Sitrex news from Italy: the words of Diego Senatore

Sitrex moves on two fronts within the sector of agricultural mechanization: the one of equipment for haymaking, such as straw-throwers and presses, and that of self-propelled mixers. The main markets are both the Italian one and the international one. Sitrex, in fact, exports to more than 60 countries and it is developing in the United […]

Sitrex moves on two fronts within the sector of agricultural mechanization: the one of equipment for haymaking, such as straw-throwers and presses, and that of self-propelled mixers. The main markets are both the Italian one and the international one. Sitrex, in fact, exports to more than 60 countries and it is developing in the United States with Sitrex USA for the distribution of haymaking machines and mixers with branches in Columbus, Houston, Wichita and Omaha.

Wherever there is a self-propelled machine there is obviously an engine. Sitrex’s endothermic core has two reference points: Volvo Penta and John Deere Power Systems, the latter represented in Italy by Rama Motori of Reggio Emilia. We asked Diego Senatore, head of the technical office of Sitrex, to provide us with more information on the engine strategy.

Good morning, Senatore. Can you give us a brief identikit of your engines?

Torque curve and consumption. Both of our suppliers are perfect for hydrostatics.

And who would they be?

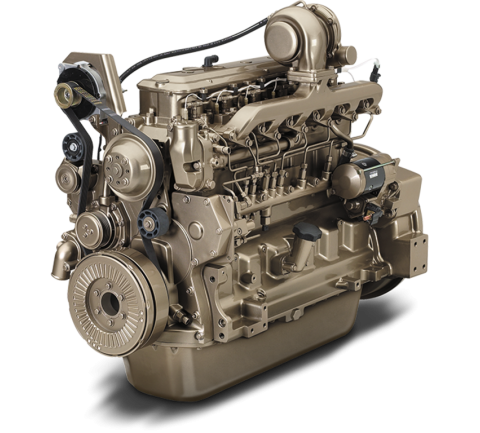

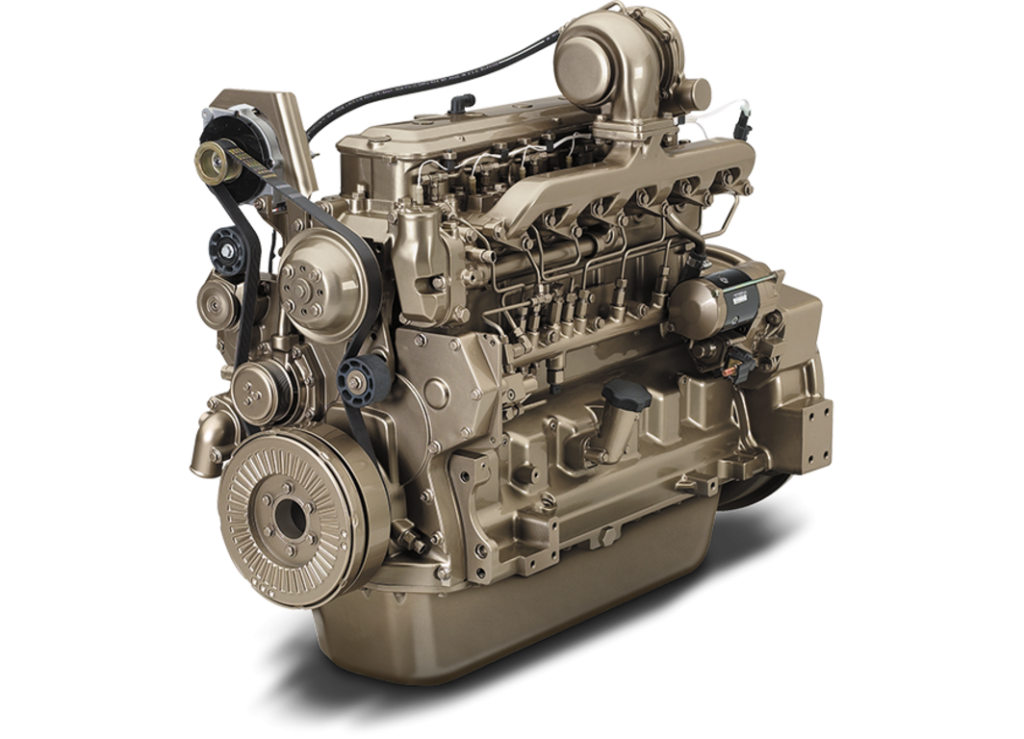

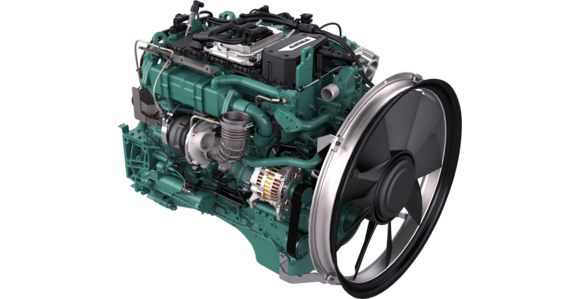

Our mixers are equipped with a 4-cylinder engine from Volvo Penta and a 6-cylinder one from John Deere. The division within Sitrex’s fleet occurs between single-auger and two auger applications. On the three ranges of single-auger machines, Premiere, Virage and Feedstar, we use the Volvo Tad 571 Ve, with an output of 129 kilowatts and 800 Nm, ready for Tier 4 Final regulations. For the Maxi model, on the other hand, we rely on John Deere, to be precise on the 6068, in the 165 kilowatt version with a torque of 1,000 Nm at 1,600 rpm.

We are historically linked to John Deere, together with whom we have managed the approvals for Stage IIIA, IIIB and Stage IV/Tier 4 Final. We have differentiated our engine portfolio so as to have a second supplier. The prototype was really good, both in terms of consumption and torque. Volvo suits well the hydrostatic application.

JOHN DEERE AND THE 13.6L AT BAUMA 2019

Stage V. Will there be changes in terms of suppliers?

No, we are satisfied with both Volvo and John Deere, with whom we are facing development towards Stage V. We appreciate John Deere’s evolution both in terms of consumption and in terms of extended warranties. With the rear engine the application is easily accessible, also in the allocation of the Dpf and the Scr. John Deere started early, fitting the complete after-treatment system. For Volvo there will be a need for deeper intervention, with the addition of the Dpf. Yet, the large space in the engine compartment allows us to implement the upgrade without complications.

Alternative fuels?

For the moment we focus on diesel. There will be developments, but alternative fuels require longer development.

VOLVO PENTA AT BAUMA 2019 WITH ITS STAGE V SOLUTIONS

Danfoss and Poclain?

All Sitrex self-propelled machines have Danfoss electronics and hydrostatics, it is our main partner. Poclain supplies the hydraulic engine for moving the internal auger on the single-auger machines.