Scania and the “old school” Miller cycle solution

Scania Dc 16 and the Miller cycle Large engines with relatively low power outputs may have problems with after-treatment. This happens because the motor pumps too much air in proportion to the excess heat it generates. Scania engineers have solved this problem in a simple and elegant way with the Scania Dc 16. The 520 […]

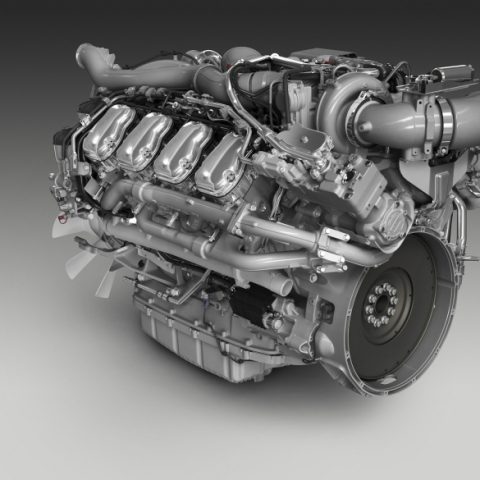

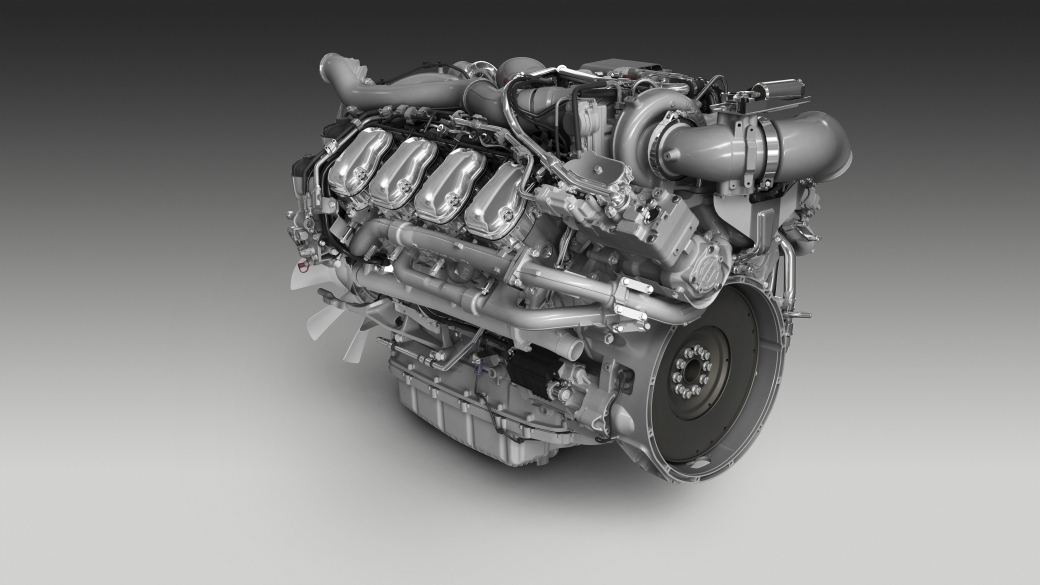

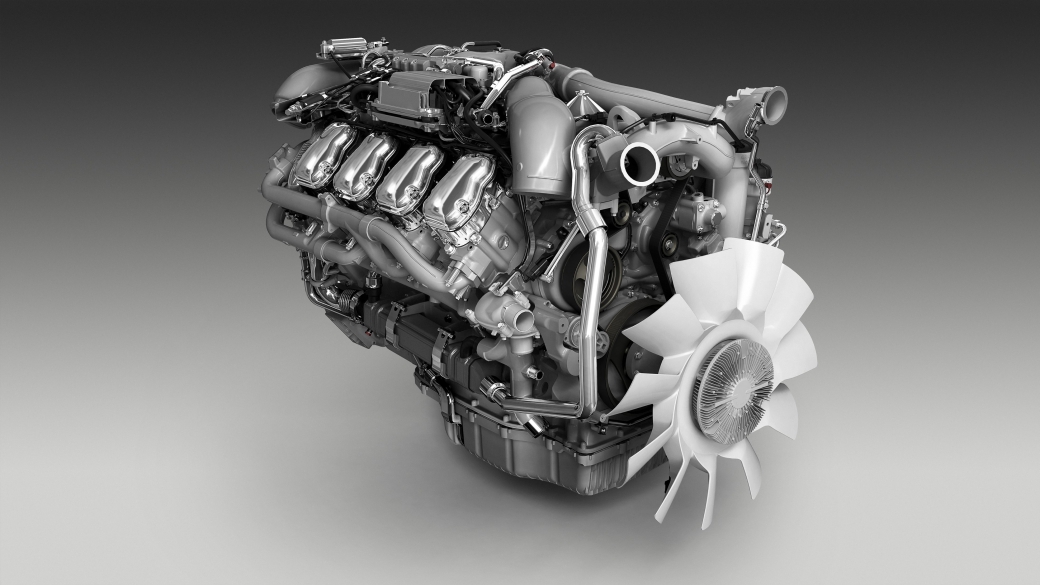

Scania Dc 16 and the Miller cycle

Large engines with relatively low power outputs may have problems with after-treatment. This happens because the motor pumps too much air in proportion to the excess heat it generates. Scania engineers have solved this problem in a simple and elegant way with the Scania Dc 16. The 520 hp V8, in fact, exploits a technology invented by the American engineer Ralph Miller in the 50s.

The use of special camshaft profiles ensures that the intake valves remain open a little longer than normal during the compression phase. This means that the engine actually gets less air. In turn, this allows it to maintain a higher working temperature, to the advantage of the Scr system. The solution of creating an engine that works according to the Miller cycle is an excellent example of Scania’s ability to produce simple solutions that add value to the customer without increasing costs. A possible, minimal defect could be identified in the slower increase of the torque from the minimum regime.

Scania Dc 16. The Miller cycle works wonders, says Roger Olsson

Roger Olsson, Chief Engineer of Scania’s V8 division, commented on the choice to rely on the Miller cycle. «Mechanically-speaking, it’s a relatively simple solution that achieves the same effect as if we had shrunk the engine’s actual displacement by about a liter. The Miller cycle works wonders for both after-treatment and reducing fuel consumption, with the only disadvantage being that the build-up of torque slows down marginally from idle. But in reality the difference is difficult to perceive, and instead it’s just striking what a perfect engine this is for long-distance trucks of 30 tonnes and over, where weight is not an issue. If you’re operating a heavy combination, if the road is hilly, or the average speed is high, then the new 520 engine is both a piggy bank and a power plant».

Illustration: Leon 2013

That unwanted but expected strike

With an official statement, in early July Scania announced the temporary suspension of sales and deliveries of its V8 engines. The cause is the continuation of a strike with a component supplier. The strike is preventing Scania from delivering, globally, more than 2,000 trucks with the V8 engines. The strike is affecting also sales of marine and industrial engines. It lasted from 14 June but already earlier this year this specific supplier had interrupted deliveries.

V8 engines represent a reference on the market, says Christian Levin

Christian Levin, Executive Vice President of the Head of Sales and Marketing, issued a statement on the current situation. «I am deeply sorry for this situation that prevents us from supplying our V8 engines. These, in fact, represent a reference on the market and are an important part of Scania’s DNA. Our commercial organization has already started to propose alternatives that allow the customers involved to meet the commitments made with their customers, using our 13-liter engines or other solutions of products and services. Nothing will be left unturned, in order to maintain the trust of our customers».