Federal-Mogul at IAA Hannover

CrushShield 2448 and IROX 2 at IAA Hannover Within two months the IAA in Hannover will take place (September 19-27). Federal-Mogul presented two new products that it will launch at the event. The company designed both of them primarily for heavy-duty applications, but versions for light vehicles are or will be available. CrushShield 2448 is a […]

CrushShield 2448 and IROX 2 at IAA Hannover

Within two months the IAA in Hannover will take place (September 19-27). Federal-Mogul presented two new products that it will launch at the event. The company designed both of them primarily for heavy-duty applications, but versions for light vehicles are or will be available. CrushShield 2448 is a new-concept textile fiber sleeve, which guarantees greater protection in case of accidents, against abrasion and in case of impact.

To do this, CrushShield 2448 is equipped with an innovative heat-shrinking structure capable of absorbing and dispersing energy in the event of an accident. The multilayer textile fiber of which it is composed has the dual function of facilitating the dissipation of energy and protecting the nearby components from abrasion. The sleeve thus protects the most delicate and sensitive components such as air conditioning lines, fuel lines, hoses and high voltage cables.

Keeping up with heavy-duty evolution says Gian Maria Olivetti

Gian Maria Olivetti, Chief Technology Officer, Federal-Mogul Powertrain commented on the new product. «Heavy-duty engines are becoming increasingly complex. The number of pipes, hoses, cables and cabling components required to ensure the proper operation of a vehicle also increases. As a global leader in the design of abrasive and impact technologies, as well as innovative textile fiber products, our CrushShield solutions from our Systems Protection division have proven to be effective, in advanced testing, in ensuring impact resistance. and lasting protection for the components».

CrushShield 2448 has a shrinkage factor of 4: 1, and a temperature of 140° is needed to activate it. The life of the components benefits from the increase in density and strength resulting from heat shrinkage. CrushShield 2448 is currently being tested with several global OEMs. Process efficiency simplifies installation in sensitive contexts such as large connectors, brackets and profiles with sharp corners. Tammy Ebersole, Federal-Mogul Powertrain Vice President and General Manager Systems Protection commented on the latest creation. «Easy installation is the real hallmark of CrushShield’s design. Once installed, this product adheres perfectly to the component it protects, eliminating the need for other fixation devices. This reduces the total installation time and the complexity to the customer».

IROX 2

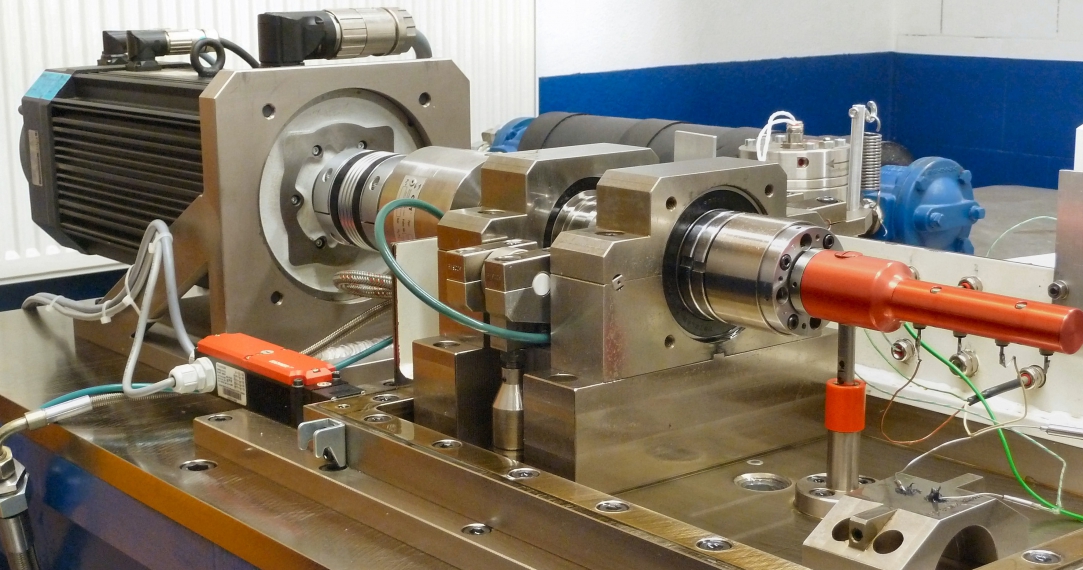

Last year, at the IAA in Hannover, the presentation of the IROX 2 polymer coating for light vehicle engine bearings occurred. Now it’s the turn of the heavy-duty version. The latest product from the IROX family of technologies has successfully passed the tests, displaying significant improvements over previous versions. In fact, they increase performance in terms of seizure and fatigue, especially with steel crankshafts.

Gian Maria Olivetti shows the main advantages. «IROX 2 extends the usage limit for fatigue loads around 100MPa. This limit normally required the use of expensive PVD-coated bearings. By reducing friction, the innovative IROX bearings also contribute to supporting our customers with the goal of reducing fuel consumption and CO2 emissions. Evaluations that derived from the use of test benches developed in-house have shown that the reduction of friction, when using bearings coated with IROX, is higher than that obtained by passing from a 5W30 gradation lubricant to one of gradation 0W20». Compared to the predecessor, designed for crankshafts with a standard surface finish, IROX 2 is suitable for shafts with a much smoother finish that use less viscous lubricants. Significant advantages are perceived, thanks to the adaptability of IROX 2, during the engine break-in phase.

From IROX to IROX 2, a molecular-level upgrade

Both IROX 2 and the previous version prove to be particularly effective in applications on hybrid or start-stop engines. These, explains Stefan Rittmann, Director of Technology, Bearings, Federal-Mogul Powertrain, «stress the bearings even more because of frequent reboots. The bearings have a surface coating in PAI (Polyamide-imide), a polymer resin binder containing a given number of additives dispersed within a matrix. In the development of IROX 2, the changes involved the binder system at the molecular level and small variations in the composition. For example, when compared to IROX, IROX 2 does not contain silicon carbide particles and has a higher content of a synergistic mixture of solid lubricants». All that remains is to wait for the IAA to publicly see the new Federal-Mogul solutions. In fact, in Hannover, the company will exhibit them together with numerous other products.