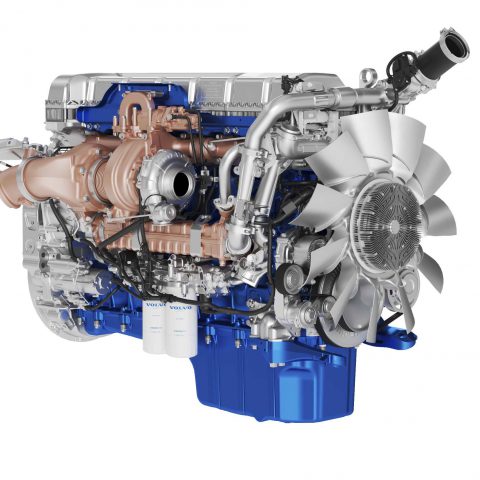

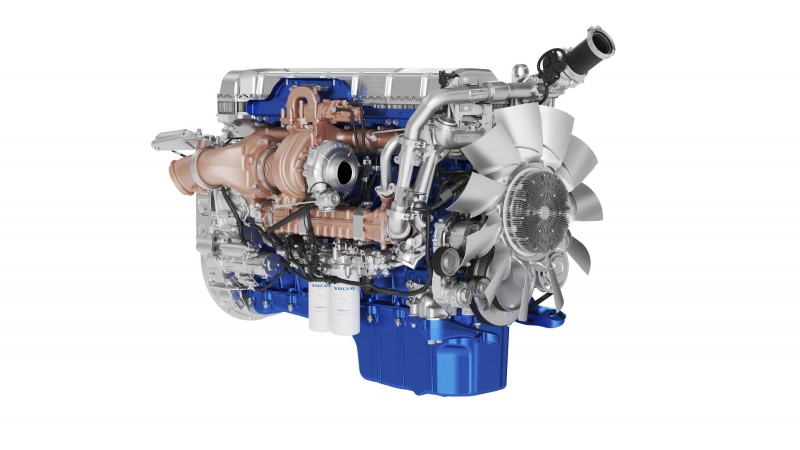

Volvo D13TC with I-SAVE package (and turbocompound)

The Volvo D13TC engine features the I-SAVE package, which also includes the turbocompound. That is, coupling the D13TC and the advanced gear management (I-Shift) software with the optimized software for long-range operations (Eco mode), predictive cruise control (I-See) in combination with I-Cruise. And again, the automatic engine shutdown, the variable displacement steering pump, the high-efficiency […]

The Volvo D13TC engine features the I-SAVE package, which also includes the turbocompound. That is, coupling the D13TC and the advanced gear management (I-Shift) software with the optimized software for long-range operations (Eco mode), predictive cruise control (I-See) in combination with I-Cruise. And again, the automatic engine shutdown, the variable displacement steering pump, the high-efficiency differential and the full deflector package. The overall average saving ranges from 7 percent up to 10 percent.

Volvo D13TC and the benefits of the turbocompound

The credit goes primarily to the turbocompound, which is able to transfer to the engine shaft about 300 Nm starting at lower rpm and makes pushing over 1. 600 rpm almost unnecessary.

Compared with traditional versions, this means 25 to 35 kW more or 150 rpm less at the same power rate.

There’s two 13-litre rates: the D13K460TC, delivering 345 kW at 1,900 rpm and 2,600 Nm at 900 to 1300 rpm, and the D13K500TC, 375 kW and 2,800 Nm. As was said, this is the same power rate of the version without turbcompound but delivering 300 Nm more.

Less torque but a lighter engine

And even if you dare to compare the base rate of her majesty the D16K (405 kW with automatic transmission), when it comes to torque, the D13K500TC shows just 100 Nm less but is 238 kg lighter, since its setup weighs just 100 kg more compared to the traditional 13 liters.

Leaving aside the performances, this solution overcomes some limitations of the turbocompound, an interesting technical solution showing some quite significant problems. The main one is due to the second turbine, which causes a counterpressure that worsens the fluid dynamics of the exhaust phase and – especially at low rpm or partial loads a return of exhaust gases to the combustion chamber. The latter had a positive effect in the first turbocompounds because it was, in fact, a negative recirculation in terms of performance, to the point of having in those conditions a zero or even negative impact on the overall power rate.