Perkins and power generation, a closer look at the heart of the engines

Perkins and power generation. Karan Ohri is Global Marketing Manager of the Electric Power Business. It means he’s in charge of all the product range, from the smallest to the largest models, in the genset applications, globally. His point of view is a privileged one when it comes to the new challenges in power generation. […]

Perkins and power generation. Karan Ohri is Global Marketing Manager of the Electric Power Business. It means he’s in charge of all the product range, from the smallest to the largest models, in the genset applications, globally. His point of view is a privileged one when it comes to the new challenges in power generation. We made him some questions in Dubai. We split his answers in two posts: the second one will be published next week.

What has been on display at MEE 2020, then?

Last year, we introduced two new engines, which are still new to the range. One is a 9.3 litre and the other is an 18 litre. The common thing about both these engines is that they produce the same power as the next engine up in the size previous to them. So, the 9.3 litre produces 350 kVa, which is the same as the 13 litre engine, which Perkins will still make. The 18 litre makes the same power as the 23 litre.

We wanted to have a flexible product range in order to provide our customers with more options. Customers can then buy smaller engines, with a slightly better package also in terms of price and less fuel consumption. So, people interested in the prime power market, who are concerned about the fuel bill and maintenance costs, can buy these new engines. Other customers, such as hospitals, data centres, critical applications, residential markets, commercial towers, metro systems – where reliability is crucial for backup solutions – customers can still count on the existing series.

Perkins and power generation: what about the 4000 Series? Is there anything new?

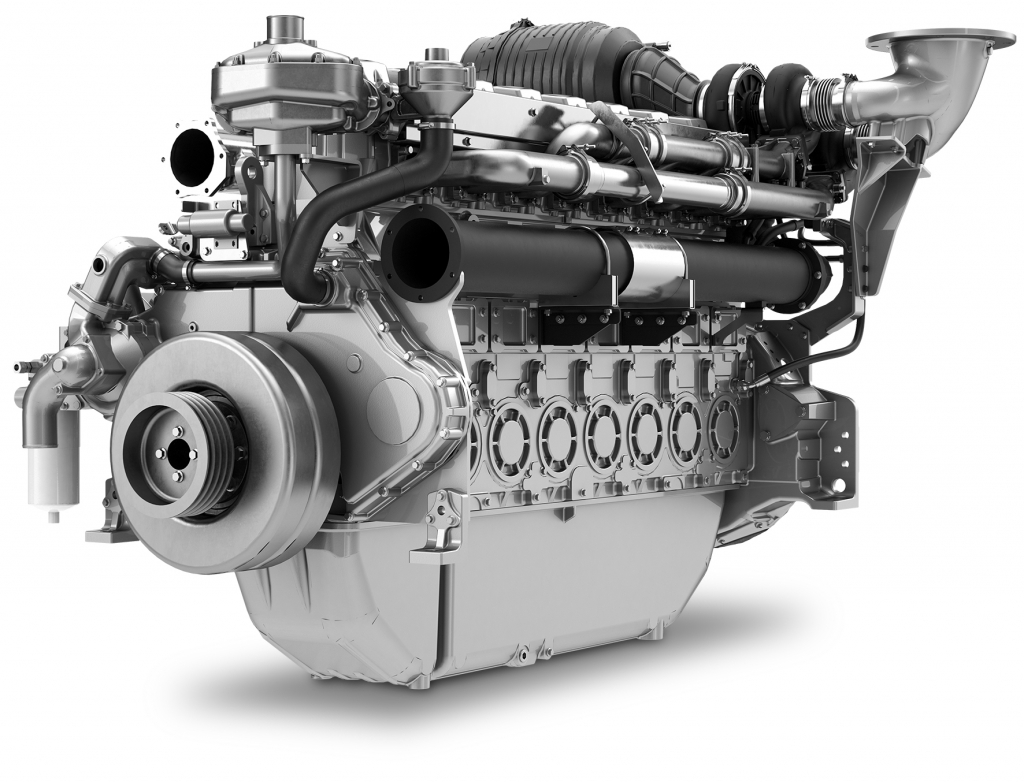

We’ve made several improvements to the internal design of the Perkins 4000 Series engines. Upgrading key components and aiming at basically doubling major service life and lowering customer operating cost. In fact, the engine used to require a major serviceafter 7,500 running hours. Now, the service interval has increased to 15,000 hours, which is market leading.

This means that, while from the outside the engine seems to be exactly the same, important improvements have been made inside the engine. We’ve upgraded some key components in terms of material or design. Some examples include upgraded valve seat design, valve angles and materials, upgraded bearing, piston liners and many more.

Talking about technology trends, what do you see for the near future?

I see two key emerging markets. One is the focus on 5G and the second one is about lowering the total cost of ownership (TCO). As for the latter, the main reason is that a lot of markets are getting better in terms of grid stability, so the gensets act as a backup standby solution. Some markets in this region, mainly Africa, need prime power solutions that run 8, 10, 12 hours a day. What we’re trying to do is optimize our product range in order to help the customers by lowering fuel consumption, longer service intervals, common parts across the product range to lower the cost to the customer to run and maintain a Perkins engine.

What can you say about the 5G? What’s changing for a major engine manufacturer like Perkins?

There are two kinds of markets within the telecommunication sector. In order to power the higher load demand from telecom towers to support 5G equipments, the market will have to upgrade to higher powered diesel engines. Alternatively, this could also support the growth of the hybrid market using solar, battery and smaller diesel engines as a complete hybrid package. The commercial viability and maintenance requirements will define the sucess rate of such a solution. Whether the solution chosen is a full diesel or a hybrid solution, it very much depends on the size of the fleet, the requirements of the applications and so on. For a customer of ours, a genset manufacturer, it’s all about optimizing the business model, then keeping the engines running and, for instance, a telecom tower powered up.

From my point of view, what we are supposed to do is support customers in their efforts to achieve these objectives with the right product. So far, we see two different markets: diesel still plays the bigger part, while we can see the hybrid one slowly coming up.

(To be continued…)