Perkins 2506J Stage V engine for the top-notch Doosan crawler excavator

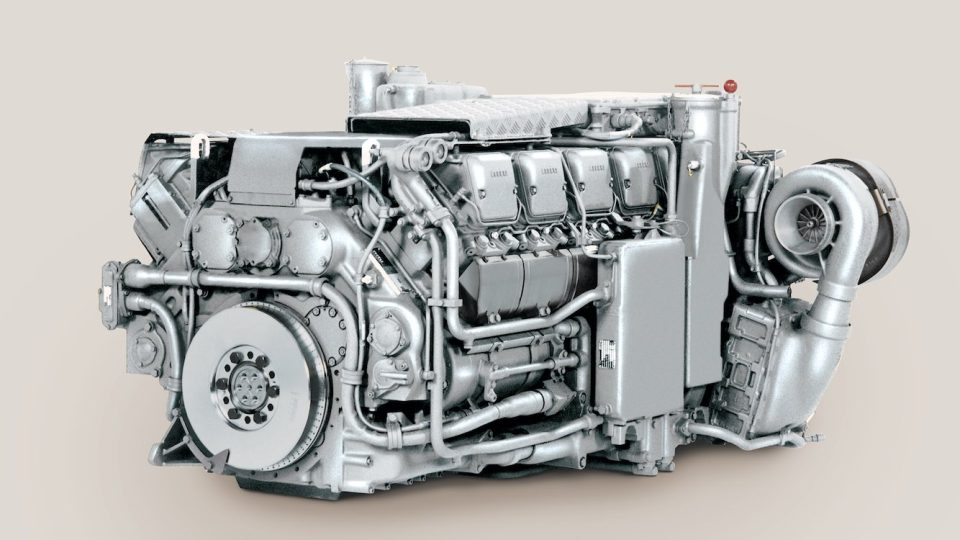

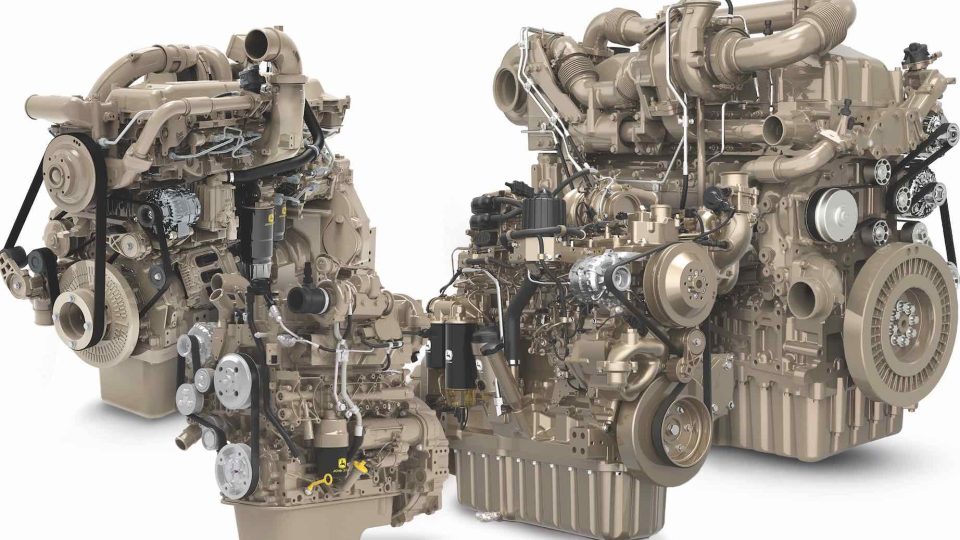

The reliable Perkins 2506J Stage V engine (here’s what the British giant presented at the last bauma, in 2019) was chosen by Doosan to push the new top-notch crawler excavator, standing at the highest part of the extended range of crawler excavators made by the Korean manufacturer, now ranging from 1 to 80 tons. We […]

The reliable Perkins 2506J Stage V engine (here’s what the British giant presented at the last bauma, in 2019) was chosen by Doosan to push the new top-notch crawler excavator, standing at the highest part of the extended range of crawler excavators made by the Korean manufacturer, now ranging from 1 to 80 tons. We talked about such a machine in the November issue of Diesel International: here’s the link to the full article.

The model we are talking about is the DX800LC-7, with almost 80 tons operating weight that matches a 4.6 cubic meters bucket capacity and a digging force of 37.6 tons (bucket) and 33.5 tons (boom).

The new Doosan excavator is intended for «mining and quarrying applications, removing overburden and loading large amounts of material into articulated dump trucks or rigid frame trucks. The DX800LC-7 may also be operated on large construction and infrastructure projects, particularly where considerable amounts of material need to be excavated and stockpiled or loaded into trucks to be moved».

Perkins 2506J Stage V engine: the aftertreatment system

Also and especially thinking about this – but of course without neglecting sustainability – Doosan chose the Stage V version of the reliable Perkins 2506J engine, delivering slightly more than 400 kW (403, to be precise) at 1,800 rpm. This entails an aftertreatment system which includes EGR valve, SCR, DOC – diesel oxidation catalyst – as well as a particulate filter (DPF) – which according to Doosan «automatically regenerates every 25 hours and the excavator continues to work unaffected during this regeneration phase. The operator can check the status of the DPF via the display on the gauge panel in the cab».

Carefully selected component suppliers

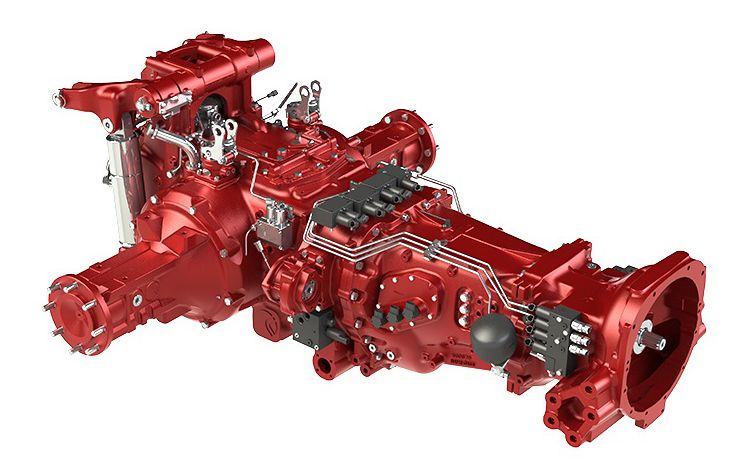

Also, worth mentioning is the collaboration between Doosan and carefully selected component or accessory suppliers. Three names above all, the Italian Berco for the undercarriage, Doosan Mottrol (here Doosan plays at home…) for the rotation mechanism and finally Bosch Rexroth for hydraulics key components, improved to match hydraulic flow with the great power delivered by the engine. We refer in particular to the main pumps and the distributor which we delve into in a specific box.