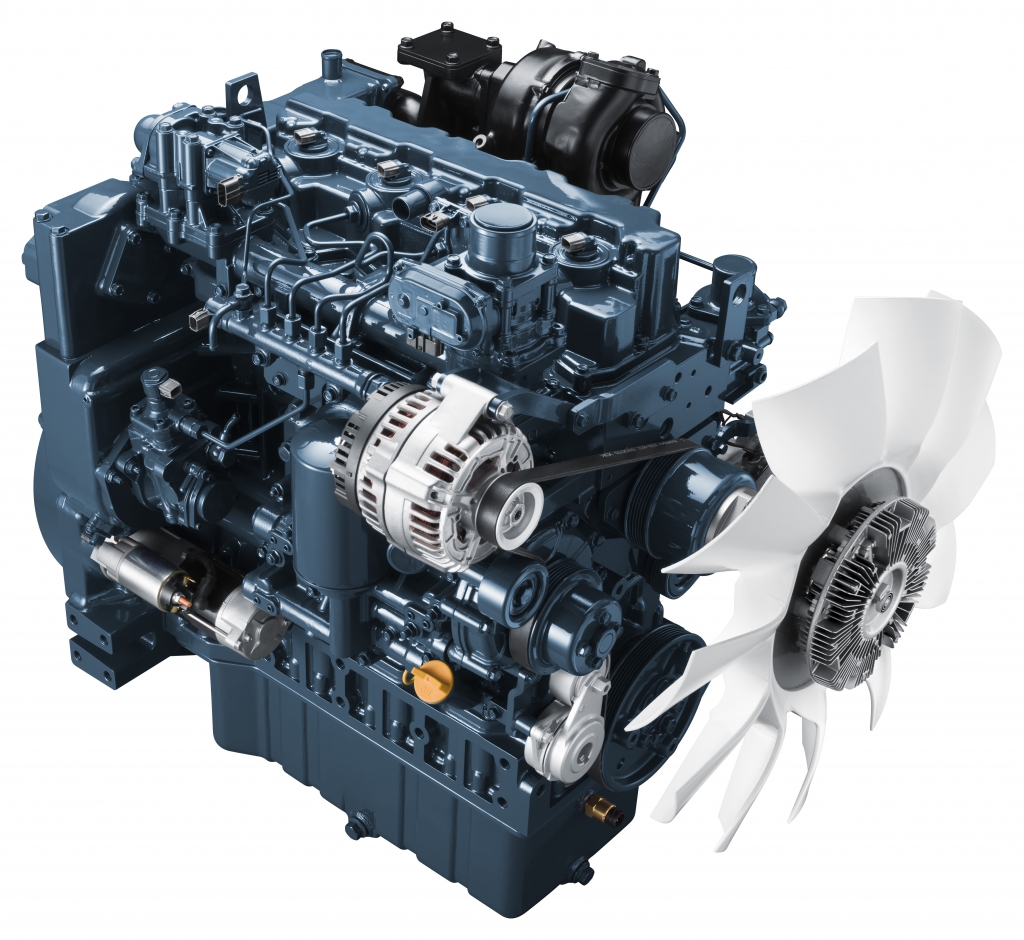

Kubota and the secrets of the Diesel of The Year 2019 winner: V5009

The Diesel of The Year 2019 award is in the hands of the V5009. We wanted to discover more about the winner and so we went directly to the source. We asked Kubota to tell us more about the V5009 that is surely going to be one of the main protagonists at Bauma of this […]

The Diesel of The Year 2019 award is in the hands of the V5009. We wanted to discover more about the winner and so we went directly to the source. We asked Kubota to tell us more about the V5009 that is surely going to be one of the main protagonists at Bauma of this year (8-14 April). Here’s what they shared with us.

DIESEL OF THE YEAR 2019: V5009

Can you tell us about the genesis of the V5009 project?

To understand the genesis of the V5009 we need to trace our history. Kubota’s engines have been the enduring “heart” of agricultural and construction machinery produced by Kubota since 1922, but in recent years, more than half of our sales have come externally from OEM manufacturers. We have become No.1 in the industrial diesel engines below 100 HP range, regularly receiving positive feedback from our customers around the globe, especially with regards to the quality and durability of our products. Many also mentioned their desire to use Kubota engines for larger applications.

