Volvo G13. Gas thinks as a diesel

Volvo G13. Part of natural liquefied gas 13 liters for heavy trucks, Volvo wore the shirt of the ‘false striker’. This role comes from its peculiarity compared to the ‘classic’ wing roleplay of this recently formed trio, Cursor by Fpt Industrial and Scania, which use Otto cycle: here we find a Diesel cycle featuring gas […]

Volvo G13. Part of natural liquefied gas 13 liters for heavy trucks, Volvo wore the shirt of the ‘false striker’. This role comes from its peculiarity compared to the ‘classic’ wing roleplay of this recently formed trio, Cursor by Fpt Industrial and Scania, which use Otto cycle: here we find a Diesel cycle featuring gas injection in the combustion chamber over 90 percent, in compliance with approval criteria, in order not to be classified as dual fuel.

Mixing savings and efficiency

How is it possible? The path was opened by Rudolf and its name is efficiency, providing a gap between 15 and 25 percent compared to an Otto cycle, embracing an outlook that could be attractive for some industrial heavy-duty applications. The basic idea is keeping the optimization of mechanical energy on wich Diesel cycle is based and make it compatible with a more harmless fuel regarding nitrogen oxides and fine dust. This result was achieved without sacrificing torque, which in 338 kW (460 HP) calibration is delayed only 100 rpm, unlike the 309 kW (420 HP) which follows the same torque curve of the Diesel version. The Diesel cycle, moreover, allows using the engine brake, taking out only a few kW at 1,000 rpm, hence with engine brake in idle mode, while operating over 1,500 rpm.

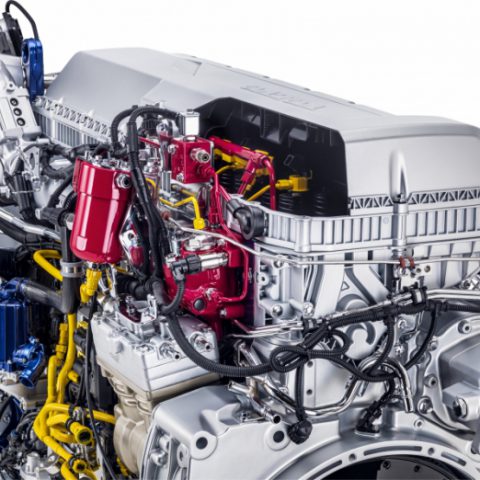

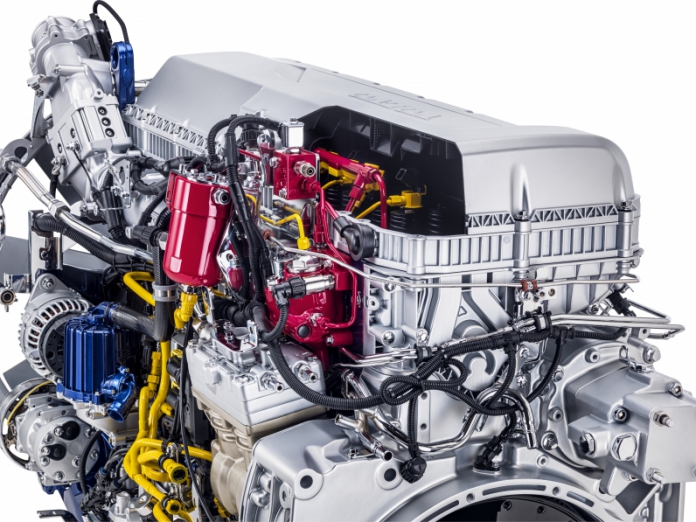

A siren, that of ignition diesel, which ‘deceives’ the control unit along with common rail, modified to use both fuels. That’s why this is a very, very peculiar Diesel. The D13 stays faithful to its nature, the monobloc is the same of the historic 6-cylinders ‘Full diesel’, some changes on the cylinder head have been made to adapt to the specific common rail and injection pump. First of all, the common rail delivers a kind of “pilot” injection, and when the combustion is not yet at the top dead center and the flame face is started the peculiarity of the G13 comes in. The double chamber of the common rail – featuring a non-perfectly circular section inject methane in gaseous state that is then in the appropriate pressure and temperature conditions to ignite.

That’s because the tanks are cryogenic, the store fuel is liquefied natural gas, but the nebulization in the combustion chamber takes place when the gas is compressed again.

Volvo G13. Injection features

The injector features a concentric and coaxial body and the pressure is driven by a pump immersed in the LNG tank, which aspires the liquid fraction bringing it to the upper section, where engine cooling water is flowing inside a serpentine acting as an heat exchanger and heating the line of liquid methane in order to convert it to the gaseous state.

A five-liter module acts as storage unit sending compressed methane to the engine at 300 bar. This accumulator is called Igm, and we could call it an “automatic translator” which links diesel and gas in order to balance the delivering of the two fuels. To allow this transformation Volvo “think tank” used a PTO which drives the hydraulic circuit.

As we said, the system only works if the Diesel conditioning module correctly calibrates the amount of diesel. In case of overflow Dcm controls the return to the tank. In the same way, to avoid non-combusted methane dispersion, slip methane risk must be avoided. The Return to tank excludes any possibility of unburned gas dispersion: the excess methane is cooled through a nozzle and returns to the tank in liquid state.

Maximum loss of methane allowed during the operating cycle is 0.5 g/kWh. Volvo chart draws a value of 0.30 g/kWh in the harshest condition of use. Taking into account the rarefaction of liquefied natural gas distribution network, the G13 has an ace up his sleeve to manage emergencies. Once the gas is finished there’s still a small reserve of diesel fuel which is not used for power but, as we know, as a “primer” of the flame face, capable to provide 50 HP (36.7 kW) at 20 km/h.