Liebherr to showcase its expanded portfolio of combustion engines at Bauma 2025

Some of Liebherr’s new products that we will see at Bauma 2025: a more powerful D9612 diesel engine, the developments in the hydrogen engine carried out by the Components segment, and a concept for an ammonia engine.

At Bauma 2025, Liebherr unveils three innovative product developments in the field of combustion engines, including a high-performing D9612 diesel engine, a cutting-edge hydraulic air boosting system and a concept of an ammonia-powered engine. These advancements underline Liebherr’s commitment to delivering versatile, highly efficient and sustainable powertrain solutions tailored to industry needs.

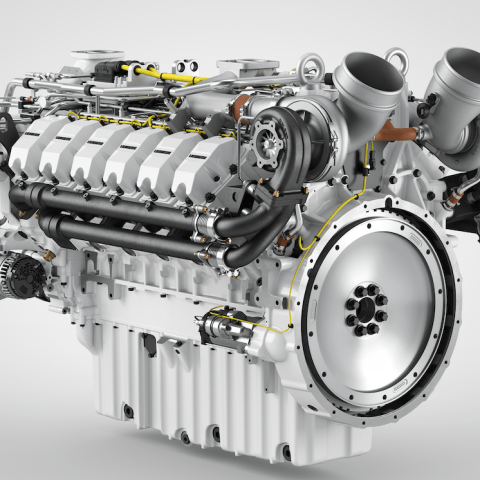

With the launch of a new combustion engine, the D9612, specially developed for demanding off-road applications, Liebherr focuses on agricultural machinery. The D9612 (opening image) delivers a maximum power output of 950 kW and combines robust performance with high efficiency. It is designed to operate reliably under challenging conditions and offers notable improvements not only in fuel consumption, but also in the reduction of emissions. The engine is suited for applications in agriculture, industry and construction, addressing the diverse needs of these sectors. The brand-new D9612 is on display at the components’ booth 326 in hall A4 at Bauma 2025.

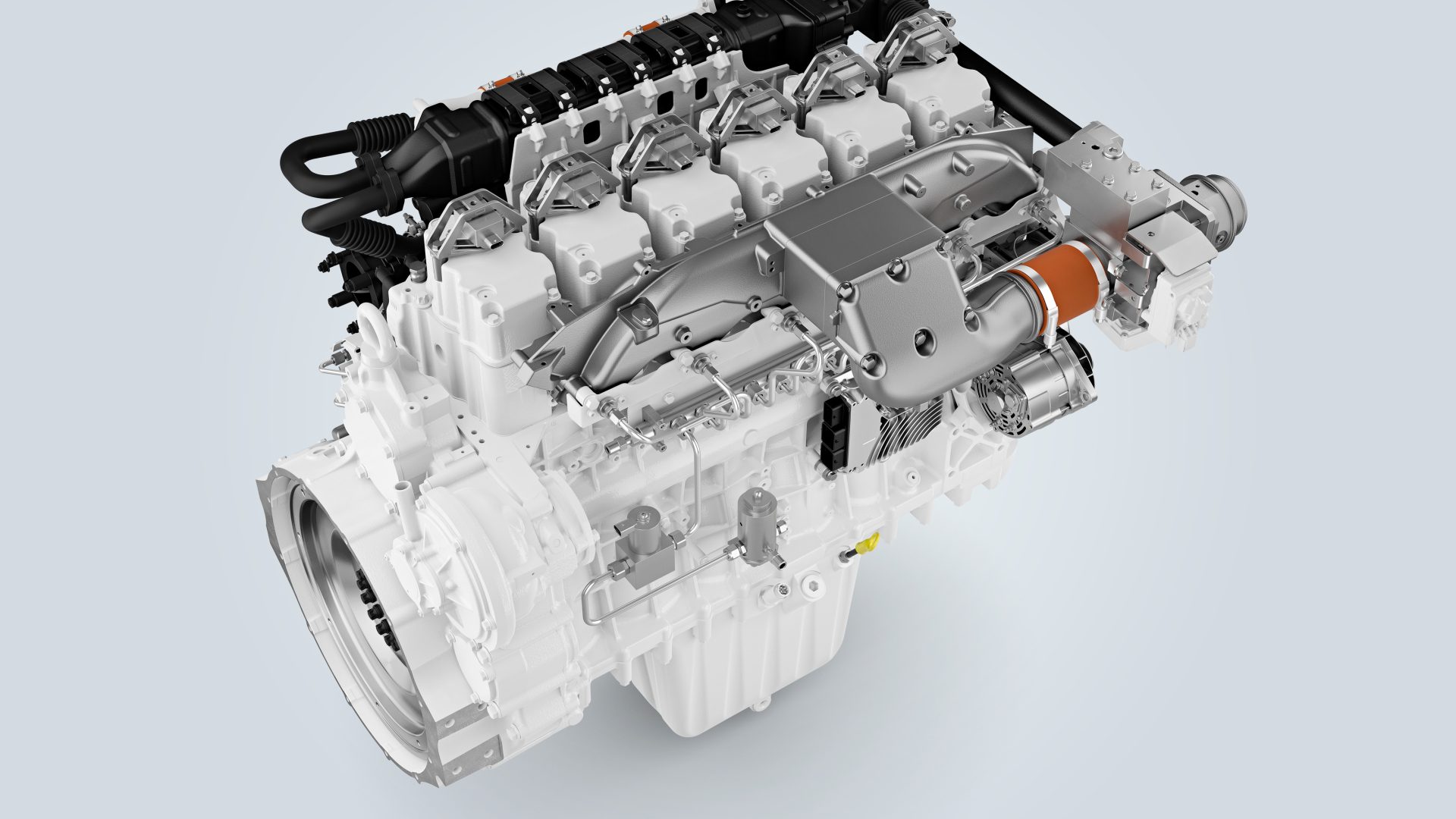

Furthermore, at Bauma Liebherr will display an innovative system: the hydraulic air booster. The system recovers hydraulic energy and uses it to power a mechanical compressor, when needed. When power is required quickly, the system is activated, and the compressor forces additional air into the engine, reducing turbo lag and offering a quicker response to the power demand. The engine can therefore operate at optimal engine efficiency, lowering its fuel consumption. This technology also has the potential to benefit future engines powered by alternative fuels.

