Fpt Industrial. Between axles and transmissions

Fpt Industrial also deals with axles and transmissions for trucks and buses It all started with the joint venture between Iveco and Rockwell that coincides with the beginning of the Iveco axles history. We are talking about the glorious seventies and we will have to wait until 1991 to see the birth of the drivetrain […]

Fpt Industrial also deals with axles and transmissions for trucks and buses

It all started with the joint venture between Iveco and Rockwell that coincides with the beginning of the Iveco axles history. We are talking about the glorious seventies and we will have to wait until 1991 to see the birth of the drivetrain soul of Fpt Industrial in the city of Turin (Italy). In this city we saw the rise of axles and transmissions for trucks and buses.

Three lines of manual transmissions: 2850.6, 2840.6 and 2835.6, capable of handling torques from 200 to 500 Nm, modulating the transmission based on the driving torque and the application ratios. It all stems from the collaboration with Interpump. The keyword is: efficiency. The objective, in addition to have a low total cost of ownership and a high duration, is to reduce noise, a crucial factor for some types of applications, such as minibuses.

To find a solution, the semi-aenecoic cell intervenes, within which an acoustic analysis occurs according to the ISO standards, to allow the replicability and comparability of the sound spectra. In this particular chamber the wedge-shaped walls have been replaced by sound-absorbing panels.

FINCANTIERI AND FPT INDUSTRIAL

Efficiency and innovation are definitely present

The problem solving phase intervenes when a motor or a transmission shows a high noise and the solution comes from a spectral analysis and algorithms developed to identify defects and anomalies. The rigid steering axles tolerate a load of 3.6 to 18 tons, 30 kNm of braking torque and support vehicles up to 40 tons.

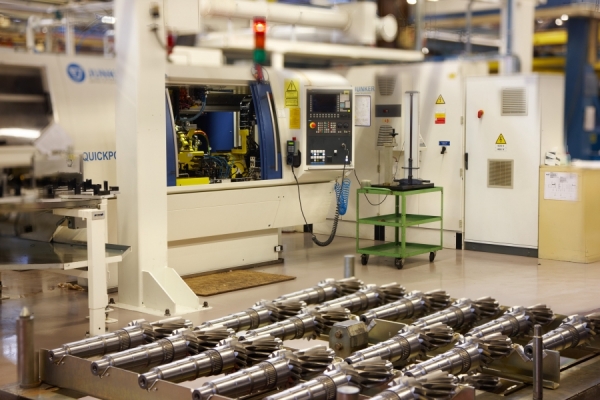

The processing of the spindles changed between 2017 and 2018 and an automatic processing line emerged from scratch (with latest-generation machining centers inspired by industry 4.0 concepts, including the monitoring of fundamental parameters by the operator) with also a new assembly line (which follows the principles of golden zone material, minimum material handling and automatic transport).

In 2017, there was not only the introduction of disc brakes and the X-Way revolution. There was also the end of the lubrication, with the addition of a bearing for each wheel. The X-Way software is able to use the efficiency matrix, calculated according to the Acea procedure, to determine the overall efficiency of the vehicle.