Dellorto two-track strategy

The two-track strategy allows the Dellorto group to extend and customise its expertise in EGR, throttle bodies, power units, BMS and batteries from motorbikes to off-highway applications with long-life requirements

Dellorto has been practically synonymous with engine technology since the era of carburetors. What many may not know is that the Italian company also supplies components for various off-highway engine applications. Its customer base includes FPT Industrial, Mahindra, Rehlko, Tata, SAME, and VM Motori. As Paolo Colombo, R&D Labs & Innovation Manager, explained to us, Dellorto follows a two-track strategy: on one side, strengthening its position in internal combustion applications; on the other, advancing its electrification strategy with the awareness that there is no simple ‘switch on-switch off’ transition.

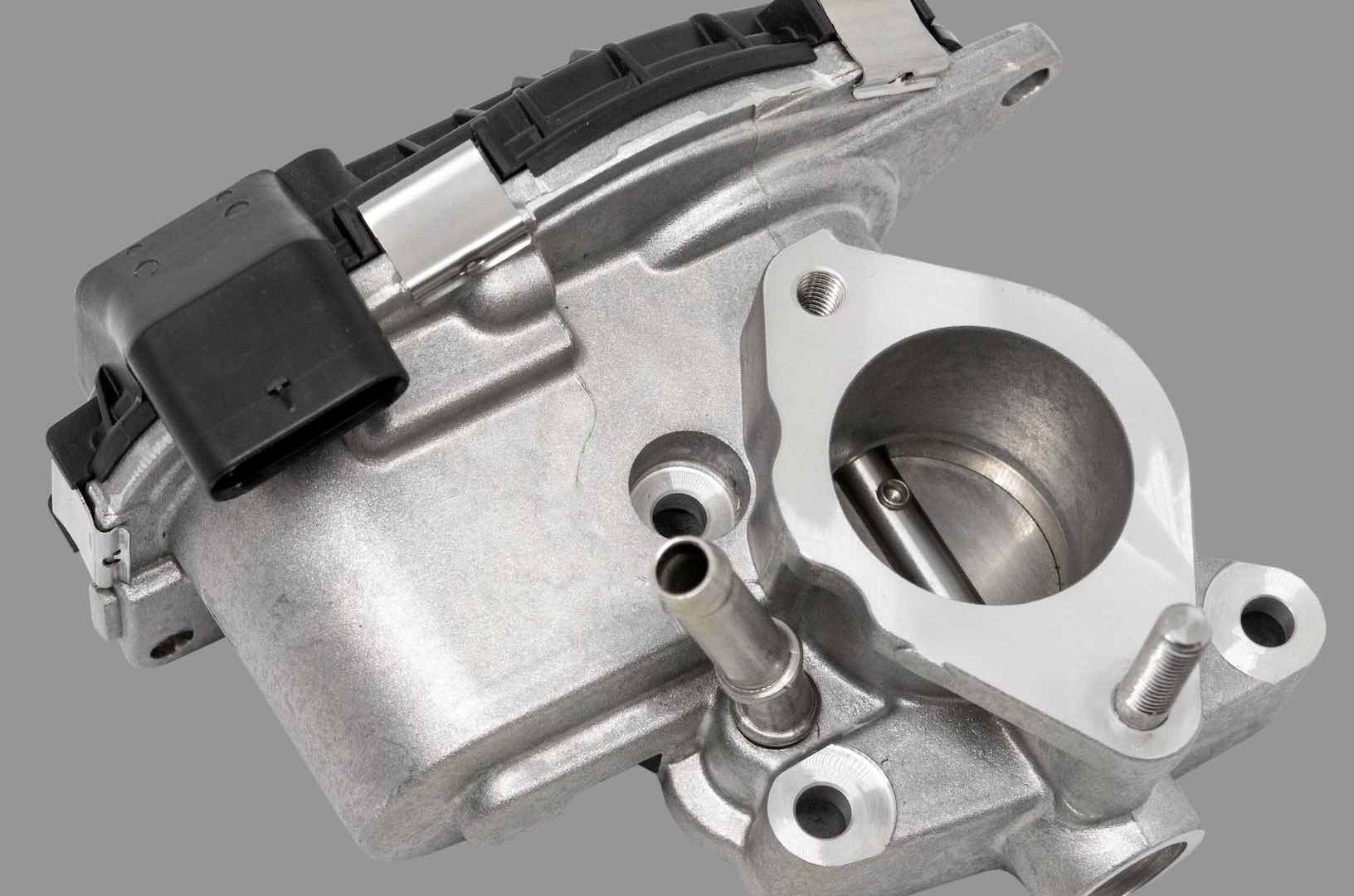

EGR, throttle bodies and more

A foreword is necessary to frame Dellorto‘s contribution. The company approaches customized and innovative solutions with a focus on long-lasting performance, even for small production series. Proactivity, rapid response, and flexibility are deeply embedded in its DNA. Dellorto’s longlife DCm brushed actuators are suitable for both 12V and 24V applications. The company also has expertise in brushless technology (BLDC). Throttle or EGR valve control can be managed through direct drive or a smart-actuator configuration, which integrates position control.

To ensure EGR functionality over the past two decades, the company has developed design and control solutions to prevent or eliminate potential valve sticking. Control strategies, to be implemented in the customer’s control unit, prevent carbon fouling or oxidation on the electrical switch through specific routines activated during engine operation, start-up, and shutdown.

“As EGR flow rates are constantly increasing, there is a rapid shift from the traditional poppet valve to butterfly EGR,” Paolo Colombo stated.

And Dellorto’s expertise extends beyond exhaust gas recirculation valves and throttle bodies. The company also excels in sensor technology: for all electro-actuated valves, they have developed a contactless position sensor. They offer an integrated three-in-one sensor that measures temperature, pressure, and angular position, along with other sensors designed for naturally aspirated and turbocharged engines running on Diesel, CNG, and LPG.

Regarding the second track… electric

For example, on construction sites, Dellorto’s 3kW integrated air-cooled module—housing the inverter, DC-DC converter, and control electronics in a single unit—powers the IMER Taurus mini-dumper. It is available in a 500 kg load version with two batteries and a 700 kg load version with three batteries. The development of the 6 kW power unit is expected to be completed later this year. The powertrain is completed by removable, air-cooled batteries with a nominal voltage of 48V, a capacity of 2.3 kWh, and a weight of 12 kg, which can be recharged using standard 220V sockets. Up to eight batteries can be installed in parallel. The BMS ensures that when used in parallel, one battery acts as the master while the others function as slaves, optimising efficiency.

For fuel cells, Dellorto has developed air supply and shut-off valves for the fuel cell stacks, tailored to the specific requirements of each application. For ICEs, the company has designed specific throttle bodies for hydrogen applications.

Dellorto worldwide

Today, the Dellorto Group operates manufacturing sites in Italy, India, and China. The plant in Cabiate, a few kilometres from Milan, houses the headquarters and the R&D centre. The Italian facility mainly produces electromechanical components and assembles electric power unit kits.

In India, Dellorto has two plants in Pune: one produces components for internal combustion engines, while the other manufactures electronic injection units for motorbikes—a sector in which India is the world’s largest market. To give a sense of scale, in 2024 Dellorto produced 5 million throttle bodies and over a million electronic control units.

In China, Dellorto operates two additional plants in Chongqing: one dedicated to producing fuel pump modules for motorbike applications and the other focused on manufacturing lithium-ion batteries.

Both the Indian and Chinese sites also have teams of engineers who support customers locally in applying Dellorto products. Following its industrial strategy, Dellorto aims to localise production where demand is strongest.