ZF and Freudenberg announce fuel cell drive partnership

ZF’s Commercial Vehicle Solutions (CVS) division has announced a joint development agreement with fuel cell and battery systems supplier, Freudenberg e-Power Systems.

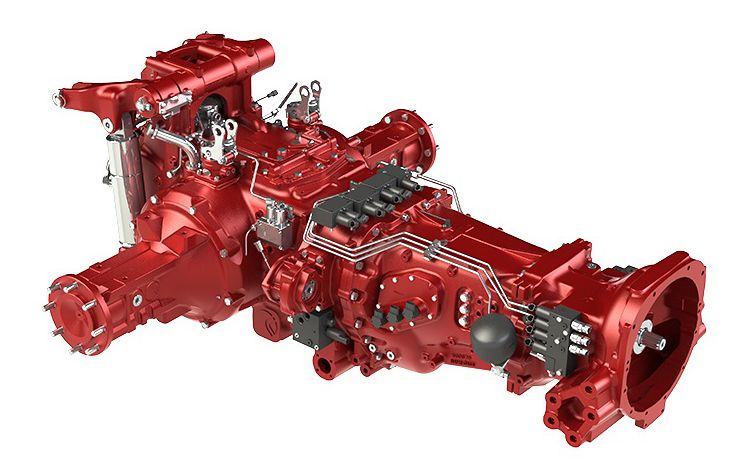

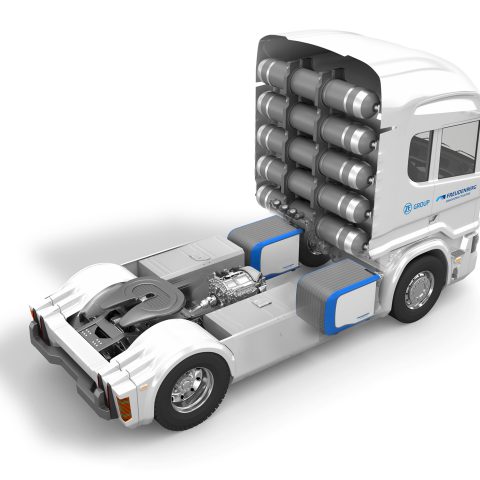

ZF’s Commercial Vehicle Solutions (CVS) division has announced a joint development agreement with fuel cell and battery systems supplier, Freudenberg e-Power Systems. The partners will develop clean e-Drive “powerpack” solutions, consisting of a fuel cell and drivetrain system, as well as share components for a variety of applications. The initial focus of the agreement is to develop a highly integrated fuel cell e-drive solution for commercial vehicles. While Freudenberg will offer scalable e-power systems in kit form with various power outputs, ZF will offer complete electric driveline systems of up to 360 kW continuous power. This is in line with ZF’s new CeTrax 2 electric central drive for heavy-duty vehicles.

“Decarbonization is a major aim of the transport industry, and within this, fuel cell technology will be a game changer. Together with Freudenberg, we can offer a ‘one-stop-shop’ solution enabling manufacturers to quickly bring e-mobility solutions to market and supporting the industry’s transformation towards a more sustainable future,” said Wilhelm Rehm, ZF Board Member with responsibility for Commercial Vehicle Solutions, Industrial Technology and Materials Management. “ZF’s cooperation with Freudenberg will develop highly integrated fuel cell e-drive solutions for the commercial vehicle industry. By reducing manufacturers’ development and project costs, our powerpack solutions will also help to lower the Total Cost of Ownership.”

“We are investing heavily in the mobility of the future. In battery, hydrogen and fuel cell technology as well as in the development of high-tech components for electric vehicles. The long-term cooperation with ZF agreed-upon today underscores the strategic importance and growth potential that we at Freudenberg see in this sector,” explained Mohsen Sohi, CEO of the Freudenberg Group. “Freudenberg and ZF are long-standing, experienced players in the industry and have complementary technology know-how,” added Max Kley, CEO of Freudenberg e-Power Systems. “Through our cooperation, we are pooling this experience to develop clean e-Drive solutions and thus helping support the industry in achieving its climate goals.”

The pilot phase of the cooperation agreement is currently underway with prototypes for bus and truck demonstration vehicles being developed. The first prototype is expected by 2023. This corresponds to ZF’s already announced fuel cell partnership for the development of a coach prototype as part of the HyFleet project.

ZF and Freudenberg: open technology approach for eMobility

When it comes to decarbonization, ZF sees a clear trend towards fuel cell technology due to the longer range and faster refueling times it offers. By 2030, the Group estimates a worldwide share of this technology to be 20% for heavy-duty commercial vehicles. As a result, ZF will continue to take a flexible, open-minded approach to fuel cell technology as a drive solution to support this transformation.

This flexible approach to energy source differentiation is also key to ZF and Freudenberg’s partnership which offers many benefits for manufacturers across the world. Adding a jointly developed integrated fuel cell eDrive to ZF’s comprehensive eMobility portfolio means that all the key electrified hardware and software solutions customers require to transform their product portfolio are available from a ‘one-stop’ source. Eliminating the manufacturers need for costly R&D, project management and reducing integration efforts, the highly integrated eDrive technology promises to help lower the Total Cost of Ownership.

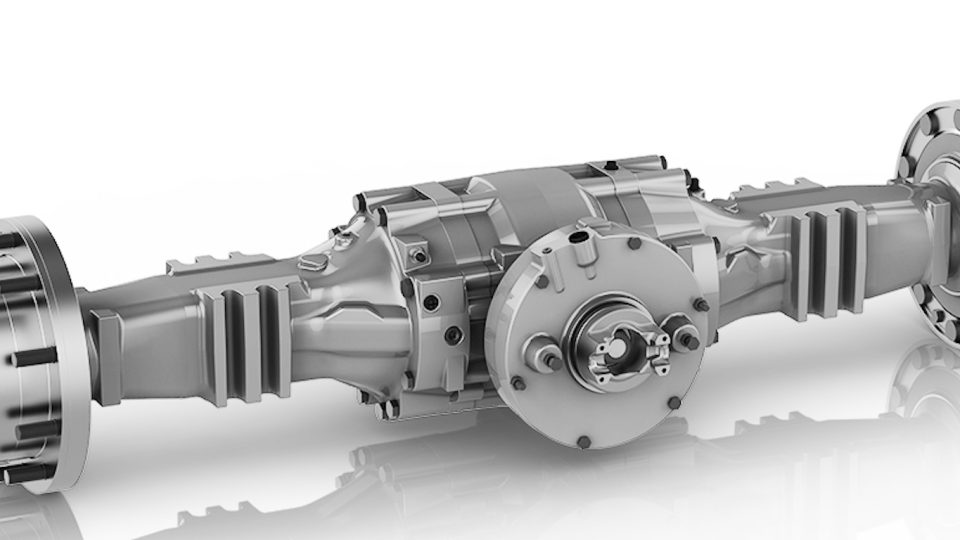

The partnership combines the core competencies of two companies with Freudenberg’s expertise in fuel cell and battery systems and ZF’s electric components including drivelines, inverters, converters, compressors, software Energy Management Systems as well as the ability to integrate and harmonize the systems in between, further enhancing operating efficiency and sustainability.