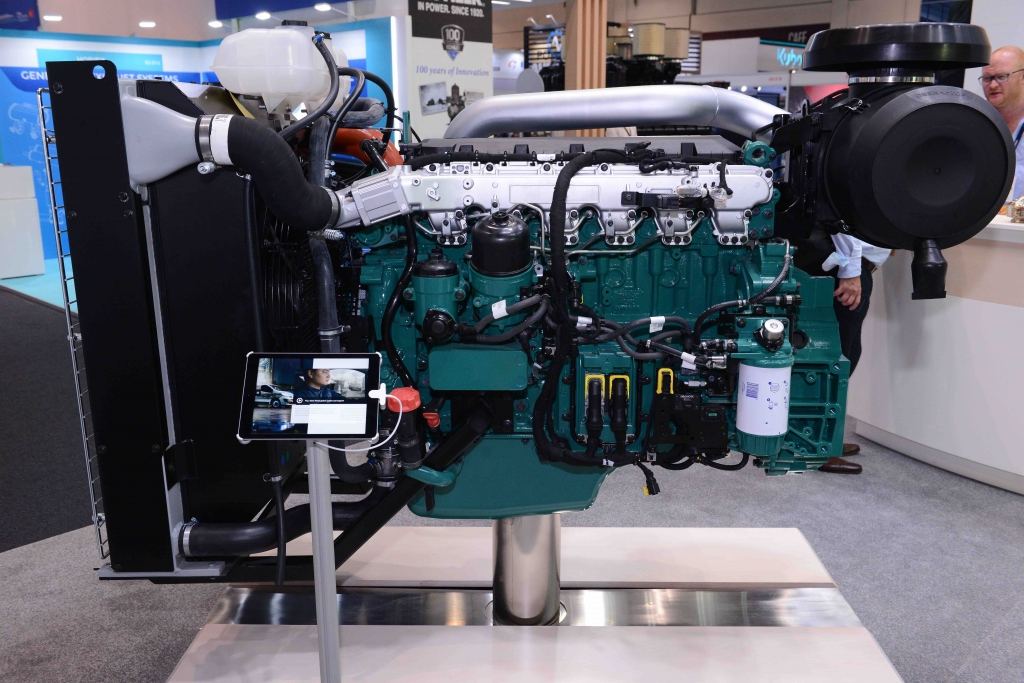

Volvo Penta D8 Stage II and Stage IIIA PG engine, in details

Volvo Penta D8 Stage II and Stage IIIA engine was on display at Middle East Energy 2020 in Dubai. We had already introduced the new version of the engine, whose Stage V version was presented at the end of 2019 at Key Energy in Rimini. Kristian Vekas, Product manager for generator engines at Volvo Penta, […]

Volvo Penta D8 Stage II and Stage IIIA engine was on display at Middle East Energy 2020 in Dubai. We had already introduced the new version of the engine, whose Stage V version was presented at the end of 2019 at Key Energy in Rimini.

Kristian Vekas, Product manager for generator engines at Volvo Penta, gave us some more interesting details about the D8.

Can you please tell us something more about the whole project behind the new Volvo Penta D8 Stage II and Stage IIIA engine on display in Dubai?

It is a Stage II and Stage IIIA emissions level product. In Europe, we target fixed installations or emergency and stand-by applications. For the rest of the world, such a product has been designed for unregulated markets. We have worked quite much cross-functional on this project, together with our colleagues in the Group, to leverage all the knowledge and expertise in the genset business to make this a perfect genset engine, in terms of load acceptance and TCO.

As this product will be used both as a stand-by engine and on mobile machines, power density is crucial. We have really pushed a lot of power in the size of this 7.7-liter engine, so we can say it’s our best-in-class when it comes to power density.

What do you mean exactly when you refer to ‘100% proven and reliable components’ about the new engine? Is there anything new about the engine key components?

We have adapted our technology to genset applications. Even if, for example, the turbocharger is more or less the same compared to other applications, the one we have on this product has been subjected to some modifications in order to fit genset applications specifically.

Basically, we haven’t started from a blank sheet, but rather from something we already had, making developments to fit new specific requirements.

Our last conversation was in Rimini, about the D8 and D13 Stage V engines for PG. There, we talked about a smoother installation layout. What about the engines on display at MEE?

It’s basically the same engine. Of course, in that case we had a Stage V with a heat management system and, above all, an aftertreatment system. In this engine, we don’t need any of these systems. If you look at the engine only or at its footprint, it’s quite the same. We have kept the same philosophy also in terms of installation layout: this is connected back to power density. The smaller is the engine, the easier it is for OEMs to build the genset.

There are a lot of similarities between the engines: for example, the cooling system and the engine block are comparable in the two versions. From an installation point of view, the Stage II and Stage IIIA are exactly the same compared to Stage V. Of course, the Stage V engine requires more space because of its aftertreatment system.

What are the main requirements coming from customers in the Middle East area? Some specific differences compared to the other less regulated countries (Russia and Africa, for instance)?

Even if the markets are unregulated, we don’t sell or develop unregulated products. That’s our philosophy as a company. The robustness of this engine is probably more crucial in countries around the Middle East area, where there’s a lot of dust or a tougher climate. The engine has been tested to work under very hot climate or dusty environments. The results were really good indeed.

What can you say about possible applications?

It’s actually designed to meet emergency applications. The most important thing as far as emergency applications are concerned, is to start quickly and have a good load acceptance. There’s been a lot of focus on these requirements. It is also suitable for prime power installations, where TCO is maybe more important.