John Deere is developing a biofuel MultiFuel vehicle

While the push for the electrification of tractors proceeds only for those under 100 hp, John Deere takes the field with a solution that enhances the virtuosity of thermal engines thanks to the use of biofuels and their mixtures.

John Deere’s Sustainable Day for the European press, organized in the countryside around Magdeburg last 7 September, represented the ideal opportunity to take stock of the machinery already on the market that john Deere intends to use to carry out its sustainability strategies. Against the backdrop of a large wind farm, among the many technologies shown in the open field near the Landwirtschaftliche Betriebsgemeinschaft Groß Germersleben farm, the MultiFuel engine concept undoubtedly stood out, applied in this case to a John Deere 6155 R.

John Deere also focuses on internal combustion engines

Based on the use of biofuels and also adoptable through a “one-tank” solution (therefore working with any fuel, both in pure and mixed form), it is a particularly interesting technology that, unlike the trends that are being observed in the automotive world for some years now (read electrification), has rekindled the spotlight on the green possibilities that endothermic engines can still offer. In a sector, that of agromechanics, where the energy transition, at least for tractors over 100 horsepower, is still slow for obvious engineering reasons.

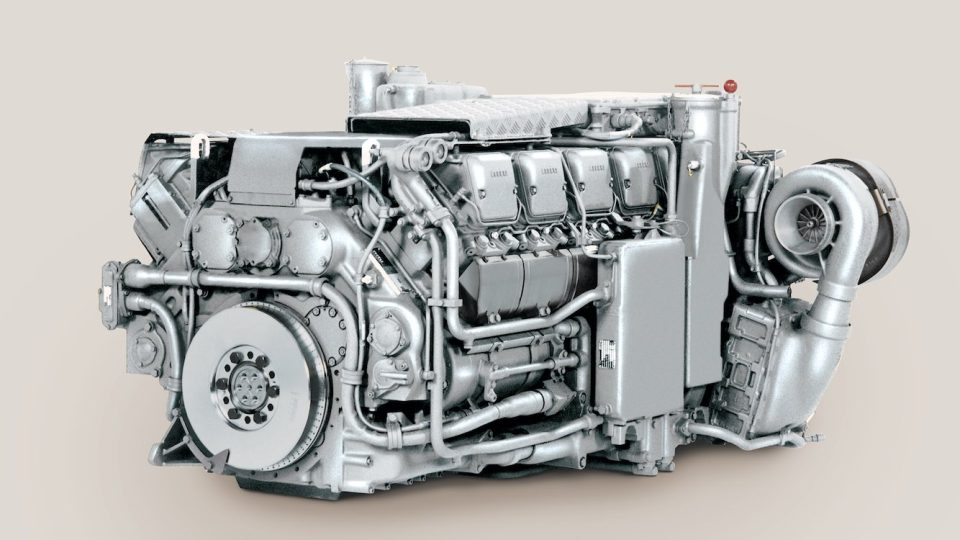

Resulting from the synergies of John Deere, the Straubing Technology and Promotion Center and the University of Kaiserslautern, the MultiFuel engine is part of the “Development and Field Test of an Exhaust Gas Stage 5 MultiFuel tractor (Must5-Trak)” project and allows the agricultural vehicle on which it is installed (in this case, as already mentioned, a brand new 6155 R) to use biofuels (pure vegetable oil, biodiesel, renewable diesel), standard diesel or fuel blends. A project that was also financed by public bodies, including the German Federal Ministry for Food and Agriculture and Fachagentur Nachwachsende Rohstoffe (agency for renewable resources).

An intelligent management of the propulsion system

Several sensors of the standard combustion engine and of the exhaust gas after-treatment system provide data for a mathematical-physical model and for an artificial intelligence-based approach that recognizes different fuel mixtures. On this basis, the electronic engine control unit (ECU) selects the appropriate software setting for optimal engine operation and compliance with the EU Stage V/US Tier 4 emissions standard.

Furthermore, the use of biofuels could bring another great benefit: the process of their production, in fact, generates as a by-product some high quality protein carriers, which can then be used as animal feed and thus replace soybean imports from abroad. Therefore, the use of biofuels does not necessarily conflict with food production. For the introduction of this concept on the market and the use of biofuels in agriculture in Europe, however, the policy framework must create a fair taxation for biofuels in agriculture compared to fossil diesel, which still receives almost all incentives.

This would allow agricultural and forestry activities to reduce CO2 emissions and respond to price volatility or different availability on the fuel market. In this way, EU Stage V emissions regulations can be met with all fuel combinations, thus allowing farmers to use high quotas of renewable and climate-friendly fuels, while increasing the resilience of primary food production through high level of independence from the use of fossil fuels.