Scania’s V8 engines sales blocked by a strike

Scania V8. A strike in the supply chain blocks deliveries Scania V8 engines are a guarantee for the Swedish giant’s customers. However, a problem that has temporarily blocked its sale and deliveries has recently arisen. In early July, Scania released an official statement saying that this is due to the continued strike happened at a […]

Scania V8. A strike in the supply chain blocks deliveries

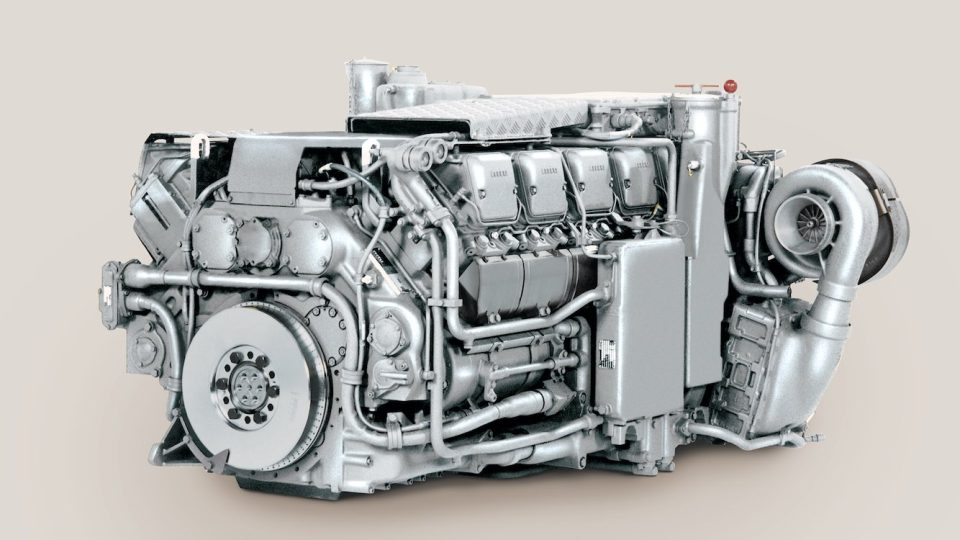

Scania V8 engines are a guarantee for the Swedish giant’s customers. However, a problem that has temporarily blocked its sale and deliveries has recently arisen. In early July, Scania released an official statement saying that this is due to the continued strike happened at a component supplier.

The ongoing strike with a key supplier of cast components for its engines is preventing Scania from delivering more than 2,000 trucks ordered with V8 engines globally. Sales of marine and industrial engines are also affected. The strike lasted from 14 June but already earlier this year this specific supplier had interrupted deliveries, creating chaos in the supply chain.

V8 engines are an important part of Scania’s DNA, says Christian Levin

Christian Levin, Executive Vice President of the Head of Sales and Marketing, issued a statement on the current situation. «I am deeply sorry for this situation that prevents us from supplying our V8 engines, which are a reference on the market and are an important part of Scania’s DNA. Our commercial organization has already started to propose alternatives that allow the customers involved to meet the commitments made with their customers, using our 13-liter engines or other solutions of products and services. Nothing will be left unturned, in order to maintain the trust of our customers».

«It’s a partnership that has lasted for more than 20 years what we have with this supplier». With these words, Anders Williamsson, Executive Vice President of the Head of Purchasing, commented on the event. «Now we are doing everything possible to restore and optimize the supply chain in order to avoid further inconveniences to our customers».

NANNI DIESEL AND SCANIA STIPULATED AN AGREEMENT ON ENGINES FOR PLEASURE BOATS

Scania V8 and Euro6 regulations

Scania updated its Euro6 range, also in order to meet European Stage V, from which it does not differ too much. Concerning the V8 range, the introduction of the Rotated Twin Scroll Fgt turbocharger represents the most important update. The most significant change regards the separation of the exhaust manifolds that arrive at the blower, whose turbine side is now fed separately from the two cylinder banks by separate entrances. Three revised calibrations, under 537 kilowatts (730 horsepower). 478, 426 and 382 kilowatts.

The analogy with the Stage V is that there is no EGR. These engines use only the SCR for the exhaust after-treatment. In detail, the new generation of V8 provides a compact and fully integrated exhaust silencer for after-treatment, which contains an oxidation catalyst, an AdBlue mixer, two short particle filters and with asymmetrical walls to reduce back pressure, three catalysts SCR in parallel and three catalysts ASC.

The air intake ducts have a more linear shape and the fuel is sent to the cylinders via a high-pressure main rail from which the individual pipes of greater length depart. This solution simplifies maintenance work. In addition, thanks to the SCR, the maximum pressure of the fuel injection system has been reduced to 1,800 bar.

When the fuel arrives in the cylinders through the newly developed injection system, with the aid of a high-pressure Xpi pump with only two pistons, more compression and a maximum cylinder pressure of 210 bar are applied.

To ensure a longer service life and reduce internal friction, the cylinder head, pistons and pins, crankcase, crankshaft, and bushings were revised. All of these changes have been made within the Scania modular system and as a result, most of the components will be in common with the Swedish company’s other engine platforms. According to Scania engineers, the integrated upgrade would guarantee fuel savings of 7-10 percent.