Atomatika, the robot who chose Perkins

Due to its category 2 three-point hitch, Atomatika, the agricultural robot powered by the 2.2 litre 400 Series Perkins engine, is suitable with a wide range of agricultural implements

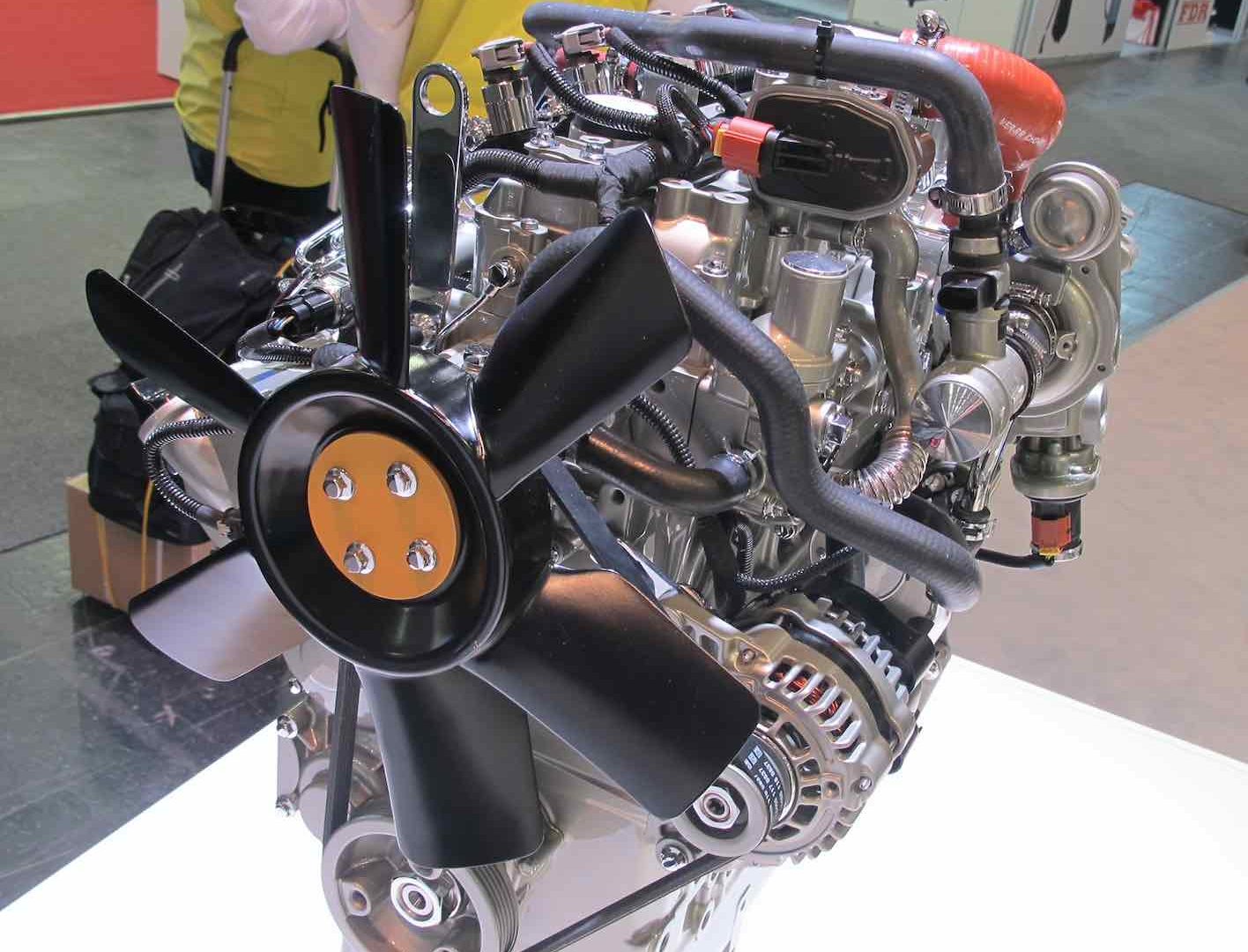

It is called Atomatika and is Agricobots‘ robot powered by Perkins’ Syncro 404, a supercharged 2.2-litre 4-cylinder Diesel engine, at its maximum power output of 55 kilowatts, for 270 Nm at 1,800 rpm. The fuel tank capacity is 60 litres, while the hydraulic oil tank can be up to 75 litres. The electrical system has an operating voltage of 12 VDC. The agricultural robot is controlled via a Scanreco device with a working radio frequency of 2.4 Ghz, and a range of up to 150 metres.

Atomatika and Perkins in the crowded circle of radio-controlled vehicles

There is buzz in the field of radio-controlled machines for agricultural applications, from ditch maintenance, grape-shakers, mini-dumpers and, like the Atomatika equipped with Perkins’ 404, a tracked and autonomous (but remotely controllable) multi-tool, designed to operate in demanding orchards and vineyards.

Completely autarchic (the planning and design are by the designers of Agricobots, an Apulia-based company from Montemesola, in the South-east of Italy, but with its administrative headquarters in Milan, it is ideal for operating on rough and challenging terrain, with slopes of up to 70%. Moreover, carrying a category 2 three-point hitch, it is compatible with a wide range of agricultural implements already in use on most farms. All of this with the transitional period that modern agriculture is going through and that the designers have not hesitated to define as ‘phase 5.0’, in which robotics, artificial intelligence along with augmented reality will play a crucial role (as opposed to IoT systems and decision-support sensors typical of the current ‘phase 4.0’).

He also feels comfortable in the mountains

At 3,378mm long and 1,600mm wide, it has an empty load of 2,400kg. The hydrostatic transmission can make the agricultural robot reach speeds of between 0 and 7 km/h. Despite its size, Agricobots’ autonomous vehicle is capable of working on terrain, as mentioned, with slopes and lateral inclinations of up to 70%. These are high-performance characteristics that make it an ideal tool-carrier for operations in difficult orographic conditions. The robot was exhibited for the first time at Fieragricola Tech, in Verona (Italy) complete with a demountable platform to adapt the vehicle to different operating conditions. Great flexibility, therefore, emphasised by the presence of an optional 800-litre sprayer for phytosanitary treatments. Among the many operations that Atomatika can perform, in addition to those mentioned above, are tillage and mulching.

The autonomous driving system is the KAS (Kinetic Autopilot System) model, with auto-mapping and VRT. Also included at the factory is a touchscreen field tablet with a 10’ screen, satellite geolocation of the machine remotely via a cloud-based platform, and the Agricobots system with extended remote support in telediagnostics for Agriculture 5.0 enablement.