Liebherr and the development of hydrogen engines

Liebherr’s components product segment has recently made a significant investment in the development of hydrogen engines and test facilities. Since 2020, prototype engines have been undergoing testing, showing encouraging results in terms of performance and emissions, both on test benches and in the field. Different injection and combustion technologies, such as port fuel injection (PFI) and direct injection (DI), have also been assessed in the process. Initial efforts in the development of a hydrogen engine have considered PFI as a first suitable technology. The 6-cylinder engine prototype H966 (below) that we will see at Bauma is equipped with this technology.

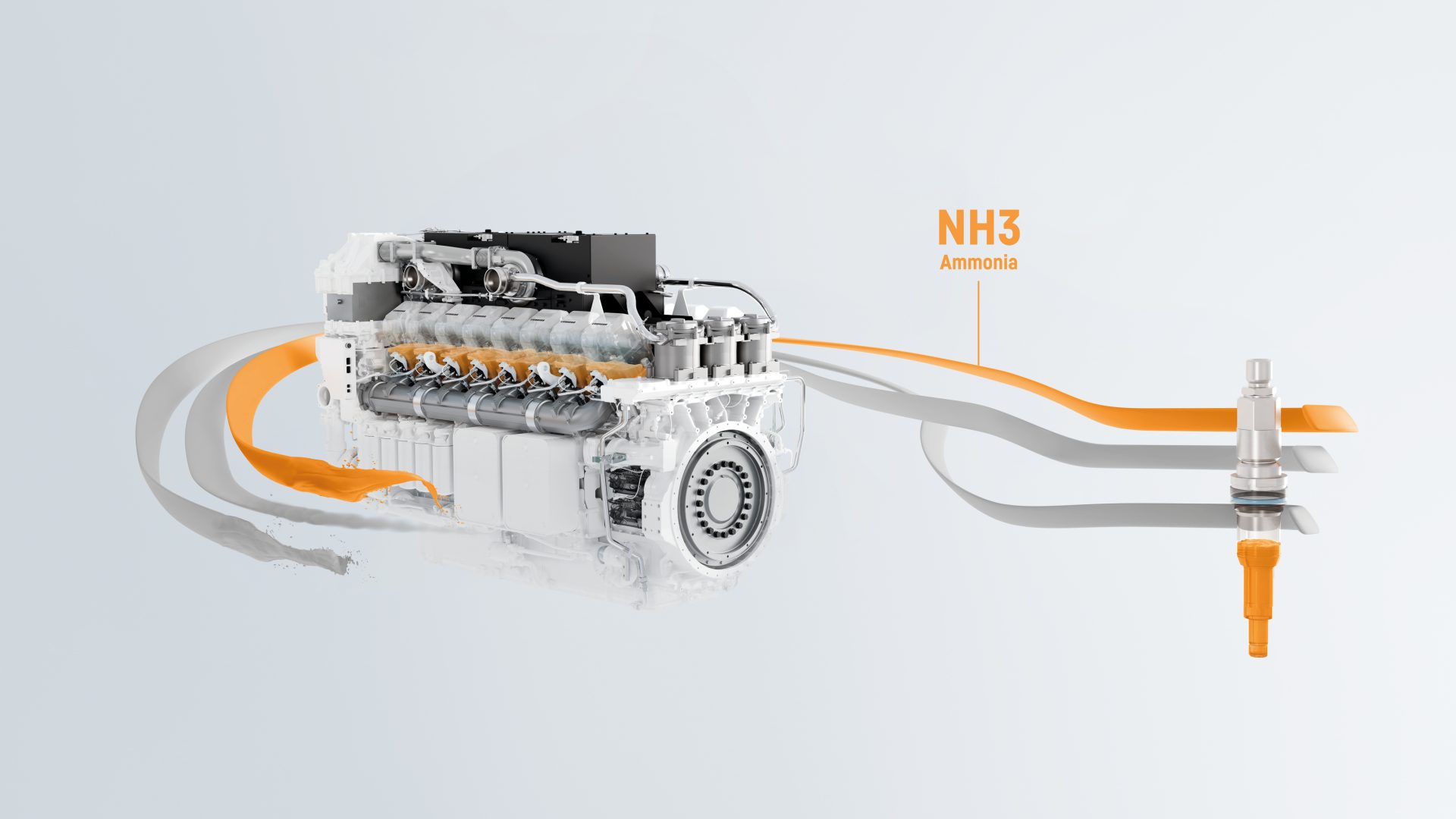

Liebherr towards the future with ammonia

At Bauma 2025, Liebherr is presenting its concept of an ammonia engine (below). Focusing on market requirements, the components product segment has undertaken research activities with ammonia as a power source for dual-fuel internal combustion engines. Generators and potential off-road powertrains fuelled by green ammonia could provide low- or zero-emission solutions for supplementing on-site power supplies. This engine will offer a high efficiency density power in line with the requirements of the mining industry.

Read also: Bruno Generators and Liebherr for green ammonia