In order to meet such demands and in turn grow our engine business by developing a new market together with our customers, we made the decision to develop the V5009 large-displacement engine for a wider range of applications, whilst maintaining the reputation for reliability that Kubota has gained over the years.

As market leader below 100 HP, the first challenge was to clarify market needs for a large industrial engine that reflected Kubota’s quality. There were differences, not only in the manner of thinking, but also in the overall concept that varied significantly from the engines created for small industrial needs.

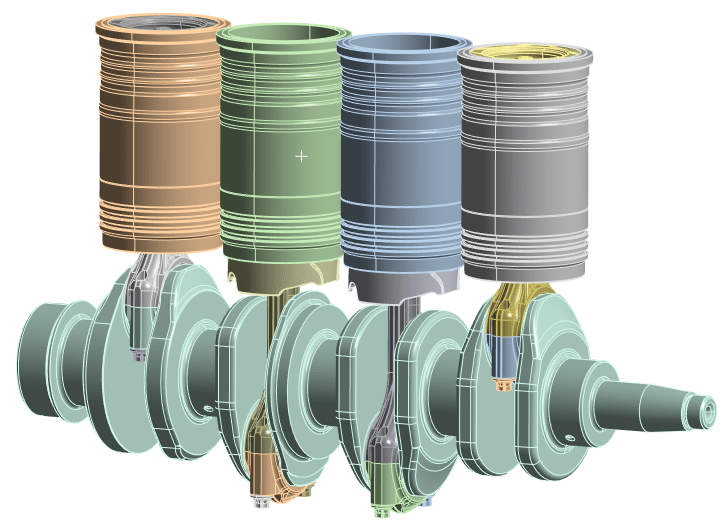

The greatest challenges were related to the strength of engine components and the degree of engine safety. It all came down to accurately calculating engine strength to ensure “Kubota Durability” as the performance level increased. Due to its significance to customers, there was no room for compromise when calculating the degree of durability required. In the process of increasing performance levels, repeated testing of this durability allowed us to improve the accuracy of input for strength calculations. Another important consideration was accurately discerning what had to be changed and what had to remain unchanged.

What are the main applications for the 5-litre displacement engine?

We believe that in keeping with the significant trend towards downsizing, the 5-litre engine will begin to be used by clients who might previously have looked at 6-litre or 7-litre engines. For the V5009, this may include excavators, rollers and compactors, wheel loaders, compressors and material handlers.

What are the key aspects on which Osaka’s R&D has focused?

To maintain both environmental responsiveness and durability, we have always strived to comply with the stringent regulations of the U.S. and Europe, which are advanced in terms of environmental conservation, but with no compromise in engine performance. For the V5009, we took the decision to make it comply with the upcoming Chinese off-road emission regulations as well as making this engine a global solution for OEMs who wish to use a common platform for their products.

In the development of the V5009, having state-of-the art environmental responsiveness was essential. Another challenge was to ensure it would have the durability that would allow it to keep performing at top levels under many diverse situations.

Reliability is a trademark for Kubota. How would you explain it, with reference to the V5009?

Maintaining the reputation for durability and reliability that Kubota has built up over the years while achieving an increased output required very solid strength calculations. Furthermore, the design concept and the approach of the new horsepower class engines differed completely from those of smaller engines, for which Kubota has been renowned for a long time.

Incorporating the component strength that could withstand greater horsepower into our design was a challenge but it has been rigorously tested to meet Kubota’s standards. We are now very confident that we can exceed customers’ expectations with the V5009’s durability and performance.

The V5009 is the first non-Western DOTY. Is it the right reward for the consistency with which Japanese engineering has believed in after-treatment and meticulous improvement of combustion in the chamber?

We are proud to be the first non-Western winner of the award, but it is not about West versus East, more a reward for Kubota’s meticulous engineering standards ranging from initial design to after treatment. This is not headline-grabbing fantasy engineering that had no chance of ever seeing the light of day. It is a response to listening to our client’s needs and an attempt to create a genuinely global platform that both responds to the “downsizing movement” and meets ever more stringent compliancy regulations around the world. Ultimately, the V5009 further helps us meet client demand for our widest possible range and scale of engines and we are proud to be able to name the DOTY 2019 as a key part of our offer.