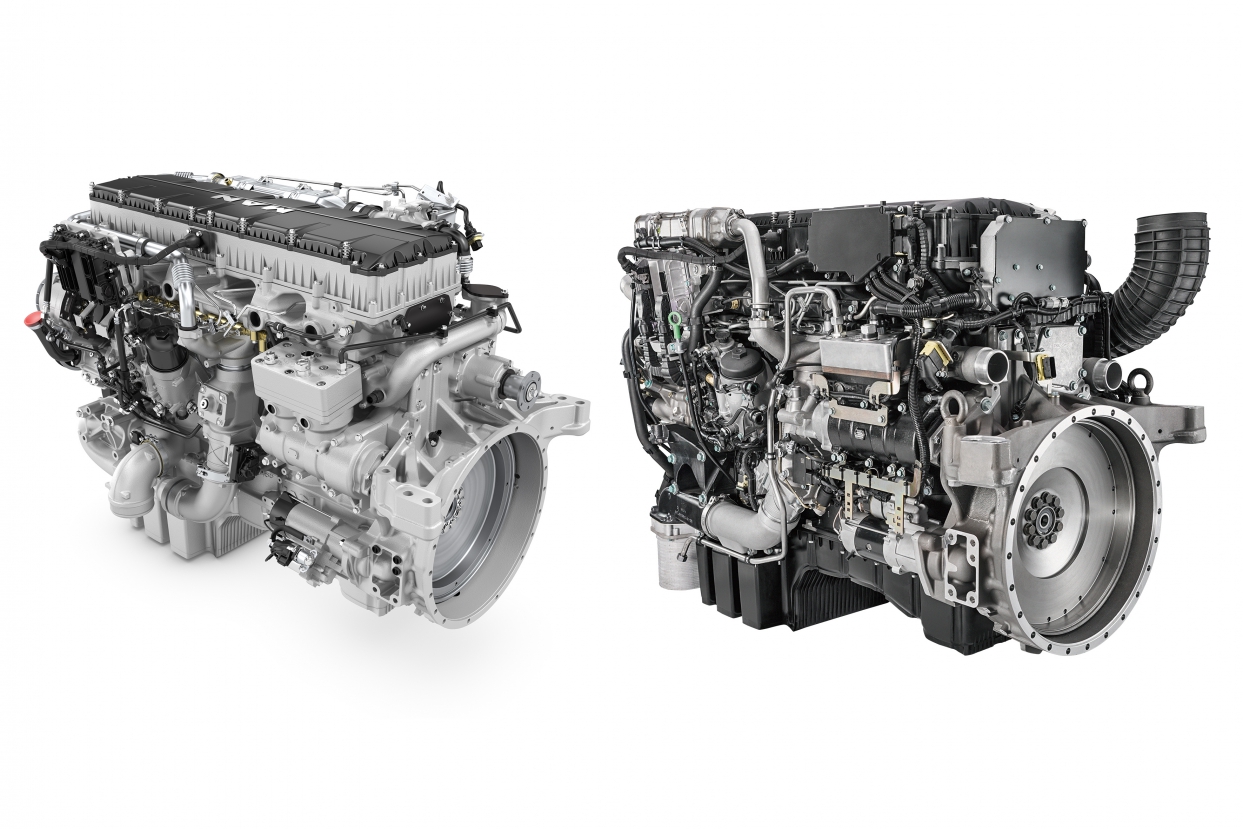

Man D3876, one engine, two “dresses”

Man D3876, one body, two souls. Usually, different applications require different engines, Man figured out how to give more than one destination. In particular, the two versions are meant to be used in truck and off-road applications. D3876, a new milestone The D3876 took the place of a milestone, the D2868, the two-liter per cylinder that […]

Man D3876, one body, two souls. Usually, different applications require different engines, Man figured out how to give more than one destination. In particular, the two versions are meant to be used in truck and off-road applications.

D3876, a new milestone

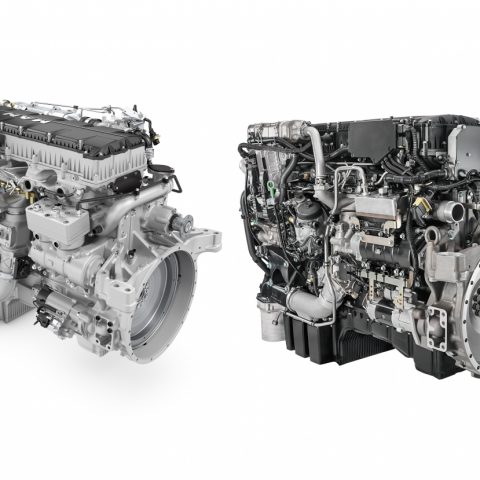

The D3876 took the place of a milestone, the D2868, the two-liter per cylinder that Man developed together with Liebherr. The set of innovations that come with the introduction of the D3876 leave the competitors behind. The off-road version was presented in major off-road events such as those in Munich and Las Vegas. Instead, the industrial one was presented at Agritechnica 2015 and played a dominant role at Bauma 2016. At Baum it won the 2016 Diesel of the Year prize. Choosing to award the D3876 was due to Man’s flexibility in calibrating different technological solutions. First supercharging and exhaust gas recirculation, according to work cycle and specific loads of virtually all applications. The strength and the rigidity of the monoblock in both configurations are the two main features of this engine platform. Gjv-450 vermicular graphite iron base, and to the steel pistons and rods of the cylinder.

The cooling system has “top-down” approach, achieved with a cooling chamber on the head of the cylinder. The head camshaft, driven by a roller lever, and the dome valves, strong of the deformation-proof combustion chamber reinforcement, are also key points.

Two faces of Man D3876

A big difference between the Man D3876 versions consists in the exhaust gas recirculation strategies, to meet emission regulations. The on-road one relies on a double stage for the Egr, one for the low one for the high temperatures ranges. This means a recirculation of up to 40% of unburned gas. For the off-road, Man opted for single stage Egr. On highway applications, maximum power at a stabilized engine speed is privileged on cycles. In the fields and construction sites a diversified torque is demanded to overcome environmental impact concerning soil roughness, air filtration, thermal excursion and high-altitude air related derating, as well as to power attachments. In other words, specific curves require elasticity, and that’s why off-road applications do not make use of the two cooling stages.

Superchaging

Talking about supercharging, the second key feature after recirculation in terms of versatility, the off-road versions mount an implemented variable geometry single turbo to meet the requirement of air volume in the combustion chamber. The reason is the plurality of application variables, that results in different stress peaks and load modulations of the off-road working cycles.