Volvo Penta: driving net-zero goals in material handling

Volvo Penta’s multifaceted net-zero ecosystem helps customers navigate the complexities involved: securing uptime and productivity while providing a comprehensive support system across the value chain.

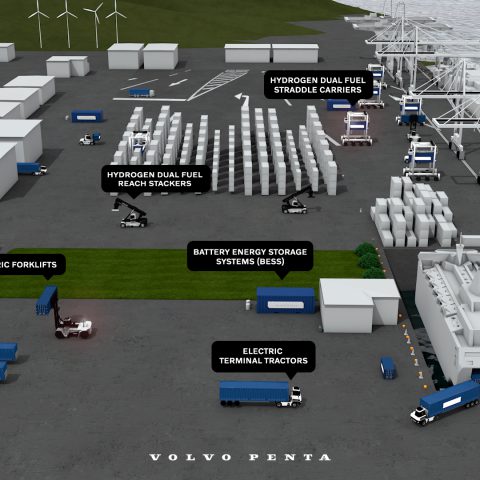

When it comes to material handling operations in ports and terminals, there is simply no silver bullet for CO2 reduction. Instead, achieving net-zero emissions requires a multipronged approach: an ecosystem that caters to all the stakeholders involved, and that combines different strands of expertise to find the best possible solutions.

Electrification and alternative fuels play a key role in making this transition not just possible, but an everyday reality. Material handling operations in ports and terminals are intense and complex, meaning that all of its applications – terminal tractors, reach stackers, RTG cranes, etc. – have to work smoothly, reliably, and sustainably too.

Volvo Penta’s application-adaptable electrification platform is modular, scalable, and purpose-built to keep emissions to a minimum while ensuring uptime. It is designed to be compatible across different industries and applications. In a material handling context, that includes terminal tractors, RoRo tractors, forklifts, straddle carriers, to name a few.

Volvo Penta has a strong legacy designing and delivering reliable combustion engines that are homologated to meet and exceed emissions standards around the world (incl. stage V / Tier 4 final). Their dual-fuel engines mark the next progressive step towards net-zero, following the introduction of HVO; for several years, all Volvo Penta engines are approved to run on HVO.

Next-generation dual-fuel engines and collaborative development

Dual-fuel hydrogen-diesel engines run primarily on the renewable fuel source hydrogen. If hydrogen is not available, the Volvo Penta dual-fuel engine can run on diesel or HVO instead, thus ensuring uptime and stable material handling and port operations.

Volvo Penta’s net-zero ecosystem is about much more than merely supplying OEMs and their customers with power to their equipment and applications. These solutions are realized through successful strategic, technological, and operational synergies: partnerships with customers, technical partnerships (see the latest dual-fuel hydrogen-diesel engine developed with CMB.Tech), customer support